RESEARCH, KAWASAKI STYLE

The Story Of A New Motocrosser And A Precedent-Setting R & D Facility That Made It Possible.

JODY NICHOLAS

IT HAS TAKEN only a few years for the Japanese to win the lion’s share of the U.S. motorcycle market with an often original, low cost and reliable product.

Yet, in some areas they have missed the boat. They invented the mass street/trail market (more specifically, Yamaha did), and yet have never wrested the title of absolute superiority away from the European makers of motocross and all-terrain machines.

The Japanese are winning motocross races, now, but have yet to offer real “works” replicas to the general public as do the European firms.

Now Kawasaki has decided to do something about it, and take care of two other items of business at the same time. First, to respond to the fact that one of its major competitors has been cleaning up in international motocross. Second, to design and build motorcycles which are custom-tailored to American needs and tastes.

Kawasaki. Builder of ships, boats, planes and lately motorcycles. Builder of the 750cc Mach IV, which is probably the quickest production roadster sold in the world. Builder of the dohc 900 Four, which will undoubtedly turn a few heads (and a few bank loans). That Kawasaki feels that it has a chink in its armor.

Thus the American distributing arm-Kawasaki Motor Corp.—has gone to great expense and trouble to institute what amounts to the first full-fledged Japanese R&D facility on U.S. soil. It’s part of a trend, of which you’ll see more from other foreign manufacturers.

The lines of communication are more directly with Japan than they are with the U.S. sales group. The original concept for new Kawasakis to be introduced years hence is being born and tested right here in the U.S.

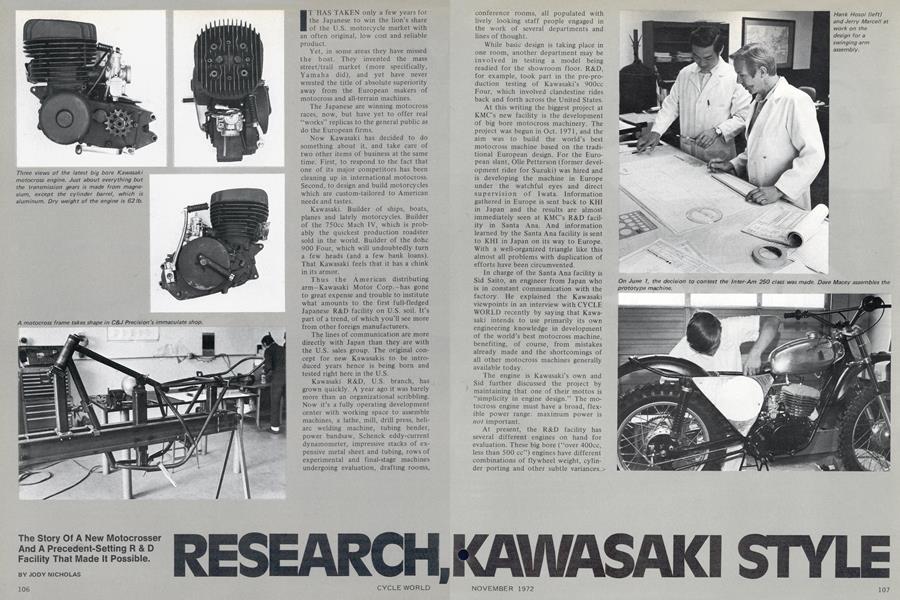

Kawasaki R&D, U.S. branch, has grown quickly. A year ago it was barely more than an organizational scribbling. Now it’s a fully operating development center with working space to assemble machines, a lathe, mill, drill press, heliarc welding machine, tubing bender, power bandsaw, Schenck eddy-current dynamometer, impressive stacks of expensive metal sheet and tubing, rows of experimental and final-stage machines undergoing evaluation, drafting rooms, conference rooms, all populated with lively looking staff people engaged in the work of several departments and lines of thought.

While basic design is taking place in one room, another department may be involved in testing a model being readied for the showroom floor. R&D, for example, took part in the pre-production testing of Kawasaki’s 900cc Four, which involved clandestine rides back and forth across the United States.

At this writing the biggest project at KMC’s new facility is the development of big bore motocross machinery. The project was begun in Oct. 1971, and the aim was to build the world’s best motocross machine based on the traditional European design. For the European slant, Olle Petterson (former development rider for Suzuki) was hired and is developing the machine in Europe under the watchful eyes and direct supervision of Iwata. Information gathered in Europe is sent back to KHI in Japan and the results are almost immediately seen at KMC’s R&D facility in Santa Ana. And information learned by the Santa Ana facility is sent to KHI in Japan on its way to Europe. With a well-organized triangle like this almost all problems with duplication of efforts have been circumvented.

In charge of the Santa Ana facility is Sid Saito, an engineer from Japan who is in constant communication with the factory. He explained the Kawasaki viewpoints in an interview with CYCLE WORLD recently by saying that Kawasaki intends to use primarily its own engineering knowledge in development of the world’s best motocross machine, benefiting, of course, from mistakes already made and the shortcomings of all other motocross machines generally available today.

The engine is Kawasaki’s own and Sid further discussed the project by maintaining that one of their mottos is “simplicity in engine design.” The motocross engine must have a broad, flexible power range: maximum power is not important.

At present, the R&D facility has several different engines on hand for evaluation. These big bore (“over 400cc, less than 500 cc”) engines have different combinations of flywheel weight, cylinder porting and other subtle variances.> There doesn’t seem to be one hard and fast rule regarding the internal dimensions of a successful motocross engine, but Kawasaki is looking for the best combination.

As it now stands, the racer frames are produced by C&J Precision, which is located almost next door to the R&D shop. Jerry Marcell, ex-AMA flat track racer and graduate engineer, is in charge of engineering development and commented thusly: “We know all about the successful motocross machines being produced in the world. Rake, trail, steering head angle, center of gravity, etc. All these dimensions fall within fairly close parameters, but we feel there is room for improvement, both in chassis design and in structural materials and fabrication techniques.”

KMC has chosen 4130 chrome-moly mild steel tubing to build the frames out of and for good reason. Because of its extremely high tensile strength, chrome-moly tubing with a thin wall section can be used instead of a thicker, heavier material which is important when the weight of the frame is a consideration.

Heli-arc welding 4130 is certainly the best and strongest way to join two sections of the material if the proper techniques and materials are used. For instance, one firm specializing in the construction of racing car chassis for a number of years has successfully employed methods similar to those used to fabricate the 4130-alloy Kawasaki frames.

Several years ago titanium was being used for certain automotive suspension members, but the elasticity of the material caused failure after failure. 4130 is now the only material being used in that application.

Arguments arise about the desirability of a certain amount of “flexibility” being necessary in a motorcycle chassis for just the right handling qualities and to preclude breaking the frames from vibration or stress loadings imposed by the terrain and rider’s technique. However, a successful chassis can be made out of almost anything if weight is not a primary consideration. And when weight is a consideration, it’s up to the frame’s designer, builder and test rider to come up with the right combination.

Marcell continued, “For example, the location of the swinging arm pivot bolt in relation to the countershaft sprocket and the axle centerline makes an amazing difference, especially with regards to what happens when you open the throttle after landing from a jump.

“With a powerful machine this makes a great deal of difference regarding the technique the rider must use to keep the bike under control. And so forth.... I could go on for hours discussing just how much difference the little things make in the overall picture, and regardless of what the textbooks say, the only certain method is by trial and error.”

Marcel freely admits that not all the best components are manufactured in Japan at the present time. “We are having many pieces custom-made right here in southern California and in other parts of the United States. For example, A&A Manufacturing is making special plastic high-impact fenders for us and the Uni-Filter Co. is aiding in the development of our air cleaner. Bassani Manufacturing helped us muffle the exhaust system’s noise down to an acceptable level for AMA competition, and several other local firms are working with us. But just having the equipment isn’t the whole story.

“You’ve got to have high caliber riders who are not only capable of winning races, but who are able to aid in the development of the motorcycle as a complete entity. We feel extremely fortunate to have Brad Lackey and John DeSoto aiding us in this project. Both are excellent riders who are able to comment and constructively criticize our machinery so that we can make it better. Kawasaki is planning to market a minimum of 200 replicas of the big bore machine for the 1973 season.”

Japanese staff engineer Hank Hosoi is often seen at his desk plugging formulae into the Olivetti computer or working with Jerry on design drawings of component parts. But just as often he’s back in the shop kibitzing over the progress of the machines.

Just as important as a sound machine is having an expert mechanic to make certain everything is in order before going to the race, and making sure things stay that way during the day’s events. Englishman Dave Macey is the chief machine builder and race mechanic. Dave is remembered by enthusiasts as the man who built a 250cc rotary valve, water-cooled V-8 GP racer some time ago, almost entirely by hand. Needless to say, he’s an excellent machinist as well. Dave, Steve Johnson and Chuck Berry prepare and maintain the R&D department’s machines with meticulous care, and the first few outings the Inter-Am qualifiers, have shown the results.

In order to have a staff of qualified people in every department at the R&D facility, KMC hired Tim Smith, ex-racer with many years experience, to be the motocross team manager. The enthusiasm shown by the entire staff is truly amazing as driving by the facility on certain Saturday mornings has shown: the entire crew is there, developing what appears to be the basis for a really successful, available works replica. R5

View Full Issue

View Full Issue