THE VIOLATION OF AN OSSA

ERIC RAITS

Motocross. Enduros. Trailing. They All Bend Machinery. If You Are A Dirt Rider, You Don't Have To Own An Ossa To Benefit From These Preparations. They'll Help You Finish. And If You Have What It Takes, They May Help You Win!

MOTOCROSS violates machinery. The jumps, the mud, the dust, all take their toll. Parts shake loose, wires break, hot metal seizes, chains grind themselves into pieces. Dead motorcycles litter the sides of a racecourse. It's not unusual in a tough motocross to see a 50-percent attrition rate by the day's end. Lots of good motorcycles that should have finished are pushed back to trucks and loaded aboard for the ride home.

Breakage and mechanical failures can be cut dOWfl drastically by adeq ua Ic preparation. But first you have to know specifically what is liable to tall oft. break or fail.

Trou ble s, YOU have to go t hrough I he tct of compel ing. week-in iid week-out, before you know what is going to happen to a iiiachiiie.

My "test bed" for this art ide was an Ossa 250 Stiletto, furnished to me l)y Yankee Motors. I selected it bec~iuse it is representative of the t inc machinery ava i Ia He to the serious, no n-sn p ported amateur. It combines the virtues ot moderate price, not the lowest or the highest tor a 250. wit h good e rfornLince and handling. Parts are also readil~' available. ,

It should he St ressed that t he proVe melit s" made to I he ()ssa :1 pply in several cases to any ot her motocross lihichinc you could buy. Racers. enduro butts, and hard-riding trail ri(lers can all benefit from these suggest ions, regard less of what they ride.

Racing ind tr~uIing Sire similar in niany respcets. i~ failure in eu her enileavor has t he sa me result: e in harrassmnent or some degree ot' danger.

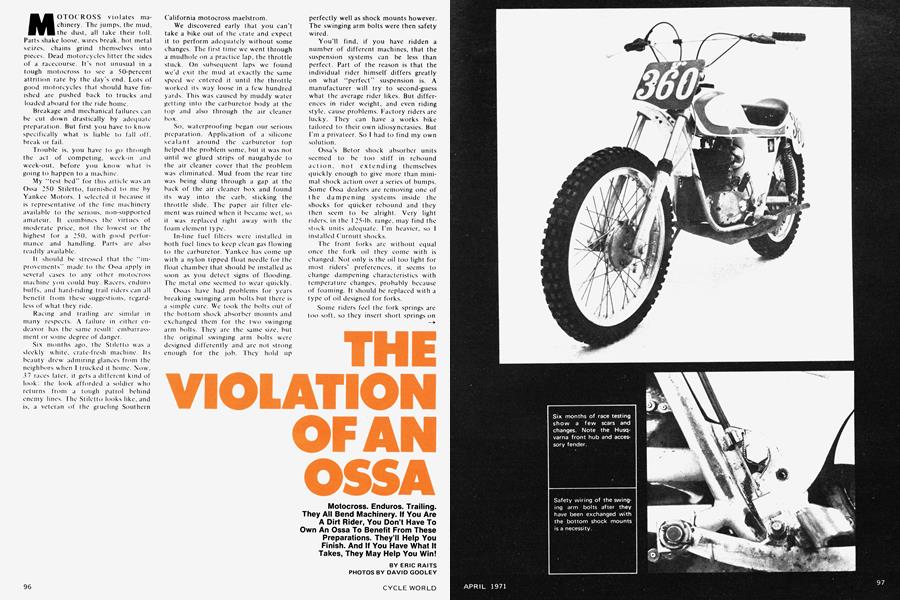

Six months Igo. t he St ilet to was a sleekly white, crate-fresh machine. Its hea ut y drew ad flu ring gi a ii ces tro iii t he neigh hors when I trucked it home. Now. 37 races later, it gets a different kind of look the look afforded a soldier who ret urns I ro 111 a t tnigh Patrol behind enemy lines. The St ilet to looks like, and is. a veteran of t tue grueling Soul hem California motocross maelstrom.

We discovered early that you can't take a hike out of the crate and expect it to perform adequately without some changes. The first time we went through a mudhole on a practice lap, the throttle stuck. On subsequent laps we found we'd exit the mud at exactly the same speed we entered it until the throttle worked its way loose in a few hundred yards. This was caused by muddy water gelt ing into the carburetor body at the tot) and also through the air cleaner box.

So. waterproofing began our serious preparation. Application of a silicone scala nt around the carburetor top helped the problem sonic. but it was not until we glued strips of naugahyde to he air cleaner cover that the problem was eliminated. Mud from the rear tire was being slung through a gap at the back of the air cleaner box and found its way into the carh. Sticking the throttle slide. The paper air filter dc ment was ruined when it became wet. so it was replaced right away with the fo~iin element type.

In-line Fuel filters were installed in hot ii fuel lines to keep clean gas flowing to I he carburetor. Yankee has come up with a nylon tipped float needle for the float chamber that should 1w installed as soon as you detect signs of 1100(11 ng. [he metal one seemed to wear quickly.

Ossas have had problems for years breaking swinging arm bolts hut there is a simple cure. \Ve took the holts out of the hot torn shock absorber mounts and exchanged them for the two swinging arm bolts. They are the same size. hut he original swinging arm 1)01 ts were designed differently a tid are not strong enough for the job. They hold up perfectly well as shock mounts however. The swinging arm bolts were then safety wired.

You'll find, if you have ridden a number of different machines, that the suspension systems can he less than perfect. Part of the reason is that the individual rider himself differs greatly on what perfect" suspension is. A manufacturer will try to second-guess what the average rider likes. But differ ences in rider weight, and even riding style. cause problems. Factory riders are lucky. They can have a works hike tailored to t heir own idiosyncrasies. But I'm a privateer. So I had to find my own SOIL.lti()fl.

Ossa's Betor shock absorber units seemed to be too stiff in rebound action, not extending themselves quickly enough to give more than minimal shock act ion over a series of bumps. Some Ossa dealers are removing one of the dam pe fling systems inside the shocks for quicker rebound and they then seem to be airight. Very light riders. in the I 2~-Ib. range, may find the stot.'k titlits .idequatc. I'm heavier, so I installed (`urnutt shocks.

The front forks are wit hout equal once the fork oil they come with is changed. Not only is the oil too light for most riders' preferences, it seems to change dampening characteristics with einperat nrc changes, probably because ot foam in g. It sho u 1(1 he rep I aced w it h a type of oil designed for forks.

Sonic riders ted the turk springs are Iou soft, so t hey insert short springs on top of the stock units to stiffen up the action. An old pair of inner valve springs from a Triumph or BSA are just the right size and can he had from nearly any bike shop. We had trouble with the forks bottoming on high jumps and tried the auxiliary springs hut got better results by switching to 30 weight oil. This will he strictly a matter of individ ual preference.

Ussa and I flad tflree mectianical failures during the more than 100 motos which made U~ our 37 races. One of those occurred when the spark plug cap worked its way loose and fell off. It was then replaced with an accessory cap. Sparky or Lodge caps are completely waterproof and fit very snugly. l'he new I 971 Stilettos now come with a Sparky cap as standard equipment.

An extra spark plug was fitted in the drilled and tapped hole in the head. A compression release could have been installed hut the latest trend in motocross is to get away from them. Serious riders feel they are used as crutches and hinder learning of the proper braking procedures. If you over-use them, they may slow you up too much.

We grooved our brake shoes as shown in the photograph. This is not a neces sity hut helps to keep mud and dust off the braking surface. It is easily done with a hand file.

The front brake cable was taped to the left fork leg just below the rubber fork hoot. It had a tendency to jump free of its stop during a race and leave the rider with just the back brake for stopping power.

Other Stiletto riders say that the rear sprocket bolts are an absolutely critical item. They must be safety wired and fastened with locking tabs. Those six bolts are prone to loosening and when they come loose they tend to snap off. sometimes damaging the rear hub.

The conical lock washers on the engine mounting bolts were ineffective and allowed the engine mounts to come loose repeatedly until they were re placed with conventional lock washers. Excessive engine vibration signaled it was time to tighten up the mounts again. Loose swinging arm bolts will also cause the engine to vibrate.

We were dissatisfied with the steering travel, or lock, if you prefer, found on the Stiletto, hot h for racing arid maneu vering the hike around the garage. The remedy was to hacksaw ahout a quart er-i rich of metal from the Steering stops. The Iront fender was removed to enable the operation.

The exhaust pipe collar which screws into the cylinder barrel continually came loose, breaking its safety wire, until it finally stripped the threads out of the barrel and began letting exhaust gases leak. I had a machine shop make a new collar out of aluminum so it could he welded to the barrel. A small spring could have been hooked in the collar and then attached to the frame with a loop of wire to prevent the collar's loosening.

When all the above was completed. the Ossa was ready to race and we could reasonably hope to finish. The rest of this information was compiled during the racing campaign from our experi ence and that of other Ossa owners who volunteered their hard-earned hints and tips. They told us the problems they had had, and gave us a hint of what we should look out for.

The IRZ carburetor has a few weak nesses. If you do much fine tuning of the mixture and change the needle heights, (there are two needles), replace the needle clips with new ones each time you remove them. They are subject to working loose all by themselves and falling through a hole in the top of the slide. (`onsequently, they are promptly sucked into the cylinder and cause sei zure, or piston and cylinder wall dam age. Ama! clips can be sul)stituted if their ends are clipped off slightly to fit.

Just like in the Amal Monobloc, the IRZ's float level is subject to change from the landing impacts of going over jumps, so it must lie checked periodically. Adjust the float level so the tickler just barely pushes on the float, this is for motocross racing only; the sustained higher rpm's of I I racing call for a higher float setting to avoid fuel starvat ion.

The float bowl cover may sometimes prove difficult to replace without leaks. Use the fiber gaskets only, not the rubber ones, and tighten both bolts evenly. Replace the O-rings under the bolt heads when they become chewed up. and safety wire the bolts to prevent t hem from coming out.

The Ossa's fuel petcocks are poorly designed and may permit fuel to weep into the float chamber when they have been in use for some time. If they get too bad. you may have to pull the fuel lines oil between races to assure easy starting. At day’s end. it doesn't hurt to run the engine with the taps closed, which will help prevent engine-off siphoning.

Seals on the Betor l orks don't last too long in some cases. When they begin to leak and an oil residue shows up on your fork tubes, replace the seals with Honda front fork seals of the right size. The Honda seals tit Betor and Ceriani forks and do a better job than the originals. Don't throw out the old seals but install them upside down on the fork tubes above the circlip and under the rubber boot. This acts as a doubly effective barrier against mud and grit and your forks will go much longer without attent ion.

Many riders fee! cable-operated brakes are not as positive feeling as rod-operated brakes, so the Ossa's rear brake system must be kept in top shape to get the maximum effectiveness from it. The cable should be greased regularly at its grease fitting. Don't stop greasing when grease comes out of the cable at the wheel end. but wrap something around the housing to force the grease along the cable's entire length. It this doesn't work, remove the cable and soak it in oil. Check it periodically by unhooking the cable at its brake end and moving it back and forth to make sure there is absolutely no drag.

The Ossa's front hubs are a weak point, as they are with several other brands of motocrosser. The strains of motocross often prove too much and they crack around the spoke holes. Many riders ignore the cracks and continue racing with no adverse effects. Welding the cracks has worked in some cases but the only permanent and sure cure seems to be fitting a wheel and hub assembly from another machine, (»reeves and Husqvarna hubs are relatively easy to install, hold up better, and reduce that critical unsprung weight. 1 fitted a Husky hub with a minimum of machine work, just drilling out the fork tube clamps to accept a larger axle and bending a backing plate strap from a Bultaco Pursang to fit. The backing plate had to be drilled for two holes to mount the strap. Weight saved; 5 lb.

Akront alloy rims found on the Ossa and many other racing and trail bikes have a tendency to crack and break at the weld, which is located under the Akront sticker. They can easily be repaired by heli-arcing. Be sure your welder grinds a groove all the way around the crack so the weld becomes a part of the rim. Our rear wheel cracked very early in the game but has held up perfectly since the repair, even surviving two laps of racing on a flat tire.

Spoke tension must be checked constantly. even between motos if necessary. Use a spoke wrench to avoid rounding off the soft nipples and tighten each spoke a fraction of a turn, going around the wheel as many times as necessary. It's a time consuming job. but must be done right.

Whenever you remove either wheel, be very careful about cleaning the axles before they are reinstalled. Coat them and the felt washers which fit next to the brake drums with grease to permit easy reassembly and to keep water out of the drums.

(Continued on page 144)

w w w - -Continued from page 101

Watch your chain tension. The Spanish chain on our bike stretched continuously during its life, requiring frequent adjustment. And, it also kinks. If you can find a prestretched English racing chain in your vicinity, it should be one of your first substitutions.

If your rear fender and tailpiece starts to shake too much, look for a broken mount. The tubing which mounts the tailpiece often breaks free of the frame and must be rewelded.

An occasional Ossa breaks its clutch hub rivets. Fortunately there is enough room in the clutch assembly for hardened bolts and nuts to replace the rivets. If you should break more than one primary chain, look for a soft cush-drive spring. We had trouble in neither area here.

The stock handlebars are too soft. They will usually bend with each fall and are best replaced with accessory bars. We got a set of Bates bars, part number 8333, nearly identical to the stock configuration, which have worked very well.

The Stiletto's footpegs are among the best around for gripping your boot soles in muddy going, but have one small drawback. They may stick in the up position if you go over a jump with one foot off a peg. Springs could be installed but a simpler solution is to tighten the pivot bolt until the pegs are no longer free to flop up and down. A slight bit of tension will hold them in place and at the same time permit them to give if you hit something.

However, there is another approach to the footpeg problem, which must be given credence because such riders as Bugsy Mann swear by it. This is to make the peg flop as loosely as possible so that it bounces back, even without a return spring. This is accomplished by inserting a bushing or washer so that tightening will not cause the peg to bind. One advantage to this idea is that the peg will not bind in the folded position, as would a tightened one.

The gear change shaft is such a close fit where it comes through the primary case cover that it may occasionally stick if dirt or mud works its way in along the shaft. This will cause hard, if not impossible shifting, and gives the appearance of serious transmission problems when the trouble is something much simpler.

Remove the primary case cover, tapping on the shift shaft with a mallet, and clean out the mud or dirt. If this occurs more than once, you may wish to drill the hole out a little larger. Remove the oil seal on the inside to prevent damage to it and drill the hole out with a 31/64-in. drill bit. Keep the felt washer on the outside of the case well soaked with oil and you should avoid any future problems.

The shift shafts may be too soft for the job. We have seen several Stilettos get bent shafts from collision damage in racing. The cases have to be split to replace the shaft so try straightening before you shell out the approximately $60 it will cost to have the shaft replaced. A friend bent his twice in a matter of a month’s racing so he came up with a simple straightening tool that should work in a majority of cases. He cut off the portion of a gear change lever that contains the splines. He welded this round piece inside a twofoot length of pipe and had a wonderful piece of money-saving apparatus.

You will need a few tools not found in the ordinary toolbox to take adequate care of your Stiletto. Buy a set of Metric Allen wrenches plus oversized open-end wrenches of 23 and 25 millimeters for the axle bolts and fork caps.

Of the special tools made solely for Ossas, you may wish to acquire a flywheel puller so the timing can be changed if necessary. The puller costs $6.95. A full line of special tools to completely strip the engine is available from your dealer.

Parts costs are in line with the other Spanish bikes and we have found availability to range from good to excellent. The Stiletto carries no warranty as such, because it is a competition machine, but Yankee will replace items found defective within a reasonable period of time. They have a good reputation along this line.

The strains of motocross are enormous. Swedish physiologists say motocross makes demands on the human heart and body that are not even approached by any other sport.

The same applies to the machines used. Any machine raced nearly twice a week for six months would rack up a similar list of changes and improvements needed. If you have been considering the purchase of a Stiletto, don’t be put off by this list. In the more than 100 separate motos we raced, there were only three mechanical tailures that put us out of the running. We had a broken front hub, an errant spark plug cap, and a thrown chain. There were no engine, transmission or clutch problems whatsoever. That is a fine record of reliability.

Properly set up and maintained, and in the right hands, the Stiletto is definitely a motocross winner.

View Full Issue

View Full Issue