THE SERVICE DEPARTMENT

TO COMPRESS OR NOT

JODY NICHOLAS

I have some questions that I hope you can and will answer. 1) Does the high compression ratio of the engines of Ossa, Maico, Bultaco, Greeves, etc., cause extra stress which would wear the motor out more quickly than the lower compression of Yamaha, Suzuki, Kawasaki, etc?

2) Is a two-cycle as durable as a Four?

3) Motorcycle distributors have information on the maximum torque and horsepower but not on the range. Is there anywhere I could get a graph (or listing) of horsepower/rpm and torque?

Gary B. Zimmerman Athens, Ga.

The compression ratios on the Bultaco, Ossa, Maico, etc. are measured from the bottom of the stroke and do not take into account the all-important location of the top of the exhaust port. Most Japanese manufacturers measure the compression ratio of their machines from the top of the exhaust port, which does not allow the full stroke of the engine to be used for the computation. This is a much more realistic figure than the higher ones found in some brochures.

Measured from the top of the exhaust port, most compression ratios on two-cycle engines intended for a specific use such as motocross, or even a road machine, are very close to others in their use group.

A two-cycle engine can be just as durable as a four-cycle engine, and has the advantage of having fewer moving parts to wear out. Many good two-cycle machines are available, and several fourstrokes are also to be had at similar prices.

The manufacturers have access to all the performance figures of their respective engines, but very seldom publish these figures in graph form. Try writing to the manufacturer in question. Perhaps they will have the information available.

YAMAHA BACKFIRE

I own a 196 7 250 Yamaha Catalina with electric start and spark advance. Ever since I bought it, it’s had a lag at 6000 rpm. I seized it, and then had the engine completely rebuilt. The lag is still there. I put larger jets in the carburetors and tried the timing and gap settings at every possible interval. The lag persists.

(Continued on page 16)

Continued from page 14

It backfires through the carburetors at about 6000 rpm, but at lower and higher speeds it goes very good. Any suggestions?

Don Moyer Fenwick, Ontario, Canada

It sounds as if the float levels in the carburetors are not correctly adjusted. At a certain point in every engine’s rpm range, there will be more vibration than at other speeds. It is conceivable that your float levels are set too high, creating an overly lean condition. At 6000 rpm, it is likely that the vibration causes the fuel remaining in the float chambers to froth, thereby adding to the problem of supplying the engine with adequate fuel. Merely going to a larger size jet under such conditions would not necessarily riehen the mixture enough to prevent seizure.

Changing the point settings is a dangerous move unless you are certain that the ignition is still within the tolerances recommended by the manufacturer. Two-cycle engines are particularly sensitive to even slight changes in ignition timing, and being just 0.5mm off the recommended setting can cause engine failure from overheating. Your Yamaha dealer can check the float levels and time the engine for a nominal fee.

RELUCTANT KAWASAKI REVISITED

/ am writing in regard to “Reluctant Kawasaki” (Service Dept., April ’70). A 1969 A-7 Kawasaki with C.D.I. should have no problems in starting, idling or slow running, even in cold weather, using Champion UL19V surface-gap spark plugs.

It appears to me the motorcycle in question may have a defective system as the early ones were known to have problems. However, before jumping to conclusions, I would suggest bringing the magnetic pickups at the signal generator as close as possible to the rotor.

Two are used on the “A” series and one on the “H” series. Lowering the oil pump cable all the way will decrease oil consumption and smoke without any harm to the engine.

A. Aharonian Kawasaki Ltd. W. Chester, Pa.

Many thanks for the tip, Andy. We’ll print it in hopes of saving a few owners from despair.

(Continued on page 18)

Continued from page 16

USE THE PROPER OIL

I have a Honda CB77 (Super Hawk) motorcycle that I recently had completely overhauled. This motorcycle had just slightly over 10,000 easy miles on it with 8000 miles using Quaker State motor oil, most of this the 30W-HD oil, but I switched to the 10W-30 Super Blend last fall. Also, I use Amoco (non-leaded) gasoline in it.

The overhaul was made because the engine suddenly developed a loud roaring or whining noise. It was not using any oil at all between the 1000-mile changes, which were made regularly.

The Honda dealer who did this work replaced pistons and rings, one main bearing and all of the camshaft bearings. The pistons had been rubbing the cylinder walls, although the pistons and rings were free and clean of carbon. On the undersides of the pistons there was a rust-colored, powdery film that rubbed off when touched. Otherwise the engine was very clean inside.

The dealer said the motor oil was responsible for the trouble and that I should change to an oil recommended for motorcycles. I also have a new Honda CB450 in which I started using Quaker State 10W-40 Deluxe motor oil. Do you think this oil is good enough for these bikes?

Johnnie Williams New Bern, N.C.

Honda recommends any premium multi-viscosity motor oil intended for MS, DG, and DM (API Service Classification) service in their machines, and I feel certain that Quaker State HD-30 and 10W-30 Super Blend both fall into at least one of these categories. It is common knowledge that air-cooled engines operate at higher temperatures than water-cooled engines. This places a greater burden on the oil while it is performing its primary functions, namely, lubricating, cooling, cleaning and protecting an engine. As engine heat increases, lower quality oils have a tendency to break down molecularly and rob the engine of its required protection and lubrication.

A number of well respected automobile manufacturers, including Porsche, recommend single-viscosity oils in their cars, maintaining that a singleviscosity oil is more stable and less likely to break down under high temperatures and stress than the multi-viscosity varieties. I personally recommend using a single-weight “racing oil” such as those marketed by Kendall, Valvoline, Quaker State, Pennzoil and a number of other companies, and changing it at least as frequently as recommended under normal riding conditions, and even more frequently if the machine is not ridden often or in cold weather. There is a little more expense in buying the racing variety oils and in changing the oil often, but engine life can be substantially increased. It’s also good for one’s peace of mind!

STREET RELEASE

Through my experience with twostroke dirt machines, 1 have come to know and love the compression release. Now I find myself in possession of a Kawasaki Mach III, no dirt bike but a two-stroke, and, it seems to me, a good place for three little release valves to find a happy home. I realize releasing road two-strokes is not a common practice, though I’m not sure I understand why, unless the CHP feels that the added safety of the release as a braking device doesn’t justify the noise they make. Anyway, here are my questions:

Does anyone make an appropriate three-way junction cable assembly, or will it be necessary to adapt a Kawasaki Avenger throttle cable assembly?

Please explain the difference in the types of releases: one-way, two-way, filtered, nonfiltered. It would seem that a one-way release would give the best braking and would not require a filter since it would exhale only, so why hasn `t this type gained wider accep tance? I would like to avoid large external filters if possible.

Will the release valve affect combustion chamber tuning? Will the necessary fin removal cause heating problems in that critical middle cylinder?

Dwane Goodell FPG San Francisco, Calif.

As you say, fitting compression releases to road motorcycles isn’t a common practice, and it really is quite unnecessary. Even road racing twostrokes rely on their wheel brakes, as engine braking is only very slight.

It would be possible to install one compression release in each cylinder head if you must, but the work would be considerable and costly.

First, you would have to have an area heli-arced in each head, which would then have to be drilled and tapped for a 14-mm compression release. This would also involve cutting away a few fins, which would hamper cooling somewhat, especially on the middle cylinder. As far as I know, there are no three-way junction boxes available, although one could be fabricated quite easily.

A one-way release is designed to open only on the compression stroke, thereby eliminating any outside air (which could contain dirt) from being sucked into the engine. A two-way release, which is open all the time when actuated, draws in outside air and dirt. Filters are available for these from several manufacturers. However, besides having to be cleaned periodically, they further restrict the flow of cooling air around the critical combustion chamber area.

Properly installed, a compression release won’t alter the combustion chamber shape, but welding and machine work of this precision is expensive.

Last, but surely not least, is the noise problem that is always encountered when fitting a compression release. The Mach III surely would be transformed into a shrieking banshee when the releases were actuated, and you would not incur any good favor from the local gendarmerie. The only way to eliminate the noise problem would be to install releases that vent back into the exhaust header pipes, but, aside from not working quite as well as a conventional release because of pressure differences between the spent exhaust gasses already in the pipe and the charge from the release, they would create an unsightly conglomeration of external plumbing which would detract from the machine’s handsome appearance.

THUNDERBOLT TUNING

I purchased a new 1969 BSA Thun derbolt (650 single carburetor). I put reverse megaphones on it, but it does not "turn on" like my 1965 Triumph Trophy, also a 650 single-carh. The BSA does not seem to come on the pipes with as much gusto, and it comes on later-at 3500 rpm instead of 3000 rpm like the Triumph. I would like to remedy this without sacrificing reliability.

(Continued on page 20)

Continued from page 19

Could it be that the crossover pipe on the BSA keeps the cones from working the exhaust gasses effectively ? I think it runs too rich even with cones, but I don’t know what jet to go to without burning valves. Would changing the slide cut on the carburetor help? Would enlarging the hole at the end of the cones help? The needle is all the way lowered for leanness.

I would like it to “come on” more violently at a lower rpm by making simple changes in the carburetor and/or the exhaust system.

William W. Adams Powell, Ohio

The connecting exhaust pipes on your machine were designed to aid in scavenging the burned gases from the cylinders, and, as a bonus, the low-end torque improved somewhat from the earlier models with two single exhaust pipes. When changing to a megaphonetype exhaust on your machine, it is a good idea to go up at least two jet sizes initially, run the machine wide open on the road for a short distance, and shut the engine off without allowing it to idle. The spark plugs must then be checked for a light-brown color on the porcelain around the center electrode. If the porcelain is whitish in color, you are still too lean; if it is a sooty black, you are too rich. It shouldn’t be necessary to alter the needle position from the third notch, and the 3xh cutaway slide should prove satisfactory.

Enlarging the opening of the cones usually has the effect of moving the power “cone-in point” farther up the rpm scale, and consequently acceleration deteriorates below that point. By enlarging the cones too much, you can decrease the torque to that of a mild 250-cc bike!

The cams in your BSA are somewhat wilder in design than the cams in your Triumph. Theoretically, the BSA should develop more power at the top end, while suffering a slight lack in the lower midrange, where the Triumph shines.

For the best all-around performance and a substantial' increase in midrange power, the stock mufflers should be put back on and the tuning instructions in your rider’s manual followed scrupulously. You will probably find that your bike will be faster through the speed ranges, and will assuredly be less offending to the public and the law!

(Continued on page 22)

Continued from page 20

PLUG PROBLEM

I have a 1969 Yamaha AT-1 125-cc Enduro, and have been having a few problems Keeping it in spark plugs. I recently took the Autolube system off and have been mixing the gas and oil at a 20:1 ratio, but the problem still exists.

As long as I ride the bike at fairly low engine speeds, I don’t have any trouble, but when I go to the desert where I climb long sand hills, I can only run for a few minutes at full throttle before the machine starts backfiring and stops. When I pull out the plug, I find a piece of carbon between the electrodes, and as soon as I knock it out, the bike runs just as before.

I’m presently using NGK B-8 and B-9 series plugs, and have tried several different brands of two-cycle oil, but the problem still occurs. Can you suggest anything?

Fred J. Schwartz San Diego, Calif

There are a number of things that could cause a problem with spark plugs such as yours. The NGK spark plugs you are using are both in the ballpark regarding the heat range, and it is unlikely that a colder plug would help matters any.

Some oils leave a deposit which is metallic in appearance, and tend to foul spark plugs rapidly, but since you’ve tried several different brands of oil, your problem probably isn’t with the oil itself.

You should begin by making certain that you aren’t passing dirt and sand into the engine because of a split air filter or other leak in the inlet system. One grain of sand can combine with the oil in the fuel/air mixture and lodge itself between the spark plug electrodes, causing your problem.

It is also important that you have a main jet that is large enough. Most of the desert areas in the San Diego area are near sea level, which would require a larger than standard main jet.

Also make certain that the ignition timing is properly set. If it is too far advanced, your machine will tend to detonate or “ping,” and if it is too far retarded it will run hot, possibly causing a piston seizure.

It has been my experience that twocycle engines of the Yamaha’s variety perform satisfactorily using regular pump gasoline. Because of its lower content of tetraethyl lead than “hightest” gas, there is less possibility of fouling or “B-B-ing” a spark plug.

Another trick you might try is to widen the gap between the electrodes to about .030 in. Your machine might be a little more difficult to start, but carbon particles won’t form as readily between the electrodes.

View Full Issue

View Full Issue

More From This Issue

-

Departments

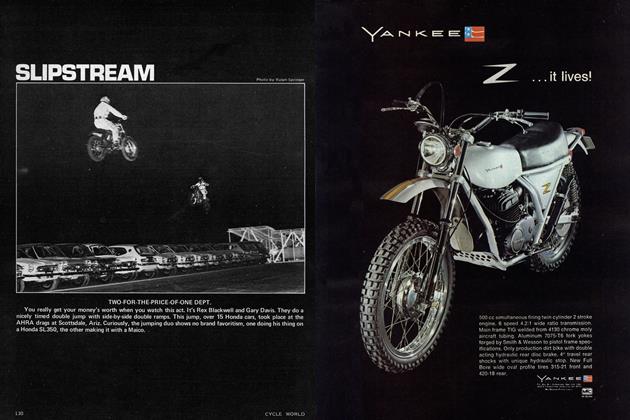

DepartmentsRound Up

JULY 1970 By Joe Parkhurst -

Letters

LettersLetters

JULY 1970 -

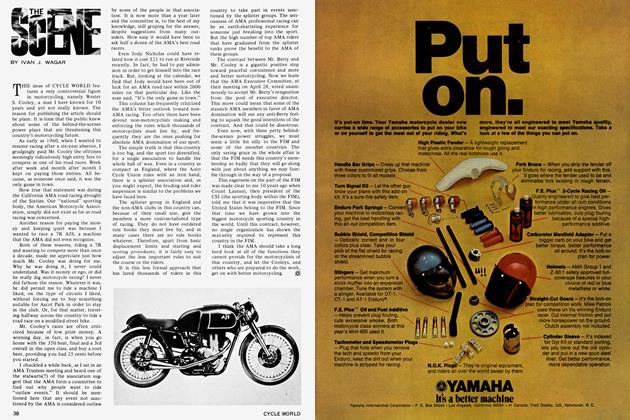

Departments

DepartmentsThe Scene

JULY 1970 By Ivan J. Wagar -

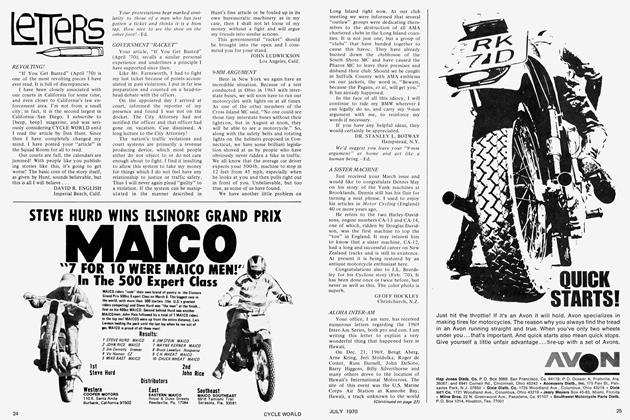

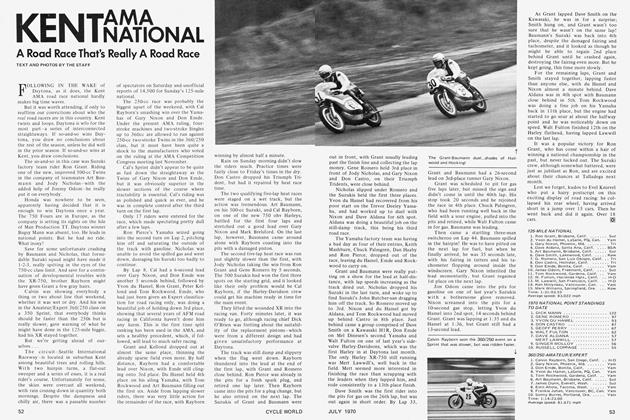

Competition

CompetitionKent Ama National

JULY 1970 By The Staff -

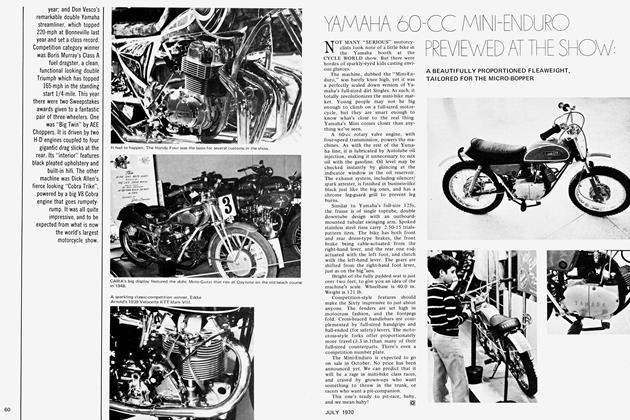

Special Features

Special Features1970 Cycle World Show

JULY 1970 -

Road Tests And Impressions

Road Tests And ImpressionsYamaha 60-Cc Mini-Enduro Previewed At the Show:

JULY 1970