SERVICE

Metric fasteners

I own six motorcycles, and do my own maintenance and modifications. That brings up my problem: Where do you obtain metric fasteners in bulk? I cannot seem to find some types of fasteners in metric sizes at all—things like “Rivnuts,” thumb screws, cap nuts and castle nuts (although my dealer will order the latter if I give him the size and wait two weeks). Any ideas?

Terry Beaudry Campbell, California

Metric fasteners of all types aren V that hard to find; try checking a business-to-business yellow pages under fasteners—industrial. There should be several suppliers in your area from whom you can obtain most metric nuts and bolts.

We can recommend two mail order sources as well. Metric Screw & Tool Co. (9 Lake Street, Wakefield, MA 01880; [617] 245-4950) puts out a catalog targeted directly at motorcyclists, and will ship small orders C.O.D. The second. Metric & Multistandard Components Corp., has an enormous selection of metric and Whitworth fasteners, including “Rivnut " style combination-rivets-

thread-inserts, all featured in a 300plus-page catalog. Metric & Multistandard has three different warehouses across the country. There's one at 120 Old Saw Mill River Road, Hawthorne, New York 10532; (914) 769-5020. Another is at 409 Heathrow Court, Burr Ridge, Illinois 60521; (312) 655-9009. And the third is at > 9840 Monroe Drive, Dallas, Texas 75220; (214) 358-4106. Any of these warehouses will accept phone orders, but minimum quantity for small fasteners is usually a hundred of each.

CONTINUED

More on rain grooves

The April Service column’s response to Steve Conti’s query about riding rain grooves without the constant feeling of dumping the bike was correct, but some additional explanation seems appropriate.

On many roads, the grooves are cut in swaths about 18 inches across. Where the swaths join, the steering effect is worst, and most unfortunately, this is often in the line an experienced biker would prefer to follow on an ungrooved road. Move over. The steering effect will be reduced, but not eliminated.

What now?

If the grooves frighten you, chances are that you’re hanging on to the bars with a death grip, trying to compensate for the steering effect. This is the worst thing you can do, because this tight coupling of musculature into the steering system magnifies the pendulum effect, increasing any wobble. Instead, relax your grip slightly and allow the grooves to steer the bike. It will wander slightly and randomly from side to side, but the path will average out to a straight line. On a light machine such as the BMW, it is also extremely important to keep the steering head bearings correctly adjusted and not to overload the rear end with luggage. It also helps to slide forward on the seat and to hunch over the bars (for a more forward weight distribution), and to keep your speed over 50 mph.

Everything above applies in spades to bridges with exposed steel gratings. However, when these are wet, the grids are as slick as ice, especially at the center of the lane where an oil film collects. For that situation, act as you would on ice: Keep a steady pace, don’t use your front brake, and pray.

Ed Fairstein

Oak Ridge, Tennessee

Members of the Cycle World staff have had experience on bridges with exposed, steel-grated surfaces (including one in Boston that has a curve in it as well), and we'd make a single recommendation for dealing with this> type of surface in the rain: don 7. Rubber on wet steel offers extremely low traction, and a short detour around a steel-grated bridge in the rain seems entirely reasonable.

CONTINUED

Gearing theory

I own a 1984 750 Interceptor. I would like to change the final gearing to slow the engine speed down at any given road speed. A Honda Sabre spins 4100 rpm at 60 mph and the VF750 is at 4700 rpm at the same speed. Because the Interceptor has more power and torque, I shouldn’t have any trouble dropping its engine speed at 60 mph by 500 rpm.

My question is, what sprocket sizes should I use to achieve this drop in engine speed?

Scott Golden

Garden Grove, California

Honda VF750Fs came with 44 rear/17 front sprockets, for a 2.588-to1-final drive ratio. To drop engine speed by 500 rpm, to roughly 89 percent of the current speed at 60, you have to change the final-drive ratio by a similar percentage. That requires a final-drive ratio of about 2.32 to l, which could be roughly achieved by a 19-tooth front sprocket combined with the 44-tooth rear (44/19 — 2.316), or by the stock 17-tooth rear sprocket combined with a 39-tooth rear sprocket (39/17=2.294). The first option would drop engine speed from 4700 rpm at 60 mph in top gear to 4205 rpm; the second would decrease engine speed to 4166 rpm. The larger front sprocket option would reduce loads on the chain, extending its life, but, unfortunately, the Interceptor might not have enough room for a 19tooth front sprocket. If an 18-tooth sprocket will fit, a 42/18 combination would give a ratio of2.333 and an engine speed of4237 rpm at 60, and would be the best compromise.

Your dealer should be able to order sprockets for you from several different sources, including Circle Industries, Rocky Cycle and PBI (1550 S.E. 102nd, PO. Box 375, Clackamas, OR 97105; [503] 655-5128). H

View Full Issue

View Full Issue

More From This Issue

-

Editorial

EditorialCountering the Steering Myths

June 1985 By Pauldean -

At Large

At LargeInside the Accidental Fortress

June 1985 By Steven L. Thompson -

Letters

LettersLetters

June 1985 -

Rounup

RounupLand Closure: the Fight For the Open Range

June 1985 By David Edwards -

Roundup

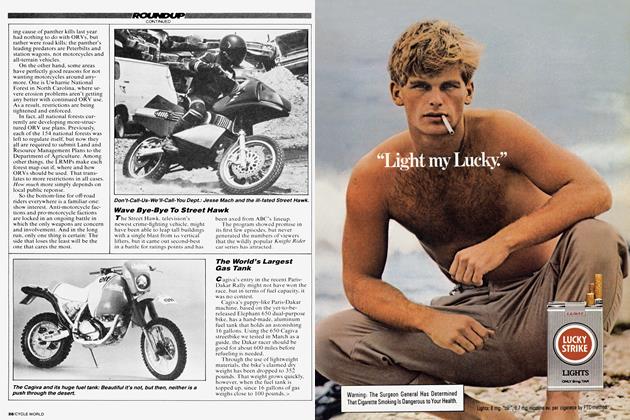

RoundupWave Bye-Bye To Street Hawk

June 1985 -

Roundup

RoundupThe World's Largest Gas Tank

June 1985