An Airhorn For Soft-Spoken Machines

If You Want To Improve Upon The Standard Product, All the Parts You Need Are In The Mail-Order Books.

A.F. BISSELL

THE GREATEST uncontrolled hazard to the careful motorcycle rider is the truck or automobile driver who seems, more often than not, blind to the presence of bikes on the highway.

At night, good headlights are effective signalers, but during the daytime most bike riders have no effective signals to warn of their approach. Even booming, unmuffled engines get ignored by closed cars and noisy trucks.

How about a good horn? There are darn few supplied as standard equipment for motorbikes that deserve the name, and the ones supplied as accessories are only fairly effective. Nor can you expect a standard automobile horn to work with the majority of motorcycle batteries.

Some years ago, a resourceful fellow added a few more pounds to the tail of his big Harley in the form of a massive air compressor to drive a couple of very strong air horns. It was a major engineering feat, but it worked. Today you can obtain very compact, reasonably priced, electric air horns from many local and mail order sources. These are easy to mount, provide a pleasant and effective blast, and make a dressy accessory that could save your life. Even aerosol can units can be used, although they are somewhat inconvenient in operation.

A $17 electric set from the Montgomery Ward catalog proved the answer for me in many miles of rough and smooth, cold and hot, city and country, wet and dry terrain. On an older, 6-volt system British Twin, the electrical wiring is a cinch and appears adequate. The newer 12-volt systems would be even better because of less wiring and contact resistance loss, and the better efficiency inherent in the 12-volt compressor. At any rate, the 20 ampere/ hour 6-volt battery system in many of the larger cycles is adequate to drive the low-cost dual Italian sports car air horns effectively.

Problems involved in installing these include: secure mounting of the compressor in a vertical position, need for minimum length of air hose to reduce response time and increase sound level, need for low resistance wiring and ground return, mounting of trumpets with slightly downward tilt, and the mounting of the compressor controlling relay.

It is assumed that no one would care to use a selector switch, supplied with some air horn sets, to allow switching between the standard and the good horns.

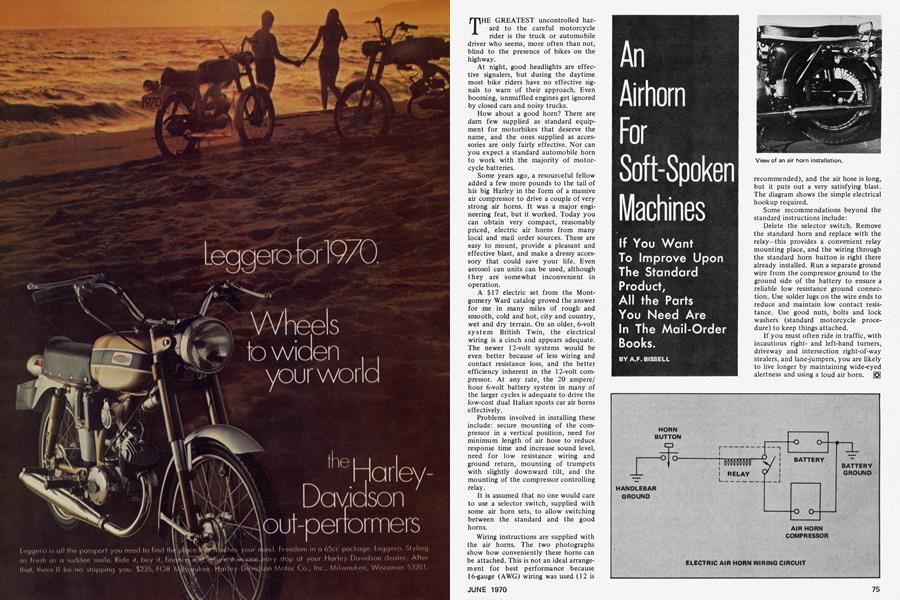

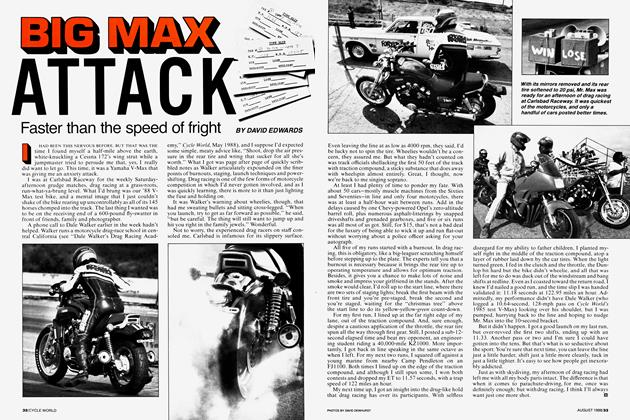

Wiring instructions are supplied with the air horns. The two photographs show how conveniently these horns can be attached. This is not an ideal arrangement for best performance because 16-gauge (AWG) wiring was used (12 is recommended), and the air hose is long, but it puts out a very satisfying blast. The diagram shows the simple electrical hookup required.

Some recommendations beyond the standard instructions include:

Delete the selector switch. Remove the standard horn and replace with the relay—this provides a convenient relay mounting place, and the wiring through the standard horn button is right there already installed. Run a separate ground wire from the compressor ground to the ground side of the battery to ensure a rehable low resistance ground connection. Use solder lugs on the wire ends to reduce and maintain low contact resistance. Use good nuts, bolts and lock washers (standard motorcycle procedure) to keep things attached.

If you must often ride in traffic, with incautious rightand left-hand turners, driveway and intersection right-of-way stealers, and lane-jumpers, you are likely to live longer by maintaining wide-eyed alertness and using a loud air horn.

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsRound Up

JUNE 1970 By Joe Parkhurst -

Legislation Forum

Legislation ForumIllinois Success Story

JUNE 1970 By Lee Strobel -

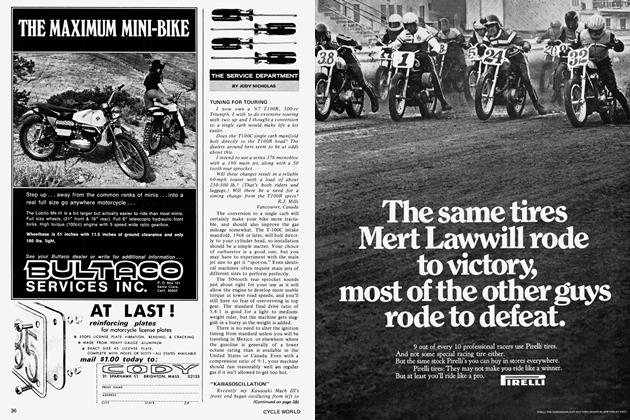

Departments

DepartmentsThe Service Department

JUNE 1970 By Jody Nicholas -

Departments

DepartmentsThe Scene

JUNE 1970 By Ivan J. Wagar -

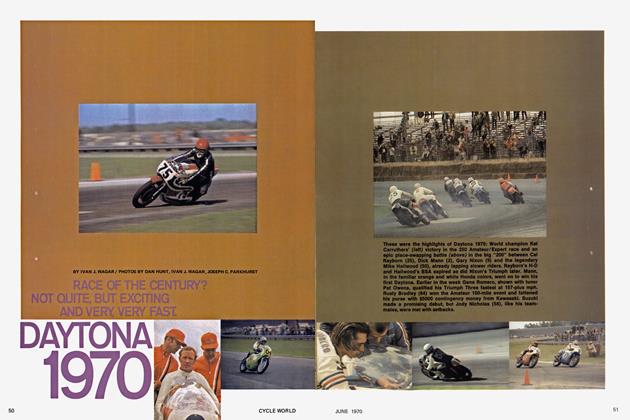

Special Competition Feature

Special Competition FeatureDaytona 1970

JUNE 1970 By Ivan J. Wagar -

Features

FeaturesOverland Adventure

JUNE 1970 By Dean Haagenson