THE BOLGER TOUCH

Joe’s Bultaco Went Through A Weight-Watchers’ Course That Is An Invaluable Lesson For Owners Of Dirt Bikes Everywhere

DAN HUNT

PRODUCTION MACHINES for dirt racing and trailing have reached a high plateau of excellence in recent years. Buy the one to match your tastes and chances are you will not have to modify it greatly to get it to handle and perform properly.

But perfection? There is no such thing. No matter how good the machine is, it may be made better.

One man who has a knack for making things better is Joe Bolger. He needs no introduction to New England scrambles riders. He is a living legend there, after more than a decade of racing. Racers come and go and “hang it up,” but Bolger, a “Marlboro Country” sort of man, with distinguished but natural looking grey hair to match, is still out there, doing it. He’s the epitome of the Sportsman dirt racer. He does it because he loves it. Even when he gets paid.

He is still a top contender in the New England scrambles scene, and last year captained the winning U.S. team in the Grafton/Copetown series.

Joe has a shop in Holden, Mass., where he handles Honda, Kawasaki and Bultaco. He is in charge of service and so holds forth in his basement workshop. In a day of wrangling with bikes, customers and kibitzers (who sometimes stand 15 or 20 deep, hoping perhaps to pick up some of his Irish Canadian craftiness and charm by osmosis), he also manages to spend time on “developmental” work. The sum works out to an 11-hour day, through which he remains pleasant, and manages to keep a straight face, bordering on a put-on, when confronted by the most outlandish conversation.

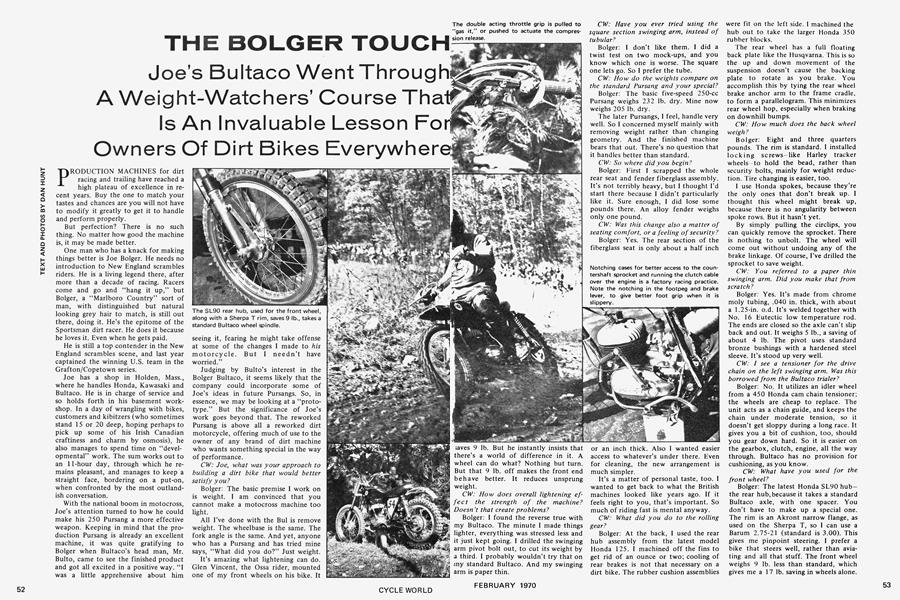

With the national boom in motocross, Joe’s attention turned to how he could make his 250 Pursang a more effective weapon. Keeping in mind that the production Pursang is already an excellent machine, it was quite gratifying to Bolger when Bultaco’s head man, Mr. Bulto, came to see the finished product and got all excited in a positive way. “I was a little apprehensive about him seeing it, fearing he might take offense at some of the changes I made to his motorcycle. But I needn’t have worried.”

Judging by Bulto’s interest in the Bolger Bultaco, it seems likely that the company could incorporate some of Joe’s ideas in future Pursangs. So, in essence, we may be looking at a “prototype.” But the significance of Joe’s work goes beyond that. The reworked Pursang is above all a reworked dirt motorcycle, offering much of use to the owner of any brand of dirt machine who wants something special in the way of performance.

CW: Joe, what was your approach to building a dirt bike that would better satisfy you?

Bolger: The basic premise I work on is weight. I am convinced that you cannot make a motocross machine too light.

All I’ve done with the Bui is remove weight. The wheelbase is the same. The fork angle is the same. And yet, anyone who has a Pursang and has tried mine says, “What did you do?” Just weight.

It’s amazing what lightening can do. Glen Vincent, the Ossa rider, mounted one of my front wheels on his bike. It saves 9 lb. But he instantly insists that there’s a world of difference in it. A wheel can do what? Nothing but turn. But that 9 lb. off makes the front end behave better. It reduces unsprung weight.

CW: How does overall lightening effect the strength of the machine? Doesn’t that create problems?

Bolger: I found the reverse true with my Bultaco. The minute I made things lighter, everything was stressed less and it just kept going. I drilled the swinging arm pivot bolt out, to cut its weight by a third. I probably wouldn’t try that on my standard Bultaco. And my swinging arm is paper thin.

CW: Have you ever tried using the square section swinging arm, instead of tubular?

Bolger: I don’t like them. I did a twist test on two mock-ups, and you know which one is worse. The square one lets go. So I prefer the tube.

CW: How do the weights compare on the standard Pursang and your special?

Bolger: The basic five-speed 250-cc Pursang weighs 232 lb. dry. Mine now weighs 205 lb. dry.

The later Pursangs, I feel, handle very well. So I concerned myself mainly with removing weight rather than changing geometry. And the finished machine bears that out. There’s no question that it handles better than standard.

CW: So where did you begin?

Bolger: First I scrapped the whole rear seat and fender fiberglass assembly. It’s not terribly heavy, but I thought I’d start there because I didn’t particularly like it. Sure enough, I did lose some pounds there. An alloy fender weighs only one pound.

CW: Was this change also a matter of seating comfort, or a feeling of security?

Bolger: Yes. The rear section of the fiberglass seat is only about a half inch

or an inch thick. Also I wanted easier access to whatever’s under there. Even for cleaning, the new arrangement is much simpler.

It’s a matter of personal taste, too. I wanted to get back to what the British machines looked like years ago. If it feels right to you, that’s important. So much of riding fast is mental anyway.

CW: What did you do to the rolling gear?

Bolger: At the back, I used the rear hub assembly from the latest model Honda 125. I machined off the fins to get rid of an ounce or two; cooling of rear brakes is not that necessary on a dirt bike. The rubber cushion assemblies were fit on the left side. 1 machined the hub out to take the larger Honda 350 rubber blocks.

The rear wheel has a full floating back plate like the Husqvarna. This is so the up and down movement of the suspension doesn’t cause the backing plate to rotate as you brake. You accomplish this by tying the rear wheel brake anchor arm to the frame cradle, to form a parallelogram. This minimizes rear wheel hop, especially when braking on downhill bumps.

CW: How much does the back wheel weigh ?

Bolger: Eight and three quarters

pounds. The rim is standard. I installed locking screws-like Harley tracker wheels to hold the bead, rather than security bolts, mainly for weight reduction. Fire changing is easier, too.

I use Honda spokes, because they’re the only ones that don’t break up. 1 thought this wheel might break up, because there is no angularity between spoke rows. But it hasn’t yet.

By simply pulling the circlips, you can quickly remove the sprocket. There is nothing to unbolt. The wheel will come out without undoing any of the brake linkage. Of course, I’ve drilled the sprocket to save weight.

CW: You referred to a paper thin swinging arm. Did you make that from scratch?

Bolger: Yes. It’s made from chrome moly tubing, .040 in. thick, with about a 1.25-in. o.d. It’s welded together with No. 16 Eutectic low temperature rod. The ends are closed so the axle can’t slip back and out. It weighs 5 lb., a saving of about 4 lb. The pivot uses standard bronze bushings with a hardened steel sleeve. It’s stood up very well.

CW: I see a tensioner for the drive chain on the left swinging arm. Was this borrowed from the Bultaco trialer?

Bolger: No. It utilizes an idler wheel from a 450 Honda cam chain tensioner; the wheels are cheap to replace. The unit acts as a chain guide, and keeps the chain under moderate tension, so it doesn’t get sloppy during a long race. It gives you a bit of cushion, too, should you gear down hard. So it is easier on the gearbox, clutch, engine, all the way through. Bultaco has no provision for cushioning, as you know.

CW: What have you used for the front wheel?

Bolger: The latest Honda SL90 hubthe rear hub, because it takes a standard Bultaco axle, with one spacer. You don’t have to make up a special one. The rim is an Akront narrow flange, as used on the Sherpa T, so I can use a Barum 2.75-21 (standard is 3.00). This gives me pinpoint steering. I prefer a bike that steers well, rather than aviating and all that stuff. The front wheel weighs 9 lb. less than standard, which gives me a 17 lb. saving in wheels alone.

CW: How about some of these other bits and pieces?

Bolger: The brake pedal and footrests are copies of the ones Dick Mann engineered for Yankee. The pegs are not spring loaded, but they only retract 60 degrees, so you can always get them down. If a spring-loaded pedal gets clogged up with mud, it won’t return by itself, anyway, so why have a spring? For the brake pedal, I use a Honda pedal turned upside down. Both lever and pegs are hollow with notches to grip the boot in slippery conditions.

I’ve borrowed from factory racing practice in the treatment of the clutch cable, which swings over the top of the engine for easier access, rather than underneath. Likewise the casing over the countershaft sprocket has been notched for easier access.

The ignition box is placed up on the steering head, rather than under the tank. This was for the sake of appearance, but it probably stays cleaner behind the number plate.

I’ve got to give Honda credit for my number plate idea. These have rubber grommets which snap on to pins. I can pull them off with no tools. The same goes for the seat. The gas tank is also quickly detachable, without tools.

The handlebars are standard Honda CL350 with an extra inch welded onto both ends. As they bend fairly easily, they’re not prone to break. I’d rather bend bars than try to fix the whole front of the bike. I don’t want to have to fix my forks every time I go down. For the same reason, I use Tomaselli levers. They bend, but don’t break.

CW: How about that unusual throttle arrangement?

Bolger: It’s a combination throttle and compression release. You twist the throttle as usual to give it gas. It returns to a neutral position, and you twist the grip past that point to operate the compression release, for engine braking.

CW: Are the suspension units left standard?

Bolger: Yes. The rear legs are standard Betor shocks, and they seem to work properly with the reduced weight. The front tubes and springs are standard, although I had to change the oil in the forks, because of the loss in unsprung weight. While the wheel, being lighter, could oscillate at a greater frequency, the damping with the standard oil weight was not permitting the front end to rebound fast enough. The forks would slowly compress on washboard surfaces. Switching to 5W oil cured that.

CW: What did you do to the engine?

Bolger: I was primarily concerned with careful assembly. I’ve long since gotten over trying to get that last extra horse or two, because that isn’t the problem in winning.

Enlarging the transfer ports does make the Pursang torquier than standard. I cleaned up the other ports, and matched the cylinder to the base. The carburetor is standard, but I always jet rich and put up with fluffy running until the engine gets hot, in the interest of reliability. I feel the engine has bags of power and it’s foolish to look for more.

The flywheel and connecting rod are polished, as well as the outer flywheel. I also lightened the clutch basket with holes and polished it.

To make shifting smoother, I dovetailed the gears. The shifting dog is backcut at the base, so as soon as it catches, it encourages full, sure engagement. The holes and slots are also angled slightly. The only disadvantage here is a slight drag when downshifting, because you have to back the dogs up against this pressure. But it stops bounce-out when making quick gear changes.

I also cut the expansion chamber and rebent it to get better ground clearance.

It’s all a matter of careful assembly and refinement, which has paid off. I’ve had very little engine trouble.

CW: Do you contemplate any further changes to your machine?

Bolger: Right now, I’m working on an idea to change rake quickly, say, in 10 to 20 minutes. Right in the steering head. We use our bikes at Middleboro in a TT scrambles one week and next week we’ll go to a motocross. It just doesn’t figure that the suspension is right for all those things. Changing it with rake plates is all wrong because you get an arc at the axle which is awry when you cock the wheel, causing the wheel to heave as it turns.

CW: So, are you happy with what you’ve got?

Bolger: Yes. Not only does it look proper, but it’s very nice to ride. It aviates easier, turns nicer and stops quicker. And it makes up a lot for some of my other problems. Like, I should have quit 10 years ago. I cannot get around as quickly on a standard one.

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsRound Up

February 1970 By Joe Parkhurst -

Letters

LettersLetters

February 1970 -

Departments

DepartmentsThe Scene

February 1970 -

Features

FeaturesNight Rider

February 1970 By Stuart Munro -

Features

FeaturesHow To Teach Your Girl To Ride

February 1970 By David C. Hon -

Special Color Feature

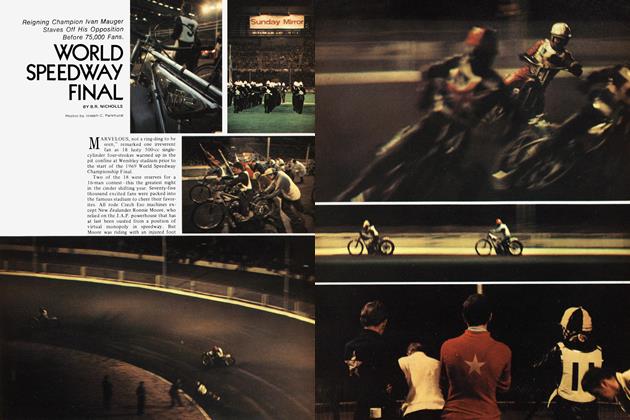

Special Color FeatureWorld Speedway Final

February 1970 By B.R. Nicholls

Current subscribers can access the complete Cycle World magazine archive Register Now

Dan Hunt

-

Development

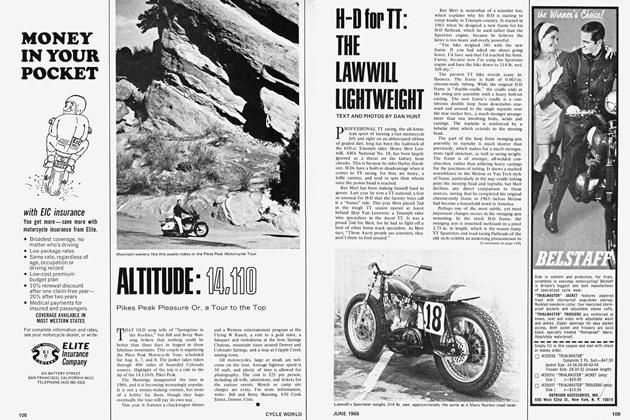

DevelopmentH-D For Tt: the Lawwill Lightweight

JUNE 1968 By Dan Hunt -

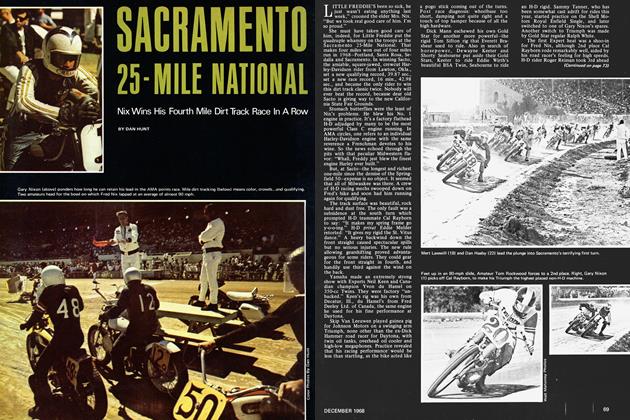

Competition

CompetitionSacramento 25-Mile National

DECEMBER 1968 By Dan Hunt -

Special Features

Special FeaturesFrank Heacox Sells Helmets. Lots of Them. But He Opposes the Helmet Law. He Is, You See, A Motorcyclist. And We Can Thank Our Lucky Stars.

APRIL 1970 By Dan Hunt