GENTLEMAN'S EXPRESS

Henry Manney

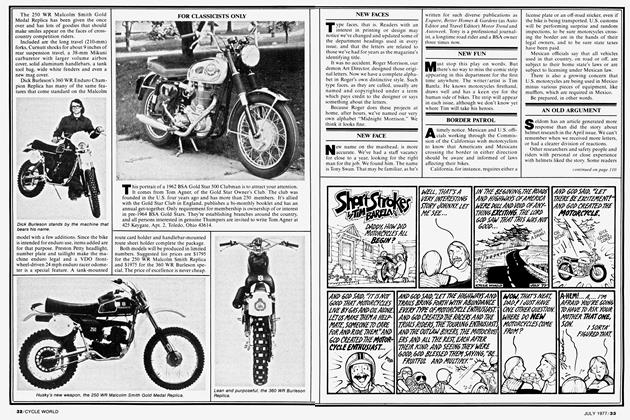

Dick Ford is one of those old (chronologically speaking) hot rod and machinery freaks with whom southern California abounds. At present he works for Briggs Cunningham’s Museum looking after the care, feeding and restoration of Briggs’ little gems and since Dick is a nice, neat and clean person who does nice, neat, clean and positively gorgeous work it looks as if he will stay there the rest of his life. He is undoubtedly a gent and so is his blown Honda 500, the worthy subject of this article.

Briggs collects interesting machinery like Rubirosa collected girls, although he shows a little more discrimination. One of his acquisitions in 1971 was a new 500-cc Honda Four, largely from thoughts of dropping it into some sort of racing car I suspect. However, the most mileage put on it was by Dick Ford, who used to go out for a spin once a week to keep the juices flowing and by 1974 approx, had amassed about 150 miles. The bike then became surplus to req. and Dick bought it off the boss as a runabout. This state of affairs continued until Dick was cleaning out under the bench one day and found a Pepeo Rootes-type supercharger as originally sold by Lou Fageol for use on Crosleys, etc., which, God knows, needed them. Rootes blowers were originally designed for use as air pumps in coal mines, or some such silly thing, and as they have two-geared Gibson-Girl rotators turning alternately in an oval casing, provide boost at rather lower rpm than centrifugal or vane blowers. They are pretty simple and in fact were designed back in the 1880s sometime, long before automotive application was thought of.

In the early 1950s these devices were sold pretty freely and in fact Dick’s Pepeo dates from that time; Cunningham bought one and had it installed on a 500-cc Fiat Topolino (see remarks Crosley above) by the celebrated Alfred Momo. Regardless of all this high-priced talent, two laps around the block and “it squirted the head gasket,” always a touchy point on flathead Mice, so the blower went into its 25-year sleep under the bench. I am an early blower convert, having had Ernie McAfee install one in 1950 on my hitherto gutless Crosley Hotshot. Of course the Crosley doesn’t have a head gasket, nor indeed a detachable head, but it does pave puny little valves and Siamese intake passages about the size of a worm’s gullet. The transformation was miraculous, being fast enough in spite of (1) my driving; (2) Crosley suspension; (3) Crosley threespeed gear box; (4) Crosley brakes to beat all but a couple of the fastest MGs at Pebble Beach. What the blower does is feed the combustion chamber all the fuel mix it can possibly use instead of relying on atmospheric pressure. A lot of rubbish has been written about blowers and how they will automatically blow up your engine; we never had an engine failure attributable to the blower. Of course you must run a comparatively low compression ratio, colder plugs, stiffen up the bottom end if you are going racing, not turn the blower too fast, and refrain from using 11,000 if 8500 was all you could get before. You can probably turn 11,000 as the blower is efficient but it is best to stay within design limitations. Those aluminum-eating rats that live inside engines get very hungry when the blower is running.

About the same time that the Pepeo was discovered, Dick got a workshop manual for the Honda 500. Looking at the drawing of the clutch gubbins, Dick saw a nice fat gear and a nice fat incandescent bulb marked “Idea” lit up in his head. Having obtained the blower by fair means or foul, he started plotting and by 1975 had enough data to actually start work. What it amounted to, he tossed off diffidently, was adding an idler gear to go between the clutch and blower drive gears, fabricating a casing to contain same, fiddling up an intake manifold, getting another carb plus adapter, and finding a way to fit the whole business in neatly. First job was to take his drawings up to Clyde Sturdy (another old Bonneville racer) at Associated Gear in L.A., and while that was going on to build the casing. A “picture frame” of the perimeter of 3A-in. alloy was cut out, the outer cover of % ditto, and the back of VA prepared and the whole business taken to Steve Jentres for heli-arcing together and to the clutch cover. There was also a bit of neating up and fabrication of a finned blower end plate before a triangular support was built up to support the Pepco’s non-driving end. It is typical of attention to detail that the support hole for the bracket was drilled where no grease or oil could leak out. The next move was to build

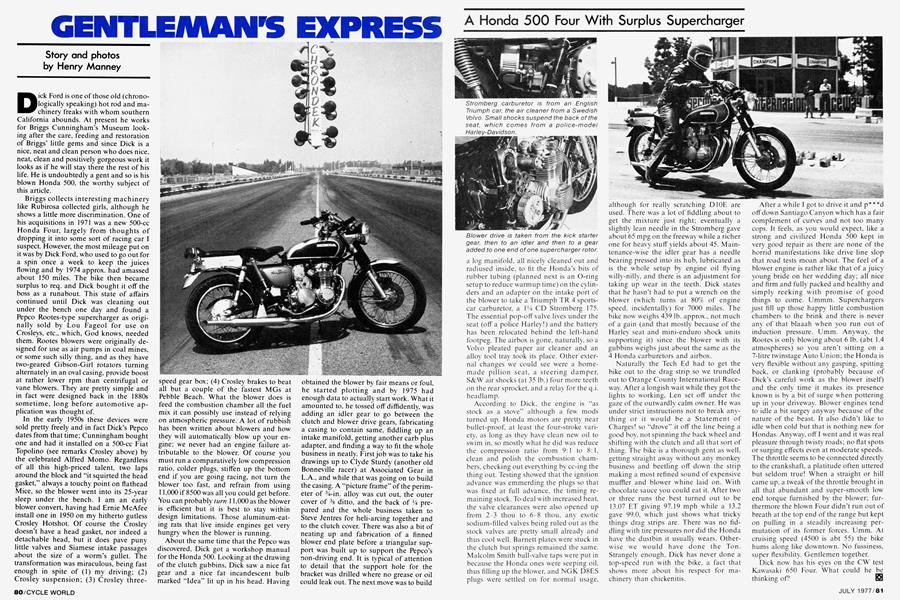

a log manifold, all nicely cleaned out and radiused inside, to fit the Honda’s bits of rubber tubing (planned next is an O-ring setup to reduce warmup time) on the cylinders and an adapter on the intake port of the blower to take a Triumph TR 4 sportscar carburetor, a \lA CD Stromberg 175. The essential pop-off valve lives under the seat (off a police Harley!) and the battery has been relocated behind the left-hand footpeg. The airbox is gone, naturally, so a Volvo pleated paper air cleaner and an alloy tool tray took its place. Other external changes we could see were a homemade pillion seat, a steering damper, S&W air shocks (at 35 lb.) four more teeth on the rear sprocket, and a relay for the q.i. headlamp.

According to Dick, the engine is “as stock as a stove” although a few mods turned up. Honda motors are pretty near bullet-proof, at least the four-stroke variety, as long as they have clean new oil to swim in, so mostly what he did was reduce the compression ratio from 9:1 to 8:1, clean and polish the combustion chambers, checking out everything by cc-ing the thing out. Testing showed that the ignition advance was emmerding the plugs so that was fixed at full advance, the timing remaining stock. To deal with increased heat, the valve clearances were also opened up from 2-3 thou to 6-8 thou, any exotic sodium-filled valves being ruled out as the stock valves are pretty small already and thus cool well. Barnett plates were stuck in the clutch but springs remained the same. Malcolm Smith ball-valve taps were put in because the Honda ones were seeping oil, thus filling up the blower, and NGK D8ES plugs were settled on for normal usage, although for really scratching D10E are used. There was a lot of fiddling about to get the mixture just right; eventually a slightly lean needle in the Stromberg gave about 65 mpg on the freeway while a richer one for heavy stuff yields about 45. Maintenance-wise the idler gear has a needle bearing pressed into its hub, lubricated as is the whole setup by engine oil flying willy-nilly, and there is an adjustment for taking up wear in the teeth. Dick states that he hasn't had to put a wrench on the blower (which turns at 80% of engine speed, incidentally) for 7000 miles. The bike now weighs 439 lb. approx., not much of a gain (and that mostly because of the Harley seat and mini-enduro shock units supporting it) since the blower with its gubbins weighs just about the same as the 4 Honda carburetors and airbox.

Naturally the Tech Ed had to get the bike out to the drag strip so we trundled out to Orange County International Raceway. After a longish wait while they got the lights to working, Len set off under the gaze of the outwardly calm owner. He was under strict instructions not to break anything or it would be a Statement of Charges! so “drove” it off the line being a good boy, not spinning the back wheel and shifting with the clutch and all that sort of thing. The bike is a thorough gent as well, getting straight away without any monkey business and beetling off down the strip making a most refined sound of expensive muffler and blower whine laid on. With chocolate sauce you could eat it. After two or three runs the best turned out to be 13.07 ET giving 97.19 mph while a 13.2 gave 99.0, which just shows what tricky things drag strips are. There was no fiddling with tire pressures nor did the Honda have the dustbin it usually wears. Otherwise we would have done the Ton. Strangely enough, Dick has never done a top-speed run with the bike, a fact that shows more about his respect for machinery than chickenitis.

After a while I got to drive it and p* * *d offdown Santiago Canyon which has a fair complement of curves and not too many cops. It feels, as you would expect, like a strong and civilized Honda 500 kept in very good repair as there are none of the horrid manifestations like drive line slop that road tests moan about. The feel of a blower engine is rather like that of a juicy young bride on her wedding day; all nice and firm and fully packed and healthy and simply reeking with promise of good things to come. Ummm. Superchargers just fill up those happy little combustion chambers to the brink and there is never any of that blaaah when you run out of induction pressure. Umm. Anyway, the Rootes is only blowing about 6 lb. (abt 1.4 atmospheres) so you aren’t sitting on a 7-litre twinstage Auto Union; the Honda is very flexible without any gasping, spitting back, or clanking (probably because of Dick’s careful work as the blower itself) and the only time it makes its presence known is by a bit of surge when pottering up in your driveway. Blower engines tend to idle a bit surgey anyway because of the nature of the beast. It also didn’t like to idle when cold but that is nothing new for Hondas. Anyway, off I went and it was real pleasure through twisty roads; no flat spots or surging effects even at moderate speeds. The throttle seems to be connected directly to the crankshaft, a platitude often uttered but seldom true! When a straight or hill came up, a tweak of the throttle brought in all that abundant and super-smooth low end torque furnished by the blower; furthermore the blown Four didn’t run out of breath at the top end of the range but kept on pulling in a steadily increasing permutation of its former forces. Umm. At cruising speed (4500 is abt 55) the bike hums along like downtown. No fussiness, super flexibility. Gentlemen together.

Dick now has his eyes on the CW test Kawasaki 650 Four. What could he be thinking of? E9

A Honda 500 Four With Surplus Supercharger