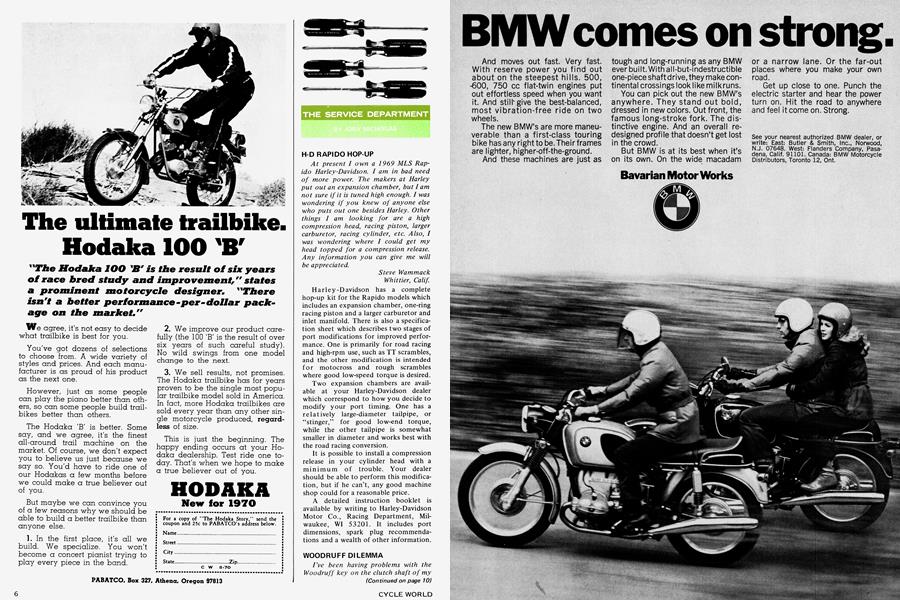

THE SERVICE DEPARTMENT

JODY NICHOLAS

H-D RAPIDO HOP-UP

At present I own a 1969 MLS Rapido Harley-Davidson. I am in bad need of more power. The makers at Harley put out an expansion chamber, but I am not sure if it is tuned high enough. I was wondering if you knew of anyone else who puts out one besides Harley. Other things I am looking for are a high compression head, racing piston, larger carburetor, racing cylinder, etc. Also, I was wondering where I could get my head topped for a compression release. Any information you can give me will be appreciated.

Steve Wammack Whittier, Calif

Harley-Davidson has a complete hop-up kit for the Rapido models which includes an expansion chamber, one-ring racing piston and a larger carburetor and inlet manifold. There is also a specification sheet which describes two stages of port modifications for improved performance. One is primarily for road racing and high-rpm use, such as TT scrambles, and the other modification is intended for motocross and rough scrambles where good low-speed torque is desired.

Two expansion chambers are available at your Harley-Davidson dealer which correspond to how you decide to modify your port timing. One has a relatively large-diameter tailpipe, or “stinger,” for good low-end torque, while the other tailpipe is somewhat smaller in diameter and works best with the road racing conversion.

It is possible to install a compression release in your cylinder head with a minimum of trouble. Your dealer should be able to perform this modification, but if he can’t, any good machine shop could for a reasonable price.

A detailed instruction booklet is available by writing to Harley-Davidson Motor Co., Racing Department, Milwaukee, WI 53201. It includes port dimensions, spark plug recommendations and a wealth of other information.

WOODRUFF DILEMMA

I’ve been having problems with the Woodruff key on the clutch shaft of my five-speed Bultaco Matador. I have sheared off three of them and can’t tell what causes it. My only guess is that I may have allowed the rear chain to get too loose, thus allowing excessive chain snatch.

(Continued on page 10)

Continued from page 6

Would the primary chain tensioner (yes, primary) that is now used on the Sherpa-T fit on my Matador, and would that help?

I would also like to know if the new high performance kit would he all right to install on my bike since mine is one of the first five-speed Matadors (24-mm IRZ carb, etc.), and the kit is designed for the newer Matadors. What would be the effect of adding just the expansion chamber and leaving the small carburetor?

A.J. Cox Tucson, Ariz.

The Matador has a tapered mainshaft on which the clutch mounts. It is very possible that the taper of the shaft and the taper inside the clutch hub are not exactly the same, which would make it more difficult to tighten the clutch hub down properly. The two tapers should take most of the torque from the engine with the Woodruff key doing little more than serving as an aligning device, and therefore not be subjected to very much strain.

Remove the clutch hub and apply a small amount of fine valve-grinding compound, mixed with light machine oil to dilute it somewhat, to the tapered mainshaft. Then put the machine in high gear and block the rear wheel so that you can lap in the clutch hub with the mainshaft. Do this using light to moderate pressure and remove the clutch hub occasionally to make certain that you are getting a good, smooth pattern on the shaft and inside the clutch hub.

When a good surface is obtained between the two, clean off both parts with gasoline and dry them. Then smear some ordinary blackboard chalk on the tapered mainshaft and reassemble the unit, making sure you get the mainshaft nut quite tight. This will make the clutch hub more difficult to remove next time, but you shouldn’t be bothered with sheared Woodruff keys any longer.

The spring-loaded chain tensioner from the late model Sherpa-T models will not fit in your Matador, as your machine doesn’t have a locating boss on the inner crankcase to receive the chain-tensioner pivot shaft. Also, the fact that your rear chain is a little loose shouldn’t cause the clutch key to shear any more rapidly, and it’s much easier on the drive-side mainshaft bearing if the chain is loose and not tight.

(Continued on page 12)

Continued from page 10

The ISDT high-performance kit will fit on your Matador and will show an appreciable increase in horsepower over the standard set-up. Merely putting an expansion chamber on a stock motorcycle will increase little more than the noise level.

SHIFTLESS ENFIELD

I have a 1961 Royal Enfield (700) modified for TT and scrambles. When attempting to shift up or down with more than 3000 rpm, all I get is a solid neutral. At times, when down-shifting, it will go into gear and slip out again. By using the kill button, I can obtain a more desirable gear change, but R ys still have to be kept relatively mild. The clutch is properly adjusted and works fine. Could you offer any suggestions on how to fix my no-shift transmission. Keep up the good work on your superior magazine.

Dave Schroepfer New Ulm, Minn.

Your problem is not a very common one as far as I know. The shifter forks in the Royal Enfield are very substantial and rarely give trouble. However, I would suggest that you dismantle the gearbox and have a look at the engagement dogs on the gear wheels inside. These dogs should have very nearly square corners on the ends, or they will have a tendency to push themselves away from the gear they are engaged with under acceleration or engine braking, as well as during gear shifts, which can cause bent shifter forks. Some of the gears have recesses cut into them which accept the engagement dogs, and these must be square as well.

The engagement dogs are case hardened in most instances, so filing them square would not do much good. It looks as though you will have to replace some gears.

WHEEL ALIGNMENT

Several months ago I requested an answer to a high speed wheel wobble problem that occurred with my Suzuki T 500 and the wife’s T 305. Although there are many reasons for this problem, I discovered a way to cure ours, which might be of some use to others.

It seems that the adjusting notches on the swinging arm just do not accurately align the rear wheel. I solved this by using a (tMolly anchor” dry wall fastener as a gauge. Any similar device will work, as long as it can be placed against the rim of the wheel and between the outsides of the swinging arm. By screwing in the holt and locking it in place with a second nut (removed from another “Molly anchor”), a very precise measurement can be made between the swinging arm and the rim of the wheel. In effect, this handy tool becomes a poor man ’s inside caliper. By removing the bolt from its sleeve and replacing it in the opposite end the tool will be given a Jlat base to use against the rim of the wheel.

(Continued on page 14)

Continued from page 12

At present, I have reached the stage in cycling in which 1 wish to do as much maintenance as possible within the limits of my ability and equipment; therefore, I plan to buy a Dunleer Timing Tester. In conjunction with this device, I will need a type of indicator which will give me the correct location of the piston. Where can I purchase such a device? It must be graduated in millimeters, as this is what my owner’s manual refers to. One more question. How can my 500/5 be improved for smoothness on the low end for street riding. At present I am using a 15-tooth counter sprocket and a 350 tire on the rear. All other components are stock.

John Bedient Cedar Rapids, Iowa

I discussed wheel alignment in this column in the June issue of CW, but perhaps I didn’t go into it deeply enough.

Your idea for aligning the rear wheel is certainly a clever one, but I think you missed my point. I mentioned that the notches on the swinging arm sometimes do not correspond to the actual alignment of the wheel. The alignment of the wheel in the swinging arm is of little consequence, as some swinging arms are not the same on both sides due to the design of the rest of the frame or other considerations such as the placement of the countershaft sprocket in relation to the rear wheel sprocket.

The important consideration concerning wheel alignment is that the rear wheel must be perfectly aligned with the front wheel, and not with the sides of the swinging arm or even the sprockets and chain. This is easily accomplished by stretching a piece of string along the outer edges of the tires and adjusting the rear wheel until it aligns perfectly with the front wheel.

A dial indicator which will screw into the spark plug holes to measure the correct distance of the piston from top dead center is available through your local Suzuki dealer.

If your low-speed roughness is in the form of a vibration, I suggest you check the engine mounting bolts and make certain they are tight.

(Continued on page 16)

Continued from page 14

SCHOOL FOR SERVICE

I have recently begun reading CYCLE WORLD. My curiosity about motorcycles is becoming limitless. I was the owner of a small 90-cc Honda, but unfortunately, it was stolen from me before I got a chance to discover what riding was all about.

I am interested in motorcycle service and repair, and I was wondering if you could recommend any school or program where courses are offered. I am inspired by your Service section of the magazine. There seems to be nothing about a motorcycle that your department doesn’t know. Any help you could give me in regards to attaining qualified training in servicing would be greatly appreciated.

Isiah Charleston APO San Francisco, Calif

Sorry to hear that your bike was stolen. Motorcycle theft is certainly a serious problem these days, and any precautions one can take against such an occurrence should be exercised.

We are impressed by your interest in the service and repair end of motorcycling and wish to encourage others like yourself to follow in that direction. There is a chronic shortage of really qualified mechanics, and the really good ones are enjoying high salaries and good working conditions.

I know of at least two schools that offer training in motorcycle mechanics in the Los Angeles area. One is the Woodland Hills Skill Center, which offers a rather short course and ends with a certificate. The other is the Los Angeles Trade Technical College, which offers a two-year program culminating in a degree in motorcycle engineering. A graduate of one of these schools, and especially the latter, is a highly-qualified man who will have no trouble in securing a well-paying and rewarding job.

FOUR-CYCLING TWO-CYCLE

My Yamaha DT-1 developed a severe miss when under load at high rpm in fourth and fifth gears. I was informed by a dealer that the condition is called four-cycling and is caused by too rich a mixture. With this information in hand, I rushed home and replaced the 160 main jet with a 150 and dropped a new jet needle to the last notch; but, alas, though the onset of four-cycling was shifted to a higher rev range the condition persisted, and the machine seemed to lose some low-range power. I checked the timing, added a new plug, and thoroughly cleaned the carburetor, to no avail. On a friend’s tip, I pulled the engine and cleaned the crankcase with gasoline, lest dirt, etc. in the cases be fouling the plug. And, though the crankcase was completely clean except for some very clear residual oil, the problem disappeared, and I was able to use the original carburetor jetting.

Since I do not understand why the problem was solved, I will appreciate an explanation of four-cycling in your column. I would also like to know how the main jet and jet needle affect the mixture and machine performance over the range of throttle openings.

John Jamieson Atlanta, G a.

The dealer was quite right when he explained that an over-rich mixture was causing the four-cycling, and you did the correct things to try and alleviate the problem.

However, unless there was a considerable amount of oil in the crankcase, I don’t understand why the problem occurred with the standard 160 main jet. The only reason I can think of is that your Autolube pump is set up too high, and the engine is being fed more oil than it needs. Another possibility is that there was some dirt in the carburetor body in the area of the choke, which was causing an over-rich mixture.

(Continued on page 18)

Continued from page 16

The needle position controls the mixture from approximately 1/4 to 3/4 throttle opening. The needle is tapered toward the lower end and fits into the needle jet which is of a specified diameter. As the throttle is opened and the needle rises, more fuel is admitted to mix with the greater amount of air the engine needs at higher rpm. By lowering the needle, you were leaning out the mixture, which could have resulted in piston seizure!

The main jet controls the mixture from 3/4 to full throttle, and slightly affects the needle mixture as well, if a large change in main jet size is made.

Provided the engine is still stock, you should stick to the manufacturer’s recommendations regarding carburetor settings.

SIDECAR TRAIL

I have hitched a Watsonian Monza sidecar to a Honda 750. After making all the recommended adjustments such as lean out, toe in, stiffer suspension, etc., I find I have a great combination except for one problem: heavy steering. The 750 has 3. 74 in. of fork trail. Ami right in believing this to be the cause of the difficulty? If so, do you have any suggestions as to how the amount of trail could be reduced? Would a smaller-diameter front wheel help?

Bill Par melee Fairfield, Conn.

You are correct in assuming that the trail is the culprit. The Honda CB 750 was designed as a solo machine, and as far as I am able to determine, Honda is not planning to come out with different triple clamps to reduce the trail for sidecar use. Hence, you will have to alter your existing units.

A good machinist could machine a new lower triple clamp with the aid of a milling machine which would extend the fork tubes out farther by 1-1 V¿ in., which should give satisfactory results. There is no hard-and-fast formula for computing the amount of trail needed for your application, and it will therefore be a matter of experimentation. Of course, the top triple clamp would have to be heated and bent slightly to make it align with the new lower clamp.

The Harley-Davidson Servi-Car has an adjustable triple clamp assembly which uses slots on the lower clamp to move the forks and alter the trail. It might be possible to get some ideas by studying it.

The rake will also be changed slightly by extending the lower triple clamp but not enough to make much difference. [Ö1

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsRound Up

August 1970 By Joe Parkhurst -

Letters

LettersLetters

August 1970 -

Departments

DepartmentsThe Scene

August 1970 By Ivan J. Wagar -

Special Features

Special FeaturesThe Dragster: How And Why

August 1970 By Dan Hunt -

Features

FeaturesThe Princess & the Peasant

August 1970 By Cecil P. Mack -

Competition

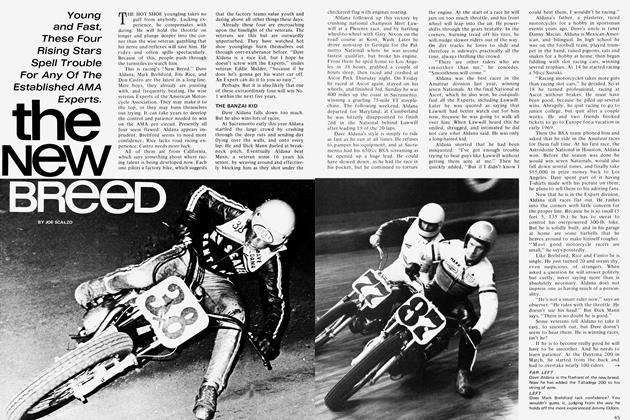

CompetitionThe New Breed

August 1970 By Joe Scalzo