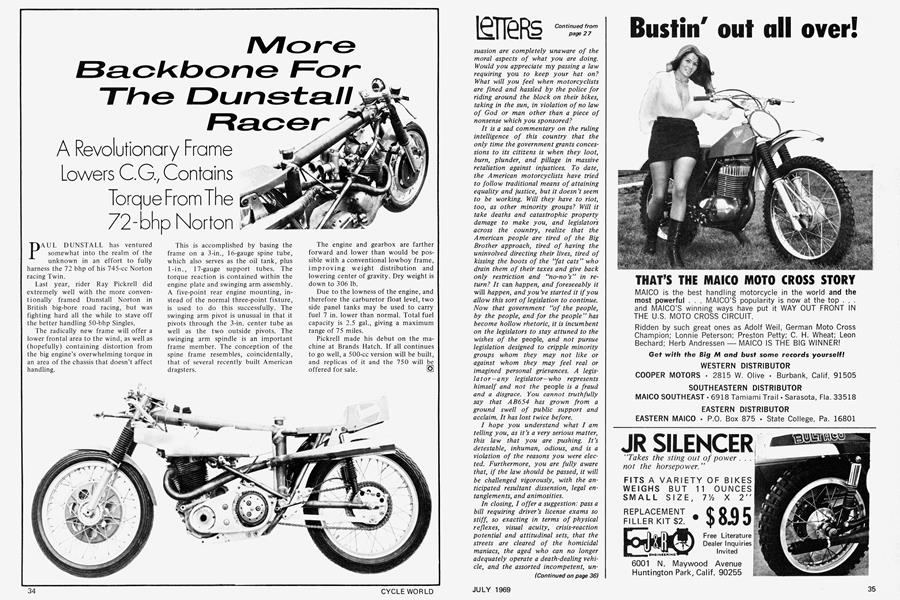

More Backbone For The Dunstall Racer

A Revolutionary Frame Lowers C.G., Contains Torque From The 72-bhp Norton

PAUL DUNSTALL has ventured somewhat into the realm of the unknown in an effort to fully harness the 72 bhp of his 745-cc Norton racing Twin.

Last year, rider Ray Pickrell did extremely well with the more conventionally framed Dunstall Norton in British big-bore road racing, but was fighting hard all the while to stave off the better handling 50-bhp Singles.

The radically new frame will offer a lower frontal area to the wind, as well as (hopefully) containing distortion from the big engine’s overwhelming torque in an area of the chassis that doesn’t affect handling.

This is accomplished by basing the frame on a 3-in., 16-gauge spine tube, which also serves as the oil tank, plus 1-in., 17-gauge support tubes. The torque reaction is contained within the engine plate and swinging arm assembly. A five-point rear engine mounting, instead of the normal three-point fixture, is used to do this successfully. The swinging arm pivot is unusual in that it pivots through the 3-in. center tube as well as the two outside pivots. The swinging arm spindle is an important frame member. The conception of the spine frame resembles, coincidentally, that of several recently built American dragsters.

The engine and gearbox are farther forward and lower than would be possible with a conventional lowboy frame, improving weight distribution and lowering center of gravity. Dry weight is down to 306 lb.

Due to the lowness of the engine, and therefore the carburetor float level, two side panel tanks may be used to carry fuel 7 in. lower than normal. Total fuel capacity is 2.5 gal., giving a maximum range of 75 miles.

Pickrell made his debut on the machine at Brands Hatch. If all continues to go well, a 500-cc version will be built, and replicas of it and the 750 will be offered for sale.