THE SERVICE DEPARTMENT

JOHN DUNN

SHUDDER

I have a slight problem with my 1968 BSA Lightning. The front brake, which I like very much except for one thing, tends to shudder when placed under an all-on stop. What could be the possible cause of this shudder? When I ordered my bike I requested that it be equipped with the Spitfire camshaft but BSA told me that both the Lightning and the Spitfire had the same camshaft. Can I get a hotter cam for my bike? If so, do you approve of a Harman & Collins cam?

A. Gudmundss Reykjavik, Iceland A front brake that shudders or judders under conditions of heavy braking

is usually the result of an oval or distorted brake drum. Remove the front wheel and have the drum checked for “run-out.” If your machine is still covered by the manufacturer’s or the dealer’s warranty, insist on a replacement. The other alternative is to have the drum retrued in a lathe. Sometimes it is necessary to remove a great deal of material to get the drum round. This latter procedure results in the drum diameter being oversize. At a later date, when heavy brake shoe wear has taken place, it is possible for the brake actuating cam to go “over center,” causing the brake to lock on. There should be no need for me to expand on what the result of this condition would entail. The apparent shudder could also be caused by either loose steering head bearings, or worn fork slider bushes.

The Lightning and Spitfire models are equipped with identical camshafts. Harman & Collins does make some fine camshafts. However, if you do decide to go this route, get the firm’s recommendation on the most suitable valve springs.

SHOCKING SITUATION

I am very interested in your comments concerning rear shock absorber adjustment and steering head damper adjustment. I believe that most (if not all) rear motorcycle shock absorbers have several adjustment positions in regard to tension. Could you please explain specifically what adjustment is best for what type of terrain and what weight rider /load? I also am interested in your comments regarding the use of the steering damper in various types of terrain and riding conditions.

It is realized that rider preference is probably the answer to my confusion, but perhaps there is a more scientific explanation which might benefit me as well as your readers.

Robert H. Widmann Santa Monica, Calif.

When you get down to the “nittygritty,” suspension is a. very complex business. Like all dynamic systems, the best configuration for any given set of conditions is a compromise. I’ll comment on rear suspension at this time, though, in the final analysis, both front and rear have to be considered as a whole. No matter what the application is, there are several major considerations that have to be taken into account and adequately catered to if the compromise is to be highly acceptable. These are traction, vehicle stability, control and rider comfort. Your questions are directly related to the rear suspension units and their relation to rider/weight considerations.

The majority of manufacturers equip the rear suspension units with a spring that will maintain a certain frame attitude with an average weight rider ( 160 lb.) under normal (those for which the machine was designed) operating conditions. If a much heavier rider (240 lb.) sits on the machine, the rear suspension particularly will compress a much greater amount, which, in turn, because of the changed attitude of the frame, will alter the steering geometry and weight distribution. Thus the handling characteristics of the machine usually are adversely affected. To compensate for the increased rider weight, it is necessary to increase the spring strength to retain the desired frame attitude. Many rear units today are provided with an adjustment to increase spring tension. This adjustment will affect only the initial force applied by the spring; it does not alter the spring rate. It still will take the same amount of weight to fully compress the spring. If the suspension “bottoms out” (spring fully compresses) with the heavier rider, it will be necessary to go to a higher rate spring (stronger spring). When selecting the stronger spring, do not overdo it. Chose a spring rate that will just carry your weight without the suspension bottoming under the severest condition normally experienced. If you go too strong, you might as well have no rear suspension.

(Continued on page 16}

Continued from page 14

To achieve maximum traction it is important that the rear wheel is on the ground at all times, during acceleration and braking. If the rear suspension is too stiff, the rear wheel will be thrown into the air even on a moderate bump. On the other hand, if it is too soft, the same thing will occur when the suspension bottoms out. When a spring is compressed, it possesses considerable energy, and, as soon as the forces that have compressed it diminish, it will release all of its potential energy. However, once this energy is released, the spring (and everything attached to it) does not become stationary. It will recoil and continue to oscillate (like a pendulum motion) until all its stored energy has been exhausted. This would not be good from a suspension point of view, because the rear wheel would continue to bounce on and off the ground long after the original bump had been hit. In fact, a great amount of motion would be transferred to the frame in its unsuccessful attempt to dampen the wheel oscillations. It is therefore necessary to dampen the wheel oscillations at their source. This is achieved hydraulically and is an integeral part of the modern suspension unit. It is important that the wheel return to the ground as quickly as possible and stay there. If the suspension is over-damped, the time taken for the wheel to make contact would be too long at high speed. It is therefore necessary to compromise in this area, also.

(Continued on page 18)

Continued from page 16

In conclusion, I can only advise that if the machine bottoms out, go to a slightly stiffer spring. If the rear wheel leaps off the ground under the slightest provocation, a softer spring is called for. If the machine tends to oscillate after hitting a bump, more damping is indicated. As you can see, this business is very complex and it is impossible to be specific without detailed knowledge.

Use of a steering damper today is mainly a case for rider preference. However, there have been a few machines in the past that were almost uncontrollable under certain conditions unless sensible use was made of the steering damper.

OFF-SEASON OILING

I have a 1966 74 Electra Glide. Each year I winterize it by taking the battery out and emptying the gasoline tanks. I squirt a considerable amount of oil in each cylinder through the plug openings. I replace the plugs and then turn the engine over several times with the kickstarter. One motorcycle dealer in my town told me this could bend a rod or crack a ring because of the added compression resulting from oil on top the pistons. I am worried. It did kick over very hard the first turn over after putting oil into the cylinders and replacing the plugs.

Ronald Pins Des Moines, Iowa

When laying up a machine for a considerable time, it is good practice to put a quantity of oil in each cylinder and then turn the engine over occasionally (perhaps once a month) to insure that the cylinders do not rust. Oil is a non-compressible fluid. If the quantity of oil in the cylinder exceeds the combustion chamber volume (the volume in the cylinder when the piston is at tdc), a connecting rod could easily be bent if the engine were spun over with the spark plug in place. If you are not sure how much oil there is in the cylinder, it is essential that the spark plug be removed and the engine turned over slowly. Insert the spark plugs afterward.

Many riders leave the gas tap “on” when their machines are parked. If the float chamber needle is not seating properly, it is possible for the cylinder to fill with gasoline if the intake valve is open. If the quantity of gasoline in the cyUnder is sufficient, it will “hydraulic” when the rider attempts to start the machine, quite often resulting in a bent connecting rod. As the piston comes up, it cannot compress the liquid, so something has to give, usually the connecting rod.

View Full Issue

View Full Issue

More From This Issue

-

Round Up

June 1969 By Joe Parkhurst -

The Scene

June 1969 By Ivan J. Wagar -

Letters

LettersLetters

June 1969 -

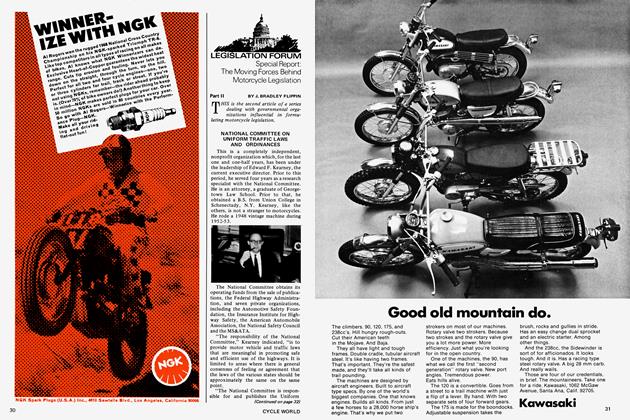

Legislation Forum

Legislation ForumSpecial Report: the Moving Forces Behind Motorcycle Legislation

June 1969 By J. Bradley Flippin -

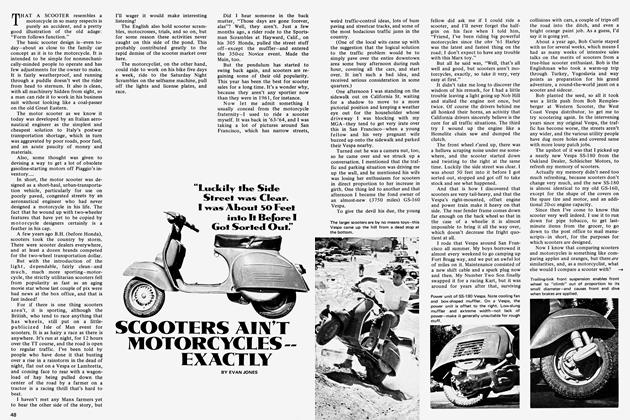

Offshoot Dept.

Offshoot Dept.Scooters Ain't Motorcycles-- Exactly

June 1969 By Evan Jones -

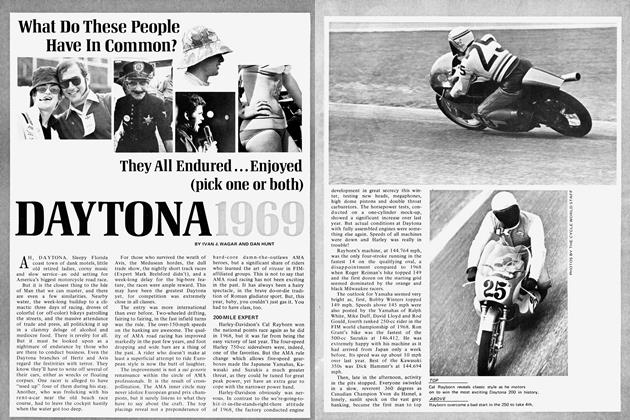

Competition

CompetitionDaytona 1969

June 1969 By Dan Hunt, Ivan J. Wagar