THE SERVICE DEPARTMENT

BY JOHN DUNN

A LONG, HAPPY LIFE

Is piston speed the main factor for long engine life? I have read that “low revvers” don’t necessarily last longer than “high revvers.” At 65 mph, the piston speed for the Honda 450 K-2 is 2157 ft./min. and 2184 ft./min. for the TR6R. Would the K-2 be as reliable as the TR6R? How does the bore/stroke ratio affect engine reliability?

Dennis Wong Berkeley, Calif.

Many factors influence engine life. Although mean piston speed provides some indication, it does not tell the whole story. Mean piston speed is directly related to engine speed and stroke. Therefore a “low rewer” with a long stroke could have, at maximum operating speed, a higher piston speed than a “high rewer” with an ultra short stroke.

The formula for obtaining mean piston speed is: engine speed (rpm) multiplied by the stroke (inches) divided by 6. An engine with a 3-in. stroke running at 8000 rpm would have the same piston speed as an engine with a 2.52-in. stroke turning 9500 rpm. The mean piston speed in both cases would be 4000 ft./min.

Only a few years ago, 3000 ft./min. was considered maximum. However, there have been great strides in the selection of materials and technical know-how, particularly since the end of World War II. Today, many racing engines operate at mean piston speeds in excess of 4000 ft./min.

MAXIMUM PISTON ACCELERATION

MPA = N2 x S 2189

N = engine speed (rpm)

S = stroke in inches

n = ratio of connecting rod length/stroke

Maximum piston acceleration provides a much clearer picture, as it is more closely related to actual inertia loads and conditions that influence piston ring control. In addition to rpm and stroke, a third value is introduced, the ratio of connecting rod length to stroke. Even if the rpm and stroke are already fixed, the MPA (maximum piston acceleration) is dependent on connecting rod length (measured between the centers of the small and big end bores).

(Continued on page 12)

Continued from page 10

However, this rule cannot be directly related to all engines. Bore size does influence the maximum permissible value for MPA. A small bore can use a higher value than a large bore. As a guide I would suggest the following approximate figures as maximum.

BUM DRUMS

I believe I have the solution to the problem of brake shudder on the BSA Twin leading shoe brakes (CW, June ’69). The drums on these brakes have very small grooves which look as if they are formed when the drum distorts when it is put into the hub. The drum is not machined down to the very bottom of these grooves and when water gets in, particularly during washing, some grease and oil gets into them. This is not scrubbed off when the brakes are used. The remedy is to have the drums machined to remove these grooves. Only about .002 in. need be taken out. Having this work done on my bike has made braking faster and smoother than when it was new-very important to me when I compete in road races.

David Ritchie Victoria, Australia

Thanks for your letter, David. I am sure that your remarks will be of value to others who run late BSA Twins. Any brake drum distortion would render the brake pretty ineffective. As you state, it is important not to remove more material from the drum than is absolutely necessary. Excessive removal of material, especially when the linings have worn down a bit, could cause the brake actuating cams to go over-center. This would cause the brake to jam on, which, needless to say, could prove highly dangerous.

It is always good practice to have the brake drum checked for roundness after it has been respoked or a new rim has been fitted.

TO PULL A HACK

I’m hot for sidecars and am considering four machines: a BMW R-60 with sidecar gearing, a Harley Sportster, a Triumph TR6R, and the Kawasaki Mach III. The problem is this: although the R-60 is supposed to be an ideal sidehack bike, the other three bikes apparently have more bhp and torque.

Would the Sportster with a couple of teeth off the counter-sprocket be a satisfactory power source or would it heat too much? Will the Watsonian hitch work with the Sportster?

Can the Kawasaki be properly cooled while pulling a hack? It seems to have plenty of power.

If the TR6R were selected, could I expect it to pull as well as the R-60?

Fred W. Reed Chapel Hill, N. C.

Of the machines you mention, I believe the BMW R-60 would be the wisest choice as a sidecar machine, unless you are looking for all-out performance. It is well adapted for this use as witnessed in Europe. Sidecar fittings are available; the engine is smooth and reliable. The new 750-cc BMW may be well worth investigating.

The TR6 may be a little bit more lively, and fittings and gearing are available. However, it probably would require more maintenance than the BMW.

(Continued on page 14)

Continued from page 12

Properly set up, the Sportster would make a great sidecar machine. It has the maximum power and good low speed torque so often lacking in many combinations. If fittings are not readily available, fabrication should not present a problem as the fixing points on the frame appear to be well located.

I would not advise using the Kawasaki Mach III for sidecar use. It is a great solo, but its power characteristics are not really suited to the broad demands of a good sidehack machine.

Believe me, Fred, I have tried sidecars and love them.

BASIC BLACK

I am rebuilding a 1954 Ariel Square Four and in the process of cleaning up the engine, I have scrubbed off all the dirt, carbon and burned-on oil from the aluminum exhaust manifolds, finned head, and cylinder barrel. Would I be wise to paint all this bright aluminum finning black to obtain better heat dissipation? If I do paint it, what temperature must the paint be capable of withstanding?

John Guttridge Islington, Ontario, Canada

Although polishing the external surface of an aluminum engine looks nice, the heat radiating ability of the polished surface is a fraction of the “as cast” condition. A mat or black surface will radiate more efficiently than a polished one.

“Sperex” is a high temperature paint intended for such uses and applications. It is recommended that the aerosol paint is applied at room temperature and baked on the component. However, this is not entirely necessary for engine or exhaust system applications. If the engine is brought up to normal operating temperature for a few moments, a lasting mat black finish is obtained.

BE-WHICHED

I have several questions regarding two-strokes and four-strokes. Which has a higher rpm potential? Which has a higher wear potential; which requires replacement of cylinders first? Which is more suitable for super modification for use on drag strips? Which is more free of vibration? I realize your answers will necessarily focus on the average twostroke and four-stroke.

Steven R. Dudley El Paso, Tex.

There always will be arguments among motorcyclists regarding the pros and cons of the two-cycle versus the four-cycle engine. Both types have advantages and disadvantages. Basically, the two-cycle engine is considered to be the simplest because it has fewer moving components. Although the two-stroke engine fires twice as many times as a four-stroke running at the same rpm, it does not develop twice as much power.

(Continued on page 16)

Continued from page 14

The four-stroke’s separate scavenging stroke pumps out almost all the burnt exhaust gases, but the two-stroke does not have a separate exhaust stroke. Scavenging is achieved mainly by the pressure of the gas in the cylinder. Over a relatively short speed range this process can be made to function fairly efficiently. However, at other points in the speed range, conditions in the combustion chamber can be very undesirable, resulting in high fuel consumption, irregular combustion and lack of power.

There is less scope for reasonable compromise with the two-stroke. To achieve good results the two-stroke must be designed for a specific application. Of course this also applies to the four-stroke when optimum performance is the prime consideration, but a greater degree of compromise is more readily achieved with this type. It is much easier for the designer to achieve a good, all-around performance combined with regular firing during idling and part load operation. The two-stroke has come a long way, even in the last 10 years, but I still believe that the two-stroke has more development ahead of it before it can be considered as forgiving as its four-stroke counterpart.

All factors considered, there is no reason why one type is better suited for ultra-high operating speeds.

The two-cycle engine requires a very close piston-to-cylinder wall clearance to maintain high pumping efficiency and port control. A four-cycle usually retains a higher percentage of its original efficiency with a greater degree of bore wear when compared with the twostroke. General bore wear is similar with both.

Unless you have considerable experience with the two-stroke, the four-cycle is the easier and more predictable to tune for optimum performance.

With any given crankshaft design the balance considerations will be almost the same. A well designed example of either type is capable of producing smooth operation throughout the intended speed range.

SPRING INTO ACTION

I have a Moto Guzzi V-7. The local roads are full of holes which constantly bottom out the forks. The fork travel is a maximum of 4.7 in. The recommended oil is 160 cc of Shell Tellux 33. I tried SAE 40 oil, but this did not help much. I have just put in 50 weight, but the forks still bottom out, though not as much. Could I go to 60 weight? Or what about 40 weight in a greater amount than specified. Would this do any damage? The springs can be compressed down to 4.1 in. Could I just stack up a 0.6-in. spacer above the spring to compress it? Does bottoming out the forks damage anything? Could the solutions to the above problem also be applied to my new Moto Guzzi 125 Scrambler?

(Continued on page 18)

Continued from page 16

Francis X. Scully Flushing, N. Y.

Before any changes are made to the damping oil viscosity, it is most important that you get the spring rate and set length “in the ball park.” I have no knowledge of the design characteristics of the Moto Guzzi V-7 front forks, so I will lay down some guide parameters.

First check fork travel from the fully extended length to the fully compressed length. This should be done with the springs removed. Next check the fitted length of the fork springs (length of spring when fitted, no weight on the machine and the forks fully extended). Now check the fully compressed length of the springs. By checking these points we try to determine if the springs are becoming coil bound when the forks are on full bump or if the forks are bottoming out internally. If the effective spring length (difference between fully compressed length and the set length) is less than the actual fork travel, they will become coil bound and use up all their potential energy. If this were the case there would be no benefit in fitting spacers, because the springs would still become bound and bottom out. A stronger spring is required in this case. If the fork travel is less than the effective spring length, you should decrease the fitted length of the spring by installing spacers, providing the new effective spring length (previous effective spring length less the length of spacer fitted) is not less than the fork travel.

For example, an effective spring length of 6 in. (fitted length, 18 in., less fully compressed length, 12 in.) is shorter than the fork travel, 8 in. (fully extended length, 18 in., less full internal travel, 10 in.). This would cause the spring to coil bind.

If, after you have the spring strength right, the forks are surging after hitting a bump, it then may be necessary to go to a thicker fork oil.

Continuous bottoming out of the forks will definitely cause damage. [O]

View Full Issue

View Full Issue

More From This Issue

-

Departments

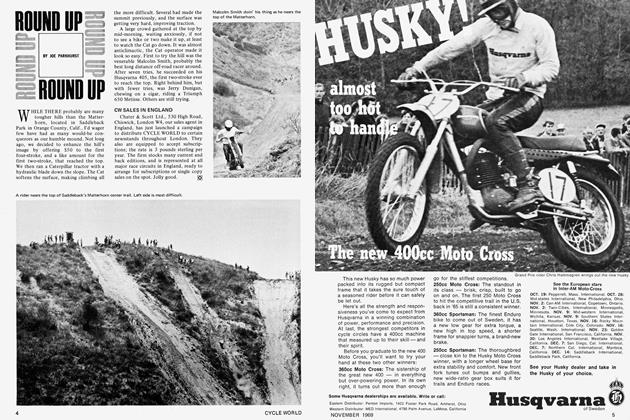

DepartmentsRound Up

November 1969 By Joe Parkhurst -

Departments

DepartmentsThe Scene

November 1969 By Ivan J. Wagar -

Letters

LettersLetters

November 1969 -

Features

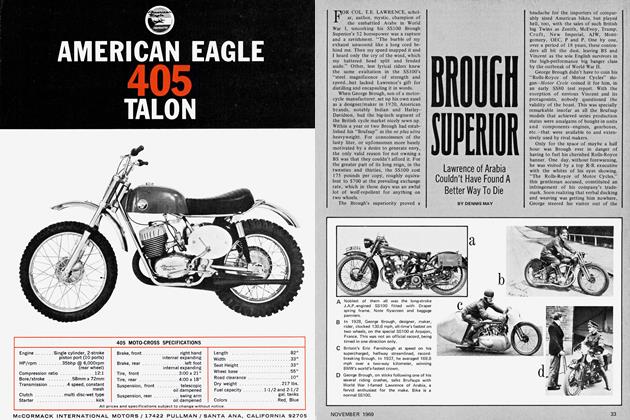

FeaturesBrough Superior

November 1969 By Dennis May -

Special Feature

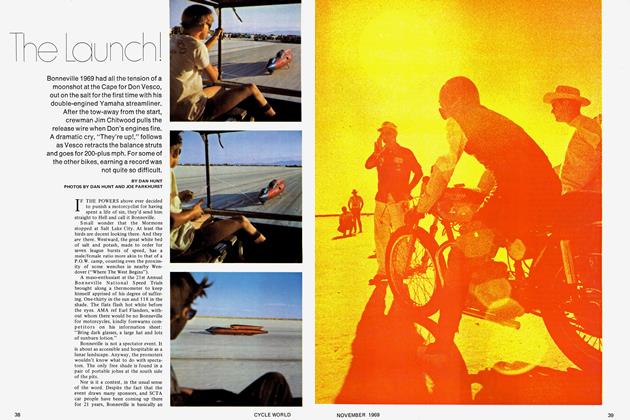

Special FeatureThe Launch!

November 1969 By Dan Hunt -

Competition

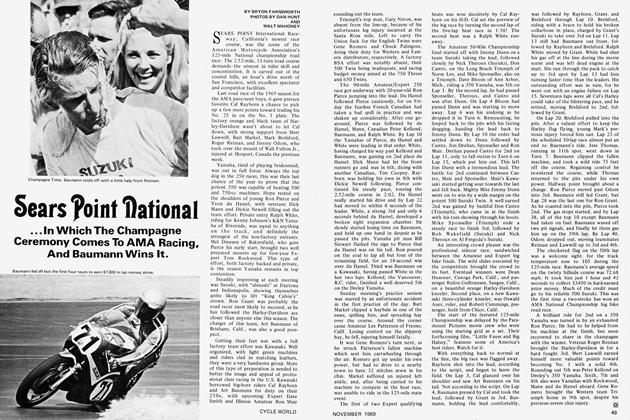

CompetitionSears Point National

November 1969 By Bryon Farnsworth