THE SERVICE DEPARTMENT

JOHN DUNN

BUNDA HONDITO IGNITION

My bike-buddy recently bought a dirt bike from a private party. It’s a Bultaco Bandito powered by a neatly installed Honda 350. My question concerns ignition. The bike now has a total-loss system, but we would like to eliminate the battery by modifying the stock alternator in some manner. Any suggestions?

T. W. Priester Westminster, Calif

The easiest and least expensive method to eliminate the battery is to purchase a “battery eliminator” kit. These can be purchased direct from the manufacturer, Conductor Systems, Inc., P.O. Box 1154, Pomona, CA 91769. There are several models available, 6 or 12 volt, positive or negative ground, so be sure to be specific when ordering a unit. The CSI Battery Eliminator, which sells for approximately $16, is easily installed and comes complete with a fully descriptive instruction sheet.

There are other ways of employing the alternator to supply current for ignition purposes only. However, a great deal of modification is required to effect this principle of operation. It is necessary to purchase special coils and condensers, to lock the ignition advance mechanism so that the alternator develops maximum flux at the same time that the points open and also to modify the internal wiring of the alternator, to provide current from just one set of coils. The labor costs alone would be in the $30 to $40 bracket, plus the cost of the additional parts required.

NOBODY LIKES A QUITTER

I have a Yamaha DTI that is giving me fits. The bike is used only for enduros and motocross. It runs perfectly for many miles, then just quits. I dismount (after crying a while) and file the points. Then it starts, runs well for a few more miles and dies again.

Dealers have suggested that I replace the points (I have, twice) or vent the case (also done), but the problem remains. I was forced out of the Burr Oak Enduro, but would like to make the Little Burr in Columbus.

Lee Wright Valparaiso, Ind.

I have not heard of a great number of DTl’s having contact breaker points trouble. However, I have noticed that most of the contact points manufactured in Japan deteriorate very rapidly after they have been filed. Short point life even after a new set has been installed could indicate a defective condenser. Also, when fitting new points, make sure that they come together squarely. If they are touching only on the edges, rapid wear will result. In other words, if the contact area is small, this small contact area will become electrically overloaded, will heat up and burn. If, after you have carried out the above suggestions, trouble still persists, carefully inspect the points. If material has transferred from the fixed point on to the pivot point, this indicates that the condenser is under capacity. Conversely, if material has transferred from the pivot point on to the fixed point, this would indicate that the condenser is over capacity. If the transfer of material is great, it would be well worth while to try a condenser of a different value.

SHIMMY LIKE KATE

I read your road test on the CB 450 Kl, and it was so good I bought one. For a conservative teacher, it was some move, and it appears to have been a poor one to boot! The problem is one of wobble or torsional flex. When going through a rapid “S” movement, by using my knees and shifting my weight, I can feel the bike “twist” or flex. It begins to oscillate; this increases with the rate of speed until I think the motorcycle will render itself and me into separate parts.

(Continued on page 16)

Continued from page 12

So far, we have replaced the tires, checked wheel alignment, balanced the tires, gone over a check list from Honda, checked the rims for trueness-all to no avail. I have approximately $1000 worth of very unstable motorcycle, and it’s taking all of the enjoyment out of what used to be a very enjoyable sport.

Edwin L. Daugherty Martensdale, Iowa

The Honda 450 is normally a very stable machine, so I know of no common fault that would cause a serious handling problem. I will therefore run through the usual causes of poor handling and hope that one or more prove useful in solving your problem.

Poor weight distribution can cause severe handling problems, particularly if additional weight is carried high or beyond either the front or rear wheel spindles. One of the most usual causes of this problem is badly fitted and incorrectly located saddle boxes or bags. If saddlebags are fitted, install them securely as far forward as possible, preferably in front of the rear wheel spindle. I have ridden several normally good handling machines that have been rendered extremely dangerous by poorly mounted and located saddlebags. Even a fairly heavy rider who is sitting too far back on the seat may cause the machine to be very unstable when cornering.

There are several seats on the market that some riders seem to prefer over the standard unit. Some of these seats, although they appear to be very comfortable, do not provide sufficient rider support because they allow far too much lateral movement. This results in sudden changes in weight distribution of such force that the machine will snake badly until speed is reduced or the rider’s weight is removed from the seat.

A defect in the steering head assembly, such as a cracked race or ball, can produce weird effects. Initially, check the condition of the steering head with the front wheel off the ground (no weight on the front wheel). If this does not indicate any malfunction and everything else fails to effect a solution, it may be profitable to dismantle the front end and carefully examine the steering head bearings.

Another critical component that, if not in first class condition, can cause serious navigational problems is the rear fork pivot bushes. The 450 is fitted with a rubber type of rear fork pivot bushing. A damaged bush will cause play which, in turn, will allow the frame to flex. A loose pivot bolt would have the same effect.

(Continued on page 18)

w • Continued from page 16

It is possible that one or both of the rear suspension units may have been damaged during shipment from Japan. With the springs removed, it should be possible to move the center rods in and out without any' irregular hard spots. Both units should be equally filled with the correct quantity of oil. The rear units have provision for adjusting the spring tension. Make sure that they are both adjusted to the same level. Some riders adjust the units unequally. They are definitely acting on some very misinformed assumption. Of equal importance, the front forks should be filled with the correct quantity of oil in each leg.

If you weigh over 220 lb., it may be necessary to install stronger rear springs to obtain the correct frame attitude.

If your problem persists, try getting a second or third opinion. Sometimes a fresh evaluation can reveal a fault that has been staring everyone else in the face.

TWO QUERIES

I have two questions. (1) What are the point dwell settings for 1965 CB-160 and 1967 CL-77 Hondas, and why aren’t dwell settings published in motorcycle articles? (2) What is the advantage and/or disadvantage to the type I and type II ignition systems used on Hondas?

John J. Gray Patuxent River, Md.

Contact breaker point “dwell” is not normally given for oneor two-cylinder motorcycles because it is not of any great value or importance. If the point gap is correctly set to within plus or minus 0.002 in. of the recommended setting, the ignition system will function perfectly throughout the manufacturer’s intended speed range. Dwell means nothing more than the amount of time that the points are closed. It is given in degrees of ignition cam rotation. In principle, the Honda type I ignition system can be likened to a single-cylinder system. The coil has plenty of time to “saturate” because of the long length of time that the points are closed, there being a separate coil, condenser and contact point for each cylinder. Out of 360 degrees of ignition cam rotation, the points are closed for at least 300 degrees.

The type II system employs one set of points to provide ignition for two cylinders. The ignition cam has two lobes, one for each cylinder. A single, twin lead coil is used to provide sparks for both cylinders. The cam lobes are equally spaced at 180 degrees, and provide a spark simultaneously to both cylinders every 360 crankshaft degrees. (The ignition cam turns only half a revolution (180 degrees) to one complete revolution (360 degrees) of the crankshaft.) However, the coil is discharged twice for each full rotation of the ignition cam, allowing only half as much time (dwell) for the coil to saturate when compared with the type I system. At very high engine speeds this could cause a problem as a result of insufficient time for the coil to saturate before it must discharge again.

(Continued on page 20)

Continued from page 18

The wider the point gap, the shorter the dwell, and, conversely, a small contact point gap will result in more dwell. However it is not good practice to close down the point gap any more than 0.002 in. smaller than standard in an effort to prolong the period of dwell. This will produce poor starting and greatly reduce point life.

As a final note regarding this subject, it should be fully understood that during the dwell period (points closed), a magnetic field is built up in the primary winding of the ignition coil. However, time is required to build up a full strength magnetic field. When a full strength magnetic field is obtained, the coil is termed to be saturated. At low speed, saturation is easily attained because of the relatively low speed of the ignition cam. However, at high speed, unless sufficient time is allowed for saturation by providing sufficient dwell, ignition efficiency will be inadequate.

PLAGUED

Vibration from the small single-cylinder engine of my motorcycle causes the threads to strip from the holes in the cylinder head which accept the carburetor-securing bolts. This has happened five times.

I have had the holes re-threaded four times, but after a couple of months the same fault occurs. A new block is very costly, and there is nothing wrong with the original one, but for this problem. Is there a cure?

Brent Walker Marion, N. C.

You do not say what make of engine you have or whether the cylinder head is made of aluminum or iron. So I cannot be specific about actual thread sizes.

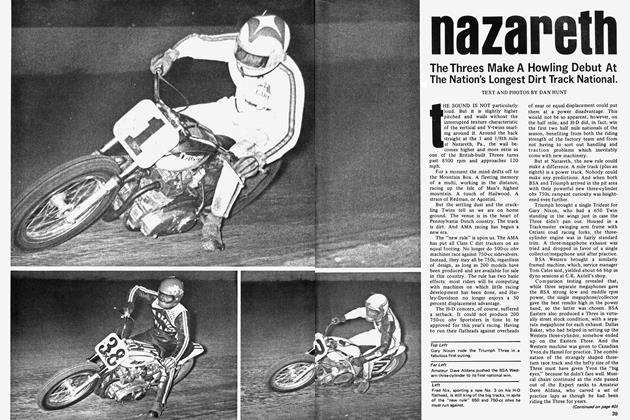

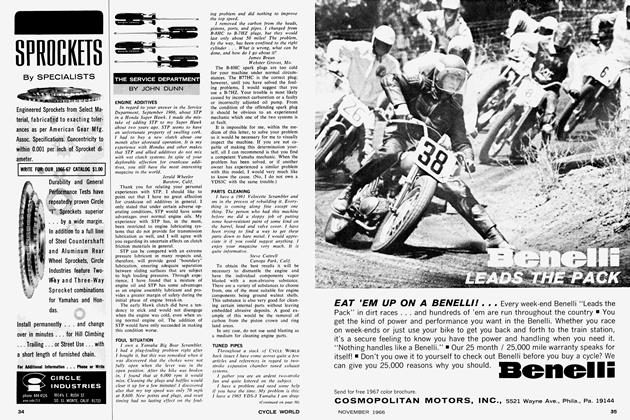

I suggest that you replace the bolts with studs. If you have sufficient material left in the head, drill and tap it to accept a coarse-threaded stud. A coarse thread is stronger, particularly if the head is made of aluminum. Drill and tap the hole to a depth of at least twice the diameter of the chosen thread size. Then make, or have made, a stepped stud. One end should have the same size thread you have tapped in the cylinder head, and the other end must be step ped down to suit the hole sizes in the carburetor flange. When installing the stud in the head, use "Lok-tite" on the thread. Make sure the large diameter end of the stud does not protrude beyond the head flange face when fully tightened. Ideally, it should be recessed approximately 0.005 in. below the sur face. See the sketch below. E~1

(Continued on page 22)

Continued from page 20