THE SERVICE DEPARTMENT

JOHN DUNN

DESERT TR5

I recently purchased a 1955 TR5 Triumph Trophy which is in excellent condition, having been carefully stored for the past eight years. I am in the process of making a new aluminum cylinder for this machine, which has a bore of 74 mm. This will increase the displacement of my machine from 500 to 687 cc. Piston castings have been made with the pin boss in approximately the right place, and sufficient material is available to construct any desired piston dome shape. What type of piston ring combination should I use, and what is the highest compression ratio I can use with gasoline. The machine is being set up for use in the desert. Will I be able to use the existing cylinder head?

Gene Woods Lawndale, Calif.

Many people are of the opinion that the higher the compression ratio is, the greater power the engine will develop. This is not necessarily true. With today's super premium gasolines (100-plus octane) it is possible to employ compression ratios as high as 12.5:1 without detonation. However, the point at which detonation occurs is not the ruling factor with respect to the ratio that will deliver optimum power. It is true that the higher the ratio is, the higher the cylinder pressure will be at the end of the compression stroke (before combustion), providing the piston crown shape does not interfere severely with the incoming gas during the overlap period. To obtain the highest temperature, and therefore the highest pressure, during combustion, it is essential that all the available oxygen is burned. This can only be achieved if the right proportion of fuel is evenly distributed throughout the combustion chamber and complete combustion occurs. To achieve the latter, it is essential that the combustion chamber is as compact as possible, and has good turbulence before and during combustion. It is difficult in a combustion chamber of the hemispherical type to obtain a relatively high ratio combined with a compact shape. I suggest that you first measure the volume of the cylinder head and work out the ratio. This assumes that you have a flat top piston with a 0.050-in. piston-to-head clearance with the head gasket fitted. This will give you some idea of the dome volume required to obtain the desired ratio. It can be safely assumed that a compression ratio of approximately 10.5:1 will give good results. In many cases an attempt to

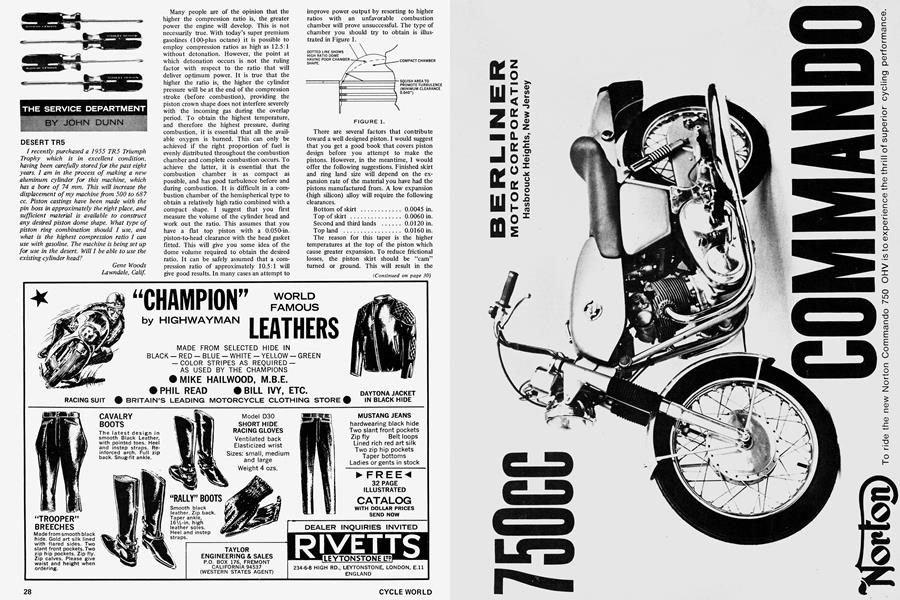

improve power output by resorting to higher ratios with an unfavorable combustion chamber will prove unsuccessful. The type of chamber you should try to obtain is illustrated in Figure 1.

There are several factors that contribute toward a well designed piston. I would suggest that you get a good book that covers piston design before you attempt to make the pistons. However, in the meantime, I would offer the following suggestions. Finished skirt and ring land size will depend on the expansion rate of the material you have had the pistons manufactured from. A low expansion (high silicon) alloy will require the following clearances.

Bottom of skirt 0.0045 in.

Top of skirt 0.0060 in.

Second and third lands 0.0120 in.

Top land 0.0160 in.

The reason for this taper is the higher temperatures at the top of the piston which cause greater expansion. To reduce frictional losses, the piston skirt should be "cam" turned or ground. This will result in the piston skirt being oval. The largest dimension should be at right angles to the piston pin and in keeping with the clearances listed above. The difference in diameter, when measured in line with the pin then at right angles to the pin, should be approximately O.OIO to 0.012 in. It is usual to leave the ring land areas round. It is also well worth chamfering the bottom inside edge of the piston at 45 degrees, almost to a knife edge. This has the effect of scraping the oil off the cylinder wall and reduces oil drag.

(Continued on page 30)

When laying out the ring grooves, make sure they have sufficient cross section to insure adequate mechanical strength. It also is important that there is adequate material thickness behind the ring grooves to provide a heat path from the top ring land. A build-up of heat in this area would result in ring and piston failure. If there is sufficient room, I would advise using three piston rings-two thin compression rings and a single oil control ring. It will probably be necessary to have rings specially made to suit the 74-mm bore. A straight, stainless steel top ring 0.045 in. wide, combined with an iron 0.062-in. second ring, having an outside bottom scraping edge, should do nicely for the compression rings. An 0.125-in. wide slotted iron oil ring will work fine. It is also good practice to chamfer the piston just below the oil ring groove and drill additional oil return holes. These holes should be drilled radially at right angles to the piston skirt. They should not be angled downward as oil can be forced up them when conditions of high piston acceleration exist. The compression rings should have approximately 0.002 in. side clearance in their grooves, where it is necessary to have 0.004 to 0.005 in. side clearance on the oil control ring. Oil is then allowed to pass behind the ring and be evacuated by the holes at the bottom of the ring groove. For racing purposes, a racing piston ring should have a radial thickness of D/26, where D is the cylinder bore diameter. This means that a ring for a 74-mm bore will require a radial thickness of 0.112 in. The compression ring grooves should only be 0.008 to 0.010 in. deeper than the radial thickness of the ring. It is essential that the ring grooves and lands are concentric and true with the piston skirt and that the pin hole is at right angles to the skirt.

You will be able to use the cylinder head from the TR5. Although it is under-valved, it will provide a fairly compact combustion chamber configuration as the head diameter is smaller than the new larger bore. Advantage can be taken of this because a squish band is provided that will induce additional turbulence during compression and combustion.

305 CONVERSION

You asked (CW, May '68) if anyone has had experience with 250-cc pistons in a 160-cc Honda. I have had some experience with installing 305-cc pistons, and the similarity being so close, I see little difference between 250 cc and 305 cc. (I was a Honda mechanic for five years.)

We used Harmon & Collins camshafts, Webco springs, and Honda Keihin 22-mm carburetors with Webco adapters and Webco air filters. I chose to use Teflon wrist pin buttons over standard clips.

The first thing we did was to measure the camchain pitch with a micrometer, as the cylinder had to be raised to clear the top of

the piston. We found this to be 0.309 in. Next we made a plate out of 0.025-in. aluminum to go under the cylinders, using a base gasket as a pattern.

Next we heated the cylinder to 350 F in a kitchen oven for half an hour and dumped the 160-cc sleeves out. We then fixed the cylinder block to a metal lathe facing plate and centered it with a dial indicator. We then measured the 305-cc sleeves and machined the cylinder block to receive them. When machining the cylinder block, we went through on some of the cooling fins, so we allowed 0.004-in. tighter than standard 305 sleeve fit, to prevent oil leakage.

We then shortened the sleeves on the lathe and cut the clearance on the stubs for crankcase clearances. A little extra length can be added by measuring from the top of the top crankcase to the top of the flywheels. We did this because the skirts of the pistons hit the flywheels and also have to be shortened in the lathe.

We set the top crankcase up in a radial drill press and fly cut the case and aluminum plate (to accept the 305-cc sleeve stubs) by bolting them together.

Then came the ticklish part. We made up a jig to hold the crankshaft and support the rods. Using an adjustable reamer, we reamed the rods out to receive the 305-cc wrist pins. We ran the press slow with cutting oil to prevent chatter marks, and got a superb finish.

We felt that machining the rods was better mechanically than using bushings in the pistons.

When installing the sleeves, we used liquid industrial Teflon to seal oil leakage. Also, we placed a heavy weight on the unit to hold sleeves down while cooling.

We assembled crankcases and installed pistons and rings on the rods. Next, we added two rollers of camchain and one new masterlink; we used two standard base gaskets-one above and one below the special plate. This thickness is close in thousandths of an inch to the length of chain that has been added. Then we slid the cylinder on.

For the head gasket we used an Apax circle gasket cutter to enlarge the standard 160-cc gasket. We carefully peeled the steel metal rings out of a 305-cc head gasket and installed them in the modified 160-cc head gasket. This also takes a little time and patience.

We replaced the cylinder head using the original camchain masterlink to time the valves. We had to rattail the frame mount holes about 0.062 in. to make the engine fit. We originally backed the cylinder studs up enough to compensate for the thickness of the plate we added, but after about 100-150 miles we had oil leakage around the cylinder base. We found the studs were gradually being pulled from the crankcase, and would not hold their torque settings of 18 lb. To remedy this, we used a large drill ground flat on the end to mill the cylinder head cover head nut flats. We found this new arrangement plus a larger breather installed in the cover completely cured oil leakage problems, and the studs would stay put and hold their torque settings.

The machine has the power of a 250-cc Bultaco up to speeds of 60-65 mph; then cubic inches win out. We did not balance the crankshaft, and some extra vibration is noticed although it is slight.

We used an energy transfer system using standard Honda 160 components. This system works well and has never given us any troubles. We use NGK D9H spark plugs. The machine starts exceptionally well.

(Continued on page 32)

Rand L. Crandall Longview, Wash.

I am sure your observations and experience will be of value to others who contemplate a similar modification to CB 160s.

For the record, the CB 160 has a bore and stroke of 50 by 41 mm, with an actual displacement of 161 cc. A 54-mm piston from a 250 would result in a displacement of 187.5 cc and the 60-mm 305 piston would increase the displacement to 232 cc.

Boring the 160 cylinder to accept the 305 sleeve horrifies me, mainly because (as you point out) the hole falls through into the fin area at some points. Theoretically this is very bad practice, as heat conductivity from the cylinder would be greatly impaired. However, the same thing often occurs when a 305 is equipped with a 350 kit. Ideally, a new cylinder should be made with extra material thickness to accept the larger sleeve. On the other hand I have not heard of any cases of 350 converted engines with overheating problems directly related to machining for the oversize sleeve.

If you are still using the original 160 valve sizes, the volumetric efficiency will fall off alarmingly at the upper end of the engine speed range.

CENTRIFUGAL TROUBLE

I own a 1966 Honda Trail 90 which has nearly 2000 trail miles on it. My problem is that the centrifugal clutch doesn't work properly. If I push the gear selector down and hold it there, then apply the throttle, the machine should not move, but the engine should only rev up. In my case it does not, but moves as if the selector were released.

Paul Roady Chatsworth, Calif.

Your problem most likely is no more than an incorrectly adjusted clutch operating mechanism. The Trail 90 is equipped with two systems. An automatic centrifugal clutch mechanism does not engage until the engine speed rises above idle. With the engine running at idle, the clutch is disengaged, even when the machine is in gear. With a rise in engine speed, the clutch engages automatically, and the machine moves away in low gear. When the gear change lever is depressed to engage second gear, the clutch disengages manually; and, as the gear lever is released, the clutch re-engages. This occurs when each gear change is made, either up or down. This latter mechanism works independently of the centrifugal clutch section. How-

ever, if the gear lever is held in a depressed position, there will be no drive through the clutch even though the centrifugal section has engaged at engine speeds above idle. The manual section, which is actuated by the gear lever, can be adjusted. In the center of the right-hand crank case cover there is an adjusting screw which is held in place by a lock nut. If the clutch does not disengage (which is the case with your machine), loosen the lock nut and turn the screw to the left. If the screw is turned too far to the left, this will allow the clutch to slip. Clutch slip can be felt on the kick starter. If the clutch is properly adjusted, there will be no drive when the gear pedal is depressed approximately 16 degrees from its normal resting position, even if the engine speed is above idle.

If the clutch does not respond to adjustment, there is an internal malfunction of the actuating mechanism. If this is the case, the right-hand cover should be removed without delay, for any broken pieces can cause extensive engine damage.

IT STILL OVERFLOWED

I have a Hodaka 90 set up for desert racing. It's a fantastic bike and a lot of fun, but a problem has developed which is going to drive me crazy. The bowl on the carburetor leaks, or overflows, through the little overflow tube that comes out of the bottom of the carburetor.

I tried to fix it all kinds of ways. I checked for dirt in the needle valve and seat. I checked to see if the float was sticking. Nothing was wrong, but the carburetor still overflowed. I replaced those parts I mentioned. After this, it still overflowed, so I took it to a dealer. He went through very much the same checkout, except more expertly, and adjusted a few things. The carburetor still overflows. Please give me some advice. Like I said, I'm going crazy; I mean I have not ridden my bike in a month.

Bob Wilkinson Northridge, Calif

The trouble you are experiencing with the carburetor on your machine is not a common fault on the Ace 90. However, the problem must be caused by one or more of the following circumstances-damaged needle seat, damaged float arrangement or incorrectly set fuel level. To check or reset the fuel level, first remove the carburetor from the engine, then remove the float chamber. Hold the carburetor inverted, then measure from the top edge of each float down to the float bowl mounting flange. If correctly set, this measurement will be 0.875 in. Make certain that both floats are set to this dimension. It requires the total buoyancy of both floats to apply sufficient pressure at the needle valve actuating tab to shut the fuel off before the chamber is full. If both floats are not level, correct this before proceeding. Also, if the floats are not set at the correct height, do not reset them by bending the float arms. Achieve the desired height by bending the needle valve actuating tab. If these points are attended to, there is no reason why the carburetor should flood.

Most Japanese carburetors are fitted with the delicate twin-float arrangement. It is important that the float chamber is carefully replaced to avoid damage. Many owners unwittingly cause damage, particularly on some of the twin carburetored engines on which one or the other of the carburetors is difficult to service. ■