THE SERVICE DEPARTMENT

JOHN DUNN

DISAPPOINTED

I am the disappointed owner of a 1966 Mark III Ducati, which I bought for $500 last spring. It had done 6000 miles and was in stock condition, except for a broken tachometer, and a 14-tooth sprocket on the final drive instead of the standard 18 teeth.

After the motorcycle hit a station wagon, it was repaired by a Chicago dealer. When it was returned, I fitted a stock sprocket, and it ran fine for about a month, when a valve-like ticking turned out to be the piston hitting the valves due to rod bearing failure. Again it went to the dealer, this time for an engine rebuild and a complete checkout. With new bearings, piston, valves and rings, it ran fine for a week or two.

I was told that plug trouble was normal during break-in, but after 300 or 400 miles of careful riding, plugs still fouled every 20 to 50 miles. I used No. 7 plugs, which kept fouling, even though I was careful not to lug the bike. Black, dry deposits formed on the plugs. Opinions on the trouble varied from oil fouling to excessively rich mixture. The dealer said that I wasn’t running the engine fast enough, and that it was unhealthy to ride it under 6000 rpm, but the engine seemed to “flat-out” far below maximum rpm.

Also, the engine was unusually touchy after break-in; it would not run at all with an air cleaner, and refused to run above 4000 to 5000 rpm with the megaphone. Then the clutch cable broke, and my Ducati hasn’t been used since.

Unless I find a solution, I plan to sell the bike. But, as an engineering student, I admire the Ducati as a machine and would like to keep it-if it was reliable.

Is my problem bad service, a bad bike, or is this type of trouble normal for a used Mark III Ducati?

Penn Clissold Coral Gables, Fla.

I very much doubt that your problem is caused by over-oiling. The fact that the engine refuses to run with the air cleaner attached indicates carburetor malfunction.

Remove and check the carburetor for correct jet, needle and throttle valve sizes. Also check that the fuel level is correct and that the float chamber needle is fully shutting off the fuel supply.

Your letter indicates that the engine is running excessively rich. If this is so, drain the lube oil as it is sure to contain too much gasoline. Does the exhaust tend to smoke? If the smoke is blue, this indicates oil burning. If the smoke is black, this shows the mixture is very rich.

TOTAL LOSS IGNITION

Pertaining to a four-stroke 50or 90-cc engine: Does eliminating the magneto or alternator and running the bike off a total loss ignition system give better performance? What advantage does a total loss system have in a racing engine?

Roger Clare Prescott, Mich.

Generating sufficient electricity for ignition purposes does rob the engine of some useful power. Though a high tension coil is required with either an alternator or magneto, the battery can be eliminated. This can result in some saving in total weight. Also, a regular battery is not too rehable with respect to continuous high frequency vibration, which is usually present on a high rpm racing motorcycle. A reliable magneto does take some beating for efficiency and dependability. Many standard alternators can be converted to supply ignition needs only. If a good magneto or alternator is not available for the particular machine in question, the total loss ignition system can be employed with reasonable reliability, providing the battery is mounted in a suitable manner that will guard against internal breakage from vibration. Care should also be excercised with respect to the routing of battery cables and connections, as they also are subject to vibration damage.

Some readers probably are not fully aware of what the term “total loss ignition” means. The components used are a contact breakers assembly, condenser, high tension coil and a battery. The battery, previously charged, supplies the electricity required for ignition. There is no provision on the machine for recharging the battery. When the battery is discharged, the ignition will cease to function. On small motorcycle engines the coil uses from 1 to 1.5 amperes per hour at maximum operating speed. Although a 10 ampere/hour battery theoretically will deliver 1 ampere for 10 hours, it is best in racing practice to halve or even quarter this performance.

(Continued on page 14)

THE TWIST

I own a 1966 Honda Scrambler and have had numerous crack-ups in the hills. I soon noticed that the top of the left fork, where the crown bolts on, was farther forward than the right. I assumed that the crown was bent, for they do bend easily. However, the installation of a new one did not remedy the situation. The left fork was still farther forward than the right.

This makes my handlebars crooked and my headlamp point off to the right. How can I remedy this situation? How can I tell if a fork itself is bent?

Terry Jones Long Beach, Calif.

It is quite possible the front forks on your machine are only twisted. This can be rectified. Loosen the fork tube pinch bolts, that are located in the bottom fork crown, and the top filler plugs. Then, while holding the front wheel between your knees, pull the handlebars around until they are at right angles to the front wheel. Then retighten the pinch bolts and filler plugs. Sometimes it is best to have these partially tightened before trying to align things.

If the front end will not respond to this treatment, and the top crown and handlebars keep springing back to an incorrectly aligned position, it is almost certain that one or more of the components in the front end are bent. First check the front wheel spindle. If this is okay, remove both fork legs complete and check that the main tubes are straight. To check these thoroughly, it is best to dismantle each fork leg completely. Place the main tubes between fixed V blocks, rotate them and check for run out with a dial indicator. If the tubes are not badly bent, they can be straightened in a small fly or hydraulic press. The top and bottom fork crowns can easily be checked by installing the straightened fork legs with the fork covers removed. Any misalignment will easily be seen. If the fork crowns are not badly twisted, they can be realigned cold with a large crescent wrench. It sometimes takes a little patience to obtain the desired result.

Most telescopic type forks will have a tendency to twist when ridden hard over a rough terrain. A good remedy for this is to construct a strong brace that ties both bottom fork sliders together.

HONDA PEP-UP

I am modifying my 1967 Honda CL 160.1 don’t wish to use a big bore kit, but I am thinking of adding horsepower by installing oversize intake valves, 22-mm carburetors, and a Harman and Collins track and street grind cam What will this do to the power output? Should I replace my stock valve springs with racing springs? I read that one man put 305 valves and 250 pistons into a 160-cc Honda. How much trouble would this be, and is it feasible?

W.R. Baldwin Kingsville, Tex.

The modifications you outline will improve volumetric efficiency (breathing ability) mainly at the upper end of the speed range. Use the valve springs recommended by the camshaft manufacturer, and make sure they are installed at the correct set height with the valve closed, and that they do not become coil bound (fully compressed) on full lift.

I have heard that a 250 Honda piston has been employed to increase the displacement of the 160. Apparently the 160 cylinder is bored to accept the 250 cylinder liner. Also, the crankcase mouth has to be enlarged to receive the larger diameter cylinder spigot. I have no first hand experience with this modification, and would appreciate the detailed observations of anyone who has.

View Full Issue

View Full Issue

More From This Issue

-

Round Up

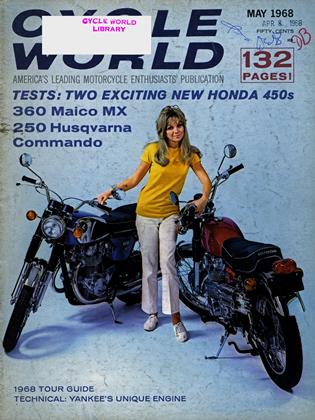

May 1968 By Joe Parkhurst -

Letters

LettersLetters

May 1968 -

The Scene

May 1968 By Ivan J. Wagar -

Ruin To Record

Ruin To RecordOut of the Rubble of World War Ii Came the Nsu Twin of Wilhelm Herz — the First Motorcycle To Break 200

May 1968 By Richard C. Renstrom -

Fiction

FictionThe Pickup

May 1968 By Robert Ricci -

Houston National

Houston NationalHouston National

May 1968 By Bruce Cox