THE SERVICE DEPARTMENT

JOHN DUNN

DON’T FIDDLE

Every big bike owner I’ve talked to recently has heard the old adage, “There’s no substitute for cubic inches,” and they all believe it. Ever since I started talking about buying a Suzuki X-6, I’ve been hearing statements like this:

“A motorcycle usually isn’t in the best state of tune all the time; with a big bike you can run out of tune and still have plenty of power. If you don’t keep a little bike tuned razor sharp, you don’t get anything.”

I’ve ridden an X-6 and was impressed with its ability to move my 195 pounds down the road quickly. It seems to have all the power I’ll ever really need, especially since most of my riding would be around the city with an occasional blast down a twisty country road. But since I’m not much of a mechanic, 1 can’t help wonder if what my friends say is true.

When a high-performance bike in the 250cc-350cc class is tuned, does it hold that edge for some time, or does the power fall off unless you’re constantly fiddling with the carburetors? If run a bit out of tune, would a bike like the Hustler produce enough power to cope with highspeed traffic? And just what is involved in tuning a two-stroke engine, anyway?

Even the fastest 250s aren’t meant to be as well adapted for touring as a BMW or a Harley FLH. But how would a bike like the Hustler respond to cross-country cruising over hundreds or thousands of miles? Could it haul a fellow my size that far at standard speed limits — 60, 70, 75 mph? Or would the limited displacement force a rider to settle for a lower speed to prevent the engine from chewing its insides out?

I realize all this talk about tuning is relative, and depends on the actual situation. But I’d appreciate a few general comments on the subject.

Jim Quinn Chicago, III.

The modern high performance lightweight is not that critical and providing it receives normal routine maintenance, it will perform quite satisfactorily. It will not be necessary to be “constantly fiddling with the carburetors” or anything else. Keeping a two-stroke in proper tune is no more involved than the four-stroke; in fact, there are fewer things to attend to.

The X-6 Hustler is very capable of the high speed long distance touring to which you refer. Although the 250 will be operating at a higher engine speed in relation to road speed than the larger capacity machine, it will not be subjected to any more stress due to its lighter rotational and reciprocating mass combined with a shorter working stroke.

(Continued on page 20)

We would like to stress that most motorcycles will run better longer if left to themselves; they don’t take kindly to the unsure probings of amateur mechanics, but thrive on professional maintenance, of the same sort you’d give a good car.

KANGAROO HOP-UP

Thought I might drop you a line from Kangaroo Land, as I’ve been reading your magazine for quite a few years now, and I think it’s the greatest.

I’m the proud owner of a Yamaha YDS-3, which I will be entering in competition shortly. Could you possibly give me a few ideas on how I could get more speed from my cycle (as in Australia “hot bits” are as scarce as hen’s teeth)?

Keith Woodings Brisbane, Australia

It is possible to obtain from Yamaha all the necessary parts to convert your YDS-3 for either scrambles or road racing competition. However, you could convert your existing engine components by carrying out the following modifications.

Reduce cylinder head volume to approximately lOcc. Measuring from the top of the cylinder bore, obtain the following port dimensions: to the top of the intake port 61mm., to the bottom 84mm. To the top of the exhaust port 27mm, to the bottom 50mm. The top edge of the transfer ports is angled so that two measurements are given. To the highest edge of transfer port, 37.5mm. To the lower end of the top edge of the transfer 39.5mm. The bottom measurement for the transfer remains the same as standard. If the machine is to be used for scrambles, the standard piston can be used. A special piston with one piston ring is available for road racing. Piston clearance at the skirt should be between 0.055mm and 0.06mm (.0022" to .0024"). A racing, expansion type exhaust system is available. The standard carburetor can be used for scrambling. A larger MIKUNI 276 carburetor is available for road racing. When the larger carburetor is employed, it is necessary to modify the standard cylinder barrel or fit the TD1B cylinder. There is a magneto available to replace the generator. TD1B clutch, primary drive and gearbox internals can be installed without any difficulty. Use a B-10EN spark plug instead of the standard B-77HC. Remove the oil pump and use a fuel/oil mixture of between 12 to 1 and 16 to 1. For scrambling, fit a larger air cleaner to insure adequate breathing.

HE'S BAFFLED

I own a Honda 160 with crossover pipes. I took my old baffles, cut the middles out, and welded the ends together. Now it runs lousy. It won’t do over 55 and it cuts out badly at peak rpm in each gear. But it runs fine when the baffles are out. The firm that sells the pipes doesn’t sell any form of muffler to go with them.

I’m getting awfully fed up, and I’m sure I’m not alone. I have tuned it richer and leaner, but nothing helps.

Do you have any suggestions on how to tune it with the baffles in, or any way I can keep it legal without any loss of performance?

Larry Lange Granada Hills, Calif.

The safest way for you to solve this problem would be to adapt the CL160 exhaust system to your machine, or just use the CL160 muffler with your pipes. The complete system would be the best bet, because it was designed specifically for the 160 engine. And while it is quiet and legal, it gives high power output.

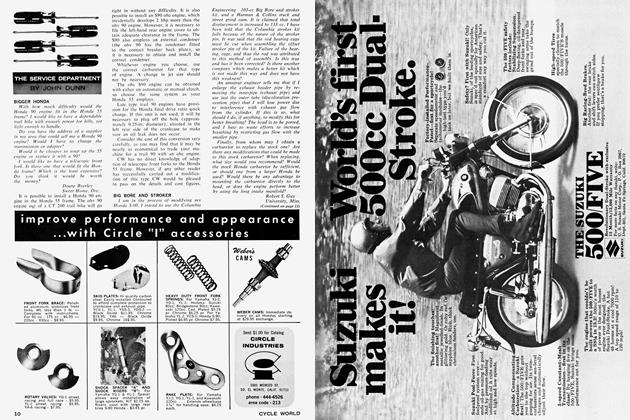

HEAVY HUSTLER

I just purchased my first motorcycle, an X-6 Hustler. Thanks to your very fine road tests I was able to decide exactly which machine would suit me the most. Within my price bracket, the Hustler seemed to fill the bill perfectly and I am delighted with the bike. So complete were your tests that I understood the peculiarities of this motorcycle before even getting on it, and 1 felt like an “old pro” during that first ride home. When I think of what I might have wound up with, were it not for your excellent magazine, it makes me realize what a fine service you are performing for the growing motorcycle industry.

Nothing is perfect, however, and l do have one problem which I hope you can help me with. I am unable to obtain speeds in excess of 90 mph. 1 may be wrong, but l don’t think the engine is out of tune, as it runs so strongly from 0 to 90. I have run the “Hustler” against much larger bikes and just walked all over them in acceleration runs. Three times 1 have complained to the dealer, who seems to be unable to do anything about it. He just argues that it must not be fully broken in. However, the bike has about 2,500 miles on it and the last 1,500 we’ve put on with “spirited driving,” to say the least. I can wind out very strongly in 5th gear, but when I hit 6th, the bike acts as if the load is just too great and rpms begin to drop rapidly until I am back down to 60 or 70. I tip the scales at 204 lbs., so maybe 1 am just too heavy for such a small engine, even the X-6. 1 feel if 1 were to go to a slightly larger rear sprocket l may not only improve acceleration but top speed as well, as a larger sprocket should allow 6th gear to wind on out. The trouble is, 1 am not sure I’m right about this, and even if 1 am, I wouldn’t know how much bigger to go on the sprocket or where to obtain it. I certainly would appreciate your technical assistance in this matter.

Robert Bush Houston, Tex.

Most of the Japanese machines appear to be geared for maximum speed with a light weight rider. With your above average weight, it will definitely be necessary to pull a lower gear to obtain maximum performance in 6th gear. I suggest you try a rear wheel sprocket with two more teeth than the one now fitted. Contact your nearest Suzuki dealer regarding the availability of alternative rear wheel sprockets, or write Tab-Loc, a regular CYCLE WORLD advertiser.

(Continued on page 22)

TORQUE TALK

In your magazine, advice is frequently given regarding the optimum length of exhaust and intake plumbing. In the case of a BSA 650, you advise that the length from spray bar to inlet valve is 7V2 inches and the exhaust be 39V2 inches long. Are these lengths determined by some formula, or are they experimental?

I would also like to know whether or not there is a method for designing an expansion chamber for a particular machine.

I would appreciate a reply to these questions, as I am planning on building up a trials machine, but would rather design it myself, as it would be much more beneficial than merely buying a bunch of bolt on “goodies.”

David A. Crosby Ann Arbor, Mich.

There are theoretical methods for designing exhaust and intake pipe configurations. The theory applied is based on the research carried out by several engineers and companies during the last half century. However, some of their findings have proved to be very conflicting, leaving certain aspects open for speculative evaluation by the individual. Even within the technical staff of CYCLE WORLD there is a conflict of opinions with respect to some of the minor conclusions, that make it virtually impossible to lay down a specific formula to follow.

In the main, there is a generally accepted line of approach which provides a reasonably sound basis for initial design. It is then necessary to carry out a series of instrumented tests to finalize the system for optimum results.

Therefore, any calculated lengths given in this (or any other) publication can only be considered as being approximate. Contrary to your opening remark, we very rarely give suggested exhaust and intake arrangement configurations, because in most cases the reader inquiring does not give sufficient information regarding the particular engine in question. We are quite willing to give advice and suggested dimensions, providing we know the effective valve timing (actual valve timing, taken with the normal running tappet clearance), the engine speed, where maximum effect is desired and the type of use the machine is to get.

The CYCLE WORLD Technical Manual gives some useful information on this subject in the section entitled “Ram Charging” and also gives a similar method of approach to two-cycle expansion chamber design and theory in the section entitled “Two-stroke exhaust tuning.”

However, you do not want a racing type exhaust on a trials machine. In fact, the least racy system possible would be your best bet; racing systems give high power output over a narrow rpm range, which is usually at high engine speed. For trials, where good low speed torque is required, it is more desirable to have a very wide, flat power range. Often a heavily baffled muffler will help to spread the power and work in your favor.

HOMEMADE WIGGLER

I am one of those persons who enjoys motorcycling, but didn’t have the cash to pay for one. As a result, several of us in our community built our own machines, using chain saw engines, scrap iron, 4:00x8 wheels and all the creativeness and ingenuity we could muster. The satisfaction of building our own machines was great. In fact, 1 plan to build my next machine. These worked fine on our ranches, but when we took to the road, new problems came up, mainly steering. My machine has a very bad steering problem which still haunts me.

At 10 mph and above, if 1 hit a bump, the front fork will go into a violent shimmy and will not quit until I come to almost a complete stop. Then 1 can resume speed. At any speed, if I jerk the handlebars, it will shimmy — though at slow speeds the shimmy grows smaller and quits quite rapidly.

If possible, I want to solve this problem, or at least prevent it from showing up in my next machine. Could you please recommend a book with information on steering geometry, so that I can design my machine properly?

I haven’t been able to get anything from any public library or even our W.S.U. Tech library, and 1 felt CW was the best to come to for help.

(Continued on page 24)

James Putnam

Pullman, Washington

By creating your own machine you probably enjoy motorcycling more than many of the owners who were fortunate enough to just go out and buy one. The problems you are experiencing in the handling department could be caused by several aspects directly related to basic design. Before starting on your new machine, it is essential that you study the theory of motorcycle frame design, paying particular attention to rigidity, direction of applied forces, as well as steering geometry.

For a person with limited equipment, a frame of triangular construction would offer a strong, easy-to-build configuration. Before constructing a frame, it is good practice to first make a simple assembly jig so that steering head angle, rear wheel position and alignment can be maintained. First, provide a level base from which to work. A flat, wooden surface would suit your purpose, and with the aid of a square and plumb line, this would ensure a fairly accurate basis for further construction. Mark a center line down the platform and lay out all the measurements related to head, wheel spindle position etc., along it. As an aid to ensuring that the chosen head angle is maintained, secure a tube to the base plate on the center line, at the same angle as the intended head angle, making sure that it is in vertical alignment by using the plumb line. It is now possible to position the steering head on the tube at the chosen height. The rear fork ends can be positioned by brackets in a similar way; then the frame tubes can be welded to these without worry about alignment.

A very good book that explains the basic design considerations of trail, head angle, weight distribution, wheel base, and in addition, evaluates various methods of construction, is “Motorcycle Engineering,” by Phil Irving. There is also an article on frames in the CYCLE WORLD Technical Manual. Both of these publications may be purchased through CW.

If you have any further queries, we will do our best to answer them.

RING-DING-PING

I am an Industrial Arts and Driver Education teacher and an avid motorcycle enthusiast. After yearning for a cycle most of my life, my wife finally got me one (a 250cc Yamaha Big Bear) as a college graduation present this Spring.

I would like to know if you can help me in finding out why I get what sounds like pinging when accelerating between 50 and 70 mph in 5th gear. I have tried premium gas, though the book only calls for 72 octane or better. The ignition timing is set with the mark on the rotor at the end of the crankshaft, right at the little pointer which l assume to be the correct reference point (the screw holding it has factory seeding dope on it).

Mike Greiner Galesburg, Michigan

The pinging sound to which you refer may be no more than something rattling on the machine, caused by vibration at the speed and load mentioned. On the other hand, it may be an indication that all is not well in the engine department. Preignition can be caused by several adverse operating conditions, and if allowed to continue, may result in serious engine damage. Recheck the ignition timing; make sure that the correct grade of spark plugs are fitted; also clean and adjust the carburetor and fuel supply system. A lean mixture or partially blocked passages would lead to overheating and thus preignition

Unusual carbon deposits, or the protruding portion of a cylinder head gasket, could produce a local hot spot in the combustion chamber and again cause preignition. A tight piston or one with small areas of close running clearance (high spots) will result in a general increase in engine operating temperatures which again will cause similar symptoms to occur.

TRIUMPH CUB VALVES

In the August, 1966 issue of CYCLE WORLD, you published the complaint of a '60 Triumph Cub owner who is bothered by noisy valves. 1 owned a cub of the same vintage and was similarly concerned.

(Continued on page 26)

The problem is simply one of a lack of oil to the rocker arms.

As you are no doubt aware, the rocker arms receive oil from the scavenge pump. The return oil line is crimped closed in the oil tank and is pierced an inch or so from the end. The size of this opening determines the back pressure on the return line, and, hence, the pressure on the supply to the rocker boxes. The “fix" 1 selected was to fit a spring steel clip over a portion of the pierced opening in the line. This opening is easily accessible through the oil tank filler port.

One must be careful not to divert too much oil to the rocker arms and cause the oil level in the tank to fall below the pickup opening. A compromise is quite easily obtained.

With proper lubrication, the valve operating mechanism is very quiet and rarely needs adjustment.

W. G. Gottenberg Boulder, Colorado

You have a good point here, so we have included your letter for the benefit of Turkey Foster or any other reader that may be having similar problems with his Tiger Cub.

Restricting the scavenge flow to the oil tank will certainly increase the oil flow to the top end, but as Mr. Gottenberg has pointed out, great care must be exercised to ensure that the return feed to the oil tank is not over-restricted, as this would result in a severe drop of the oil level in the oil tank, indicating that the crankcase was not being scavenged properly. After making any modification, make sure that the proper level is being maintained in the oil tank.

At anytime a rider desires an extra amount of oil at the valve gear for a short period, especially when starting from cold, it is possible to momentarily block off the return with one’s finger.

SPEEDO VERSUS TACH

/ own a 1965 Honda CB72 with around 2,000 miles on it. The rated top speed is 98 mph, but 1 am lucky if I get it up to 80-85 mph. Even at this speed, the tach is running about 8 or 9 grand. Once, when 1 came to a small hill, 1 got it up to 90 mph. But the tach was about 500 rpm past the “red line!" 1 was wondering if this could be due to valve float.

Wayne Jacobson Greendale, Wise.

The trouble you are experiencing has nothing to do with “valve float.” However, if you have lowered the overall gear ratio of the machine by fitting alternative sprockets this would result in a lower road speed (mph) being observed at maximum engine speed (rpm). If you have not altered the gearing, there is something wrong with the tachometer or speedometer, so have the instrument checked by your dealer.

With standard gearing, a CB72 should do 87 mph @ 8,000 rpm in fourth gear.

450 CARBS

I have a 450 Honda and think it is the greatest. 1 took it back for the 1,000-mile check and since then have had it in three other shops. My trouble is it sputters if / open it up fast for a getaway. No one seems to be able to cure this. After l get up to 60 mph, it smoothes right out and will do over a hundred very easily. Can you suggest where I can get my machine fixed or what / can do in order to have smooth acceleration?

Robert H. McDaniel Reseda, Calif.

Unfortunately, the trouble you experience with your Honda 450 is not uncommon. The sputtering or misfiring that occurs when the throttle is snapped open at low speed is apparently due to lack of sufficient fuel supply, caused by a malfunction of the carburetors. To my knowledge, Honda has not yet come up with a satisfactory answer. Of the various methods tried, decreasing the diameter of the throttle needle by approximately 0.008" seems to produce the best results. Employing methods of this type should only be considered as a temporary measure until the factory comes up with a permanent solution.

Concerning such matters, we would very much welcome the comments of the factory or their agents concerned, advising us of their efforts to overcome problems that are persistent in any individual make or model.

LATER WITH THE LIGHT

Using a timing light to test for proper ignition advance on my S90, 1 noticed that the stator reference mark would always be from one to six degrees past the second of two reference marks, that the rotor should be between. At idle, the “F” mark and stator were right on the money. Please suggest a remedy for this as it is probably hurting at the top end.

Joseph A. Puccio Houston, Texas

It would appear that the ignition timing on your S90 is too far advanced, due to a malfunction of the auto advance mechanism. The initial timing which is 5 degrees and is shown as “F” on the alternator rotor should not be checked with the engine running using a timing light. Even with the engine only idling, the advance mechanism will have started to operate and this will give a false indication of initial advance.

The initial timing should be set by turning the engine over by hand and mark “F” should coincide with the mark on the stator when the contact breaker points are just beginning to open. Only when this has been done should the total advance be checked with the timing lights. Then if the mark on the stator does not come between the two marks on the rotor, this condition definitely indicates that there is something wrong with the automatic advance mechanism. To correct this fault it will be necessary to fit a new advance mechanism or have the existing one checked by an expert. Note: Before checking the ignition timing, first check the points gap and readjust the timing chain. ■