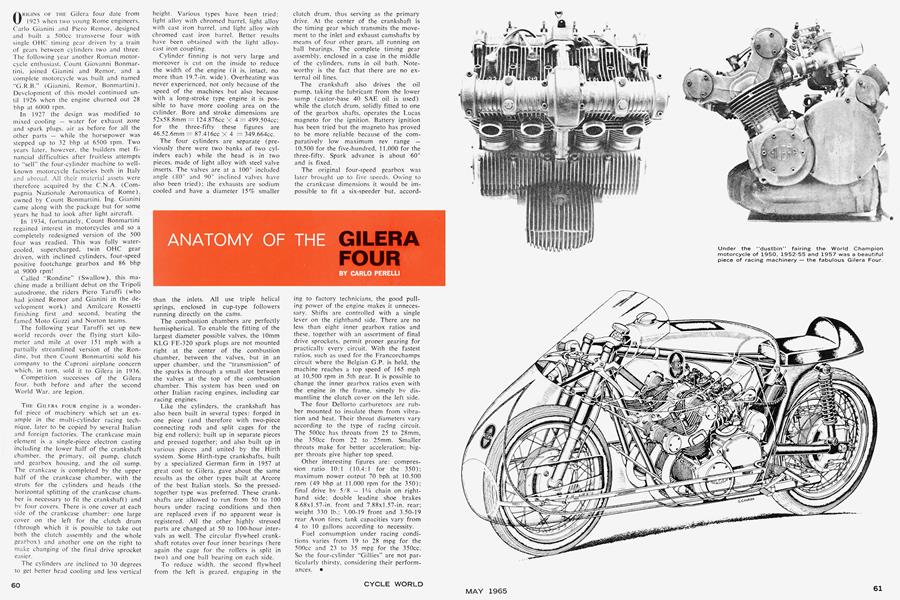

ANATOMY OF THE GILERA FOUR

CARLO PERELLI

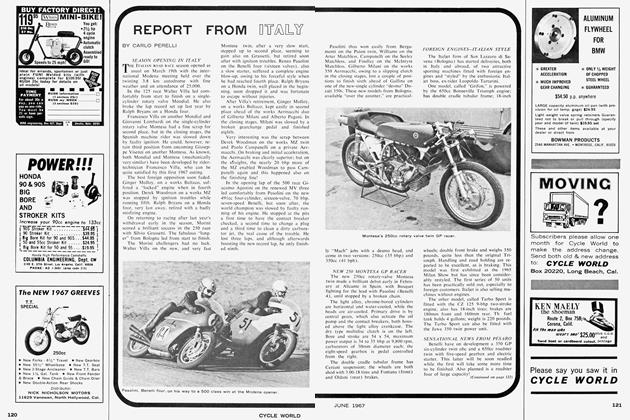

ORIGINS OF THE Gilera four date from 1923 when two young Rome engineers, Carlo Gianini and Piero Remor, designed and built a 500cc transverse four with single OHC timing gear driven by a train of gears between cylinders two and three. The following year another Roman motorcycle enthusiast, Count Giovanni Bonmartini, joined Gianini and Remor, and a complete motorcycle was built and named “G.R.B.” (Gianini, Remor, Bonmartini). Development of this model continued until 1926 when the engine churned out 28 bhp at 6000 rpm.

In 1927 the design was modified to mixed cooling — water for exhaust zone and spark plugs, air as before for all the other parts — while the horsepower was stepped up to 32 bhp at 6500 rpm. Two years later, however, the builders met financial difficulties after fruitless attempts to “sell” the four-cylinder machine to wellknown motorcycle factories both in Italy and abroad. All their material assets were therefore acquired by the C.N.A. (Compagnia Nazionale Aeronáutica of Rome), owned by Count Bonmartini. Ing. Gianini came along with the package but for some years he had to look after light aircraft.

In 1934, fortunately, Count Bonmartini regained interest in motorcycles and so a completely redesigned version of the 500 four was readied. This was fully watercooled, supercharged, twin OHC gear driven, with inclined cylinders, four-speed positive footchange gearbox and 86 bhp at 9000 rpm!

Called "Rondine” (Swallow), this machine made a brilliant debut on the Tripoli autodrome, the riders Piero Taruffi (who had joined Remor and Gianini in the development work) and Amilcare Rossetti finishing first and second, beating the famed Moto Guzzi and Norton teams.

The following year Taruffi set up new world records over the flying start kilometer and mile at over 151 mph with a partially streamlined version of the Rondine, but then Count Bonmartini sold his company to the Caproni airplane concern which, in turn, sold it to Gilera in 1936.

Competition successes of the Gilera four, both before and after the second World War. are legion.

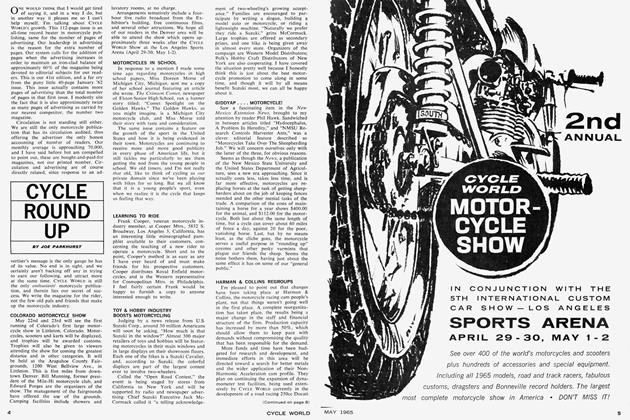

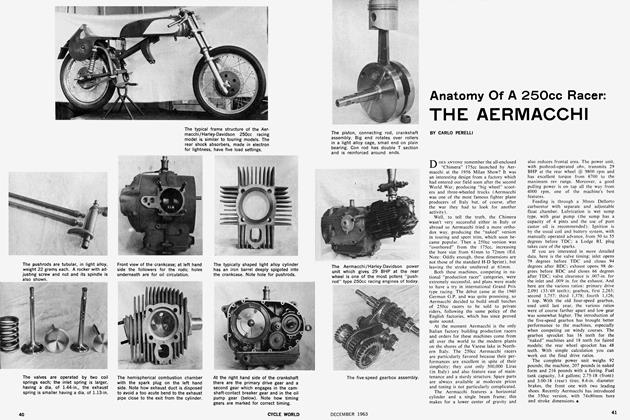

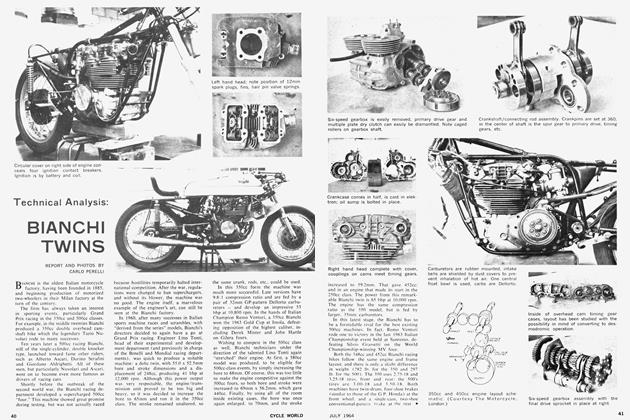

THE GILERA FOUR engine is a wonderful piece of machinery which set an example in the multi-cylinder racing technique. later to be copied by several Italian and foreign factories. The crankcase main element is a single-piece electron casting including the lower half of the crankshaft chamber, the primary, oil pump, clutch and gearbox housing, and the oil sump. The crankcase is completed by the upper half of the crankcase chamber, with the struts for the cylinders and heads (the horizontal splitting of the crankcase chamber is necessary to fit the crankshaft) and bv four covers. There is one cover at each side of the crankcase chamber: one large cover on the left for the clutch drum (through which it is possible to take out both the clutch assembly and the whole gearbox) and another one on the right to make changing of the final drive sprocket easier.

The cylinders are inclined to 30 degrees to get better head cooling and less vertical height. Various types have been tried: light alloy with chromed barrel, light alloy with cast iron barrel, and light alloy with chromed cast iron barrel. Better results have been obtained with the light alloycast iron coupling.

Cylinder finning is not very large and moreover is cut on the inside to reduce the width of the engine (it is, intact, no more than 19.7-in. wide). Overheating was never experienced, not only because of the speed of the machines but also because with a long-stroke type engine it is possible to have more cooling area on the cylinder. Bore and stroke dimensions are 52x58.8mm = 124.876cc X 4 = 499.504cc; for the three-fifty these figures are 46.52.6mm = 87.4! 6cc X 4 = 349.664cc.

The four cylinders are separate (previously there were two banks of two cylinders each) while the head is in two pieces, made of light alloy with steel valve inserts. The valves are at a 100° included angle (80° and 90° inclined valves have also been tried); the exhausts are sodium cooled and have a diameter 15% smaller than the inlets. All use triple helical springs, enclosed in cup-type followers running directly on the cams.

The combustion chambers are perfectly hemispherical. To enable the fitting of the largest diameter possible valves, the 10mm KLG FE-320 spark plugs are not mounted right at the center of the combustion chamber, between the valves, but in an upper chamber, and the “transmission” of the sparks is through a small slot between the valves at the top of the combustion chamber. This system has been used on other Italian racing engines, including car racing engines.

Like the cylinders, the crankshaft has also been built in several types: forged in one piece (and therefore with two-piece connecting rods and split cages for the big end rollers); built up in separate pieces and pressed together; and also built up in various pieces and united by the Hirth system. Some Hirth-type crankshafts, built by a specialized German firm in 1957 at great cost to Gilera, gave about the same results as the other types built at Arcore of the best Italian steels. So the pressedtogether type was preferred. These crankshafts are allowed to run from 50 to 100 hours under racing conditions and then are replaced even if no apparent wear is registered. All the other highly stressed parts are changed at 50 to 100-hour intervals as well. The circular flywheel crankshaft rotates over four inner bearings (here again the cage for the rollers is split in two) and one ball bearing on each side.

To reduce width, the second flywheel from the left is geared, engaging in the clutch drum, thus serving as the primary drive. At the center of the crankshaft is the timing gear which transmits the movement to the inlet and exhaust camshafts by means of four other gears, all running on ball bearings. The complete timing gear assembly, enclosed in a case in the middle of the cylinders, runs in oil bath. Noteworthy is the fact that there are no external oil lines.

The crankshaft also drives the oil pump, taking the lubricant from the lower sump (castor-base 40 SAE oil is used) while the clutch drum, solidly fitted to one of the gearbox shafts, operates the Lucas magneto for the ignition. Battery ignition has been tried but the magneto has proved to be more reliable because of the comparatively low maximum rev range — 10,500 for the five-hundred, 11,000 for the three-fifty. Spark advance is about 60° and is fixed.

The original four-speed gearbox was later brought up to five speeds. Owing xo the crankcase dimensions it would be impossible to fit a six-speeder but, according to factory technicians, the good pulling power of the engine makes it unnecessary. Shifts are controlled with a single lever on the righthand side. There are no less than eight inner gearbox ratios and these, together with an assortment of final drive sprockets, permit proper gearing for practically every circuit. With the fastest ratios, such as used for the Francorchamps circuit where the Belgian G.P. is held, the machine reaches a top speed of 165 mph at 10.500 rpm in 5th gear. It is possible to change the inner gearbox ratios even with the engine in the frame, simply by dismantling the clutch cover on the left side.

The four Dellorto carburetors are rubber mounted to insulate them from vibration and heat. Their throat diameters vary according to the type of racing circuit. The 500cc has throats from 25 to 28mm, the 350cc from 22 to 25mm. Smaller throats make for better acceleration; bigger throats give higher top speed.

Other interesting figures are: compression ratio 10:1 (10.4:1 for the 350);

maximum power output 70 bph at 10.500 rpm (49 bhp at 11.000 rpm for the 350); final drive by 5/8 — VA chain on righthand side; double leading shoe brakes 8.68x1.57-in. front and 7.88x1.57-in. rear; weight 330 lb.; 3.00-19 front and 3.50-19 rear Avon tires; tank capacities vary from 4 to 10 gallons according to necessity.

Fuel consumption under racing conditions varies from 19 to 28 mpg for the 500cc and 23 to 35 mpg for the 350cc. So the four-cylinder “Gillies” are not particularly thirsty, considering their performances.

View Full Issue

View Full Issue