POWER TRANSMISSION METHODS

GORDON H. JENNINGS

OFT STATED is the fact than the piston-type, internal combustion engine is a troublesome source of power. It must be set in motion by some outside power source (in the case of the motorcycle engine, usually a strong, right leg) before it will function at all and it must be turning fairly rapidly before it develops enough torque to overcome anything more than its own internal friction. Then, no sooner does it begin churning strongly than it reaches its operating limit, and within the relatively narrow speed range where it is comfortable, there is an even more narrow range in which it develops maximum power. With such a restricted usefulness, it is a small miracle that anyone ever had courage enough to believe that it would someday replace the horse — and there are those who are willing to argue that point even yet.

Part of the problem can be solved by employing a friction-type clutch, which can be slipped enough to get the vehicle underway without stalling its recalcitrant en gine. This device was not, however, used by Marcus, the inventor of the automobile; he merely persuaded the neighborhood strongman to hold the drive wheel clear of the street while the engine was being started, and this worthy simply dropped Marcus' creation with a helping forward shove when the inventor signalled his readiness to drive away. This scheme worked, but it presumed a great deal upon the continued willingness of one's fellows, especially those with the required muscle, and it is prob ably safe to say that the horse would still be very much in vogue if a better means had not been found. The means were found in the form of the clutch, which was borrowed from millers who used the things to start and stop their grist mills, and with that addition, the self-propelled vehicle took its first step toward being a practical mode of transportation.

With the one problem solved, another quickly devel oped. Due to the limited operating speed range of the engine, the vehicle was similarly limited. With a drive ratio sufficiently high to enable the engine to haul the vehicle into motion from rest, and to get it up and over any slight inclines, the engine would simply run out of breath at anything faster than a walk. Conversely, if the drive ratio was made low enough to permit a good brisk pace on the level (and speed was the thing, even then), it became next to impossible to get the vehicle in motion initially. The solution was obvious: to have two overall ratios; one for making starts and climbing hills; the other for canter ing along on the straight and level stretches. The engine could not be made to behave more agreeably, so the means were found to work around the difficulty.

Today, many things have changed, but engines are still unwilling to oblige their masters' whims, and the best means of making the confounded things work for us is a variable-speed transmission system. Now, of course, it is almost unthinkable to have as few as two drive ratios; three are properly regarded as a skimpy minimum, four are accepted as standard, five will make almost any motorcycle perform better and six or more are commonly found in all-out European road racing machines.

Everyone accepts the fact that more, and not fewer, drive ratios are desirable, but it is doubtful that the reasons behind the fact are very widely understood. The whole matter centers about the output characteristics of the engine and the performance that output can lend to whatever vehicle in which the engine is installed. At any given engine output (within the bounds of the conventional), a pair of ratios will do the basic job. Aerodynamic drag limits the ultimate top speed rather sharply, and not too much power multiplication is required to simply get the machine in motion, so with a modicum of engine flexibility, a pair of gears will cover the entire speed range. However, it must be appreciated that with a two-speed transmission acceleration will be very limited indeed.

An engine that is rated at 50 bhp develops but a fraction of that output at idle, and if it is overspeeded, the output once again drops to well below the maximum. Only while running at its peaking speed does it deliver maximum power. Thus, the motorcycle having a 50 bhp engine will, most of the time, be propelled by somewhat less than 50 bhp, the exact amount being determined by two important factors: first, the overall output characteristics of the engine, which may be seen in the shape of the power curve; and second, the number and staging of the transmission ratios. The final overall acceleration capability of the motorcycle will depend almost entirely on the mutual balancing of these factors.

In practical terms, this means that so long as we must manage with only four ratios, we are limited insofar as engine modifications are concerned. The engine's power curve must be relatively flat, so that after peaking in each gear, and shifting to the next, the power does not fall away too drastically with the drop in engine speed. To illustrate this, consider what would happen if we were to install a Honda 250cc, four-cylinder racing engine in a (for example) BSA Royal Star frame, using all of the BSA parts, including the transmission, but not the engine. On the basis of maximum rated power, it would appear that the installation of the smaller racing engine should improve the performance; but that would not be the case. Handicapped by the BSA's four, touring-staged ratios, the Honda would just stagger along most of the time, coughing and sputtering, and the performance would be far inferior to the same machine with its standard, nominally less powerful, engine. The same thing is true, although to a lesser extent, of bikes that have had their standard engines super-tuned. If the tuner goes too far, he may find that the engine is operating completely out of its effective speed range more often than not, and the bike's performance will suffer. This occurs because virtually every technique we may employ to raise an engine's power output at its peaking speed will also tend to reduce the output at the lower end of the engine speed range. Therefore, if really radical engine modifications are contemplated, it will be necessary to make transmission changes as well.

This brings us to the subject of transmission ratio staging. In motorcycles intended for ordinary touring use, first and fourth gears are chosen to match touring requirements. That is to say, the first-gear ratio is made high enough to provide the power multiplication needed to get underway on the steepest hill the machine is likely to encounter, with the heaviest load it is likely to be asked to carry. Fourth gear, the top drive ratio, will be chosen, usually, to give a three-way balance between top-speed, top-gear acceleration, and a ratio of rpm/mph that will not result in the engine being flogged to death at whatever steady cruising speed may be envisioned. These factors set the upper and lower ratios, and second and third, the intermediate gears, are in most instances staged evenly in between. Sometimes, however, second and third gears may be nudged up nearer fourth to provide a sort of close-ratio gearing. This may reduce accelerating potential from a standing start, because of the large jump between first and second, but performance will usually be improved through middle and upper speed ranges.

Road racing motorcycles present an entirely different problem. Once away from the starting line, these machines seldom drop below 30 mph, and they can therefore be geared so that in first, the engine is just beginning to pull at that speed. Obviously, the rider will have to do a lot of clutch slipping to get underway cleanly, but he will be able to use all four gears to good effect once he gets rolling. Still, if a four-speed transmission is used, there will be limits to what may be done with the engine. If the engine is too highly tuned, and the power range is too drastically narrowed, the rider will find that he loses too many revolutions after each shift to keep the engine operating at its maximum and he will spend a lot of moments in frustration waiting for the engine to "come up on the cam." The answer here is a fiveor even six-speed transmission, as this would not only allow the engine to be held nearer its peaking speed, but would also permit, a more radical state of tune, as the rider would always be able to hold the engine speed within the required speed range. An extreme example of this can be seen in the recently developed 50cc GP racing motorcycle engines, which have an effective power range of not much more than 1000 rpm, and require 8, 10, and 12-speed transmissions to be usable at all. In effect, the rider simply holds the throttle wide open, the engine speed constant, and varies the bike's speed with the gear lever.

Broadly speaking, there is no substitute for additional transmission ratios; given more ratios, it is possible to have a motorcycle's engine working nearer its absolute maximum at all times and better performance must surely result. A good example of this is present in the YDS-2 Yamaha, which has an engine of not much better than average output, for its displacement, but possesses exceptional acceleration nonetheless. The reason? Its five-speed transmission. And, it follows that if the same bike had a six-speed transmission, performance would be better.

In light of this, one might logically ask why the motorcycle industry has settled on four-speed transmissions as a standard. The key word is "cost." Those extra gears and the added complications in the shifting mechanism that are necessary to get the added ratio or ratios are expensive, and it is easier and less costly to simply enlarge the engine's piston displacement. This, too, will improve performance — and it usually costs very little. Five-speed transmissions are a sign of efficiency, and they do help the machine that must be held to a displacement limit to satisfy racing rules, but by and large, just bunging out the cylinders has proven to be an equally satisfactory solution. In fact, it has been demonstrated that multispeed transmissions can be dispensed with altogether: "Big-inch" dragsters do very nicely with only one drive ratio, and they have quite a range of speed with more than an adequate rate of acceleration. Of course, all of this is accomplished with a fine disregard for overall efficiency and that is why we do not universally substitute piston displacement (which means torque) for multispeed transmissions.

Once the designer settles on the number of ratios circumstances will permit, there remains the task of providing a mechanism that will do the job well, and also do it reliably — which is not necessarily the same thing. In the past, many different layouts have been tried, including one unit in which there were no gears, but rather chains and sprockets (an efficient arrangement, but bulky and heavy). At present, however, design seems to have centered on two basic gear-train layouts; the all-indirect type, in which the drive passes through pairs of gears, from an input shaft across to an output shaft; and the direct-drive final gear type, which is most often used in touring motorcycles and in which input and output elements are locked together to give a direct drive for top gear. There are, as always seems to be the case, advantages and disadvantages inherent in both types.

If we assume that there will be a 2-percent power loss at each point of mesh, the all-indirect layout gives the best overall results, as it operates at 98-percent efficiency at all times. The direct-top layout, on the other hand, has one point of mesh where the power is taken to the layshaft, and another where it is transferred back up to the output shaft, which gives it an overall 4-percent loss in all of the intermediate gears. As applied to a straight-forward touring motorcycle, this is of little importance, because such machines are operated-in the direct, no-loss top gear most of the time. However, with today's highly tuned sports/touring motorcycles, there is a lot of time spent churning along in third, and sometimes second (to keep the engine turning fast enough to have some power on tap) and the all-indirect transmission is very attractive for this kind of service. Thus, the choice of basic layout is affected greatly by the uses to which the motorcycle wil be put.

Another advantage of the direct-top transmission is that the input and output shafts can be (and usually are) concentric, one inside the other, and chain-pull from the primary and final drives are largely mutually cancelling. This lightens the loads on the frame, and on the transmission mainshaft bearings. Here again, though, progress is changing the picture. When the engine and transmission are housed in a single casing, as is so often done now, primary chain loadings are absorbed within the casing and loads on the frame are reduced to those from the final drive. Even these may be eliminated by placing the rear-suspension pivot on the transmision casing, or on the same mounting plates. We are, then, left only with the higher bearing loadings, which may easily be accommodated by making the bearings slightly larger. This is, in practice, precisely what is done, and it is but one of the design solutions that is making the all-indirect layout ever more popular.

The only substantial disadvantage of the all-indirect transmission is that it is difficult to provide a really low, low-gear. The drive passes through only one set of gears, and to get a, for example, 3.0:1 reduction for first gear, it is necessary to have one very large gear on the output shaft. Because there are limits as to how small the input gear can be, the shafts have to be placed far apart and the gearbox grows in size as a result. Fortunately, a solution has been found for this, too : in modern all-indirect transmissions, hiost of the necessary reduction is done in the primary drive, and then to get useful third and top ratios, these gears are made, in effect, overdrives. Using once more the Yamaha 5-speed transmission as an example, we have first, second, and third as reduction gears, and fourth and fifth gears are overdrives. The primary drive reduction for this particular motorcycle is a high 3.25:1, and with a further reduction of 2.438:1 on the final drive, the transmission low-gear ratios need be only 2.5:1 to give an overall low-gear ratio of 19.8:1. If this transmission had the 1:1 top gear of the direct-drive type, the cruising gear ratio would be a stump-pulling 7:8:1, but in fact, the Yamaha's fifth gear is on 0.750 overdrive, and the overall ratio is 5.94:1.

We might mention at this point that the very high primary reduction ratio has one very useful side effect: the transmission runs at much less than engine speed and as the gears are revolving so slowly, churning losses are reduced. Also, the lower rotational speeds mean reduced gear-train inertia and smoother shifting. Of course, this is true of nearly all motorcycle transmissions, to a greater or lesser extent. The BMW has an engine-speed driven clutch and transmission, and it is notable for the "clunk" the gear engagement dogs produce with each shift.

The final advantage of the all-indirect, "cross-over" transmission is that the output sprocket is not hidden behind the clutch, and changes in final-drive gearing may be made relatively easily. It is possible to overcome this problem in the direct-top transmission, by taking the drive from the end of the shaft opposite the clutch, but it is almost never done. There is, as an exception, the Velocette, but in that layout, the output shaft extends through the center of the clutch and emerges outboard of that unit where the drive sprocket is exposed for quick changes. This is only possible, though, because of the narrowness of the Velocette's crankcase, which brings the primary drive back to the transmission along a line only slightly offset from the frame centerline. With a twin, such a layout would be impossible unless the drive were taken from the center of the crankshaft.

Methods of gear selection have been the subject of much experimentation, but this too has been reduced to two basic types. The most commonly used is the face-dog layout, in which the gears have teeth machined at their sides, and engagement is made by pulling either these gears, or straight engagement elements, sideways on the transmission shafts until the teeth mesh. Thus, by (in effect) locking appropriate sets of gears to each other, and/ or to the shafts, the various ratios are selected. Usually, two shifting forks, which move the sliding elements back and forth, are required. This brings us to the other basic shifting layout.

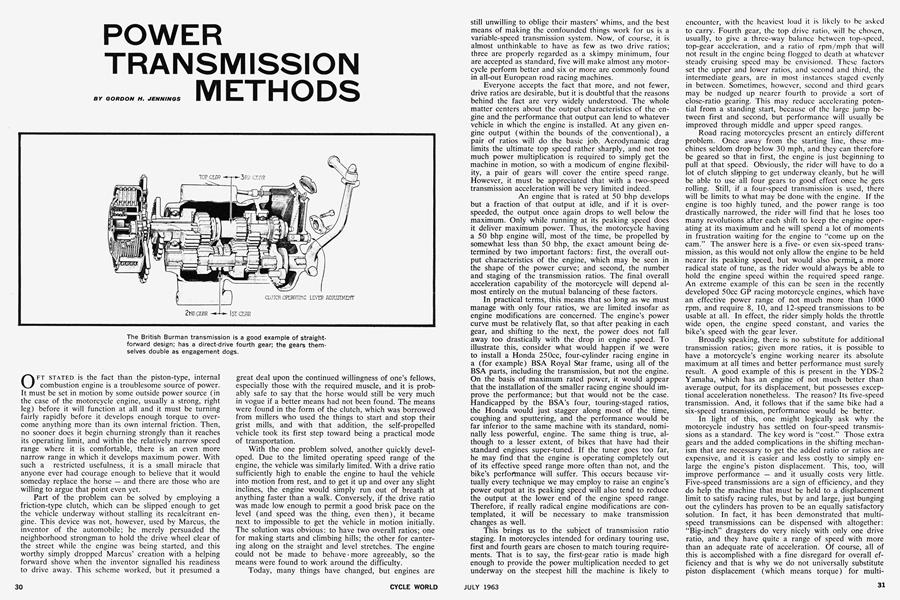

The Albion transmission, used in many British-made motorcycles, has only one set of shifting forks, and all changes are made by sliding a single group of moving elements right straight across. For first, face dogs engage; to select second, the sliding group moves the face dogs on the mainshaft out of engagement and internal splines on one of the countershaft gears are moved into mesh with a set of short splines on the countershaft itself; another set of short splines on the countershaft are engaged for third; and fourth is selected by a final set of face-dogs that lock together the input and output shafts. This layout has the prime and worthwhile advantage of simplicity, but unless a very heavy detent spring is used in the selector mechanism, the inertia of that big sliding cluster can create problems.

When the transmission is "stomp-shifted," as motorcycle transmissions often are, the sliding cluster is slammed across the shafts very fast, and it will try to keep going until it hits the end of the line. Friction and the detent mechanism will slow its progress, obviously, but there will be times when it goes right past the engagement the rider intended and stops in either a neutral position or even in the next gear. Hence, the need for an exceptionally strong detent, to "catch" the sliding cluster as it goes whizzing by. The end result of the shifting inertia and heavy detent action is to make the shifting feel a trifle heavy, and the rider will have the distinct impression that he is punching the gears into engagement against considerable odds.

Shifting inertia problems can arise in other transmission layouts as well. These have two separate shifting forks, which must be operated in proper sequence to bring the gears into correct engagement, and this sequence is provided by a cam-type device; either a drum or flat plate having slots that carry the shifting forks back and forth as the drum or plate rotate. The inertia of this drum, or plate, coupled with that of the forks and the transmission's sliding elements, can create exactly the same problems just described in the Albion layout, requiring the same solution and producing the same results. For shifting precision, the shifting mechanism's parts must be rigid, and to make them rigid (unless cost is no consideration) they must be heavy, and that means high inertia. Broadly speaking, the small-diameter drum has less inertia than a circular cam plate, but recent cam plates are only segments of circles, and are light enough to make inertia effects relatively less bothersome.

One of the more useful techniques employed to make gear engagement more certain is the trimming-back of every other tooth on the engagement dogs. This simply provides room for the dogs to move further into mesh, with a few degrees of rotation in one set of dogs, relative to the other, before final mesh is made. In short, it makes it possible for one set of dogs to snag the other as they are brought into mesh. Unless this technique is employed, it is necessary to allow several degrees of "lash." If the dogs were cut so that all of the teeth slid together without side clearance, it would be almost impossible to match their rotational speeds closely enough to make them slide into mesh when changing gears.

Unfortunately, there is little the private motorcycle owner can do about his Pride-and-Joy's transmission; at least, insofar as direct modifications are concerned. Cutting new gear sets is possible, and there are numerous shops around the country that have the necessary equipment, but the price of a set of one-off gears would be, probably, about five times as high as the initial cost of the entire motorcycle. There is a way around this: most manufacturers have in stock sets of special-purpose gears for their products. Motorcycles that use the Albion transmission, in the larger sizes, are blessed with about a halfdozen alternative gear sets, ranging from touring and trials gears to ultra-close gearing for road racing. BSA, too, has alternative ratios for touring, scrambles and road racing. Approximately the same is true of Triumph, and all of the other motorcycle manufacturers. Of course, no one is going to try and sell you a set over the counter; these gears are made available as a sort of special service and it will be necessary to order them (probably all the way from the factory) and wait. They will no doubt be some time in coming and cost like fury when they arrive, but anyone who is serious about competition, or simply in having an especially brisk road machine, will definitely be needing them. This is, obviously, particularly true when extensive engine modifications are planned.

So much for the generalizations. Next month we will get down to those things over which the individual has some control: the care of drive chains, the selection of ratios for top speed and/or acceleration, some basic information on the relative efficiencies of gear and chain drive, how to compute gear ratios and to calculate rpm against mph, etc. Look for it.