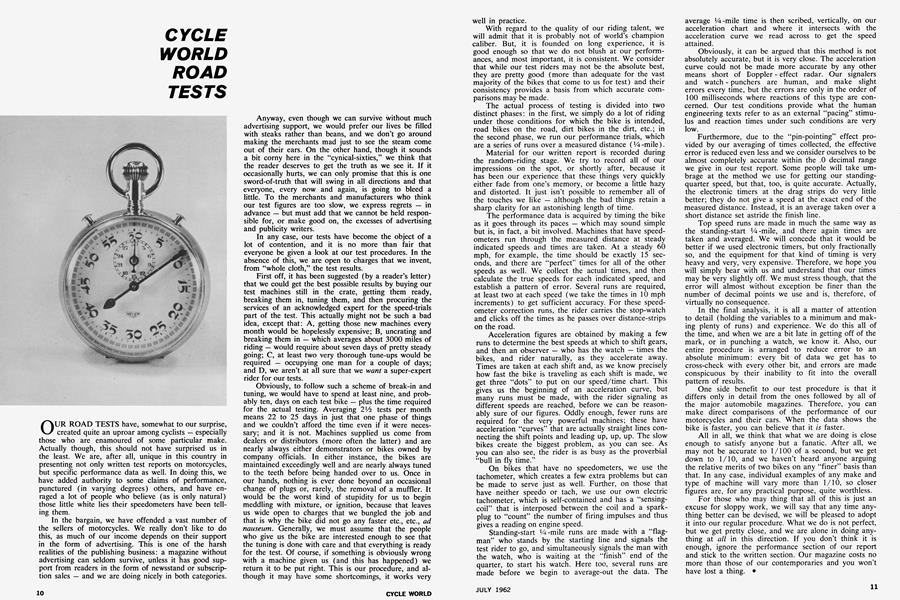

CYCLE WORLD ROAD TESTS

OUR ROAD TESTS have, somewhat to our surprise, created quite an uproar among cyclists — especially those who are enamoured of some particular make. Actually though, this should not have surprised us in the least. We are, after all, unique in this country in presenting not only written test reports on motorcycles, but specific performance data as well. In doing this, we have added authority to some claims of performance, punctured (in varying degrees) others, and have enraged a lot of people who believe (as is only natural) those little white lies their speedometers have been telling them.

In the bargain, we have offended a vast number of the sellers of motorcycles. We really don’t like to do this, as much of our income depends on their support in the form of advertising. This is one of the harsh realities of the publishing business: a magazine without advertising can seldom survive, unless it has good support from readers in the form of newsstand or subscription sales — and we are doing nicely in both categories. Anyway, even though we can survive without much advertising support, we would prefer our lives be filled with steaks rather than beans, and we don’t go around making the merchants mad just to see the steam come out of their ears. On the other hand, though it sounds a bit corny here in the “cynical-sixties,” we think that the reader deserves to get the truth as we see it. If it occasionally hurts, we can only promise that this is one sword-of-truth that will swing in all directions and that everyone, every now and again, is going to bleed a little. To the merchants and manufacturers who think our test figures are too slow, we express regrets — in advance — but must add that we cannot be held responsible for, or make good on, the excesses of advertising and publicity writers.

In any case, our tests have become the object of a lot of contention, and it is no more than fair that everyone be given a look at our test procedures. In the absence of this, we are open to charges that we invent, from “whole cloth,” the test results.

First off, it has been suggested (by a reader’s letter) that We could get the best possible results by buying our test machines still in the crate, getting them ready, breaking them in, tuning them, and then procuring the services of an acknowledged expert for the speed-trials part of the test. This actually might not be such a bad idea, except that: A, getting those new machines every month would be hopelessly expensive; B, uncrating and breaking them in — which averages about 3000 miles of riding — would require about seven days of pretty steady going; C, at least two very thorough tune-ups would be required — occupying one man for a couple of days; and D, we aren’t at all sure that we want a super-expert rider for our tests.

Obviously, to follow such a scheme of break-in and tuning, we would have to spend at least nine, and probably ten, days on each test bike — plus the time required for the actual testing. Averaging 2XA tests per month means 22 to 25 days in just that one phase of things and we couldn’t afford the time even if it were necessary; and it is not. Machines supplied us come from dealers or distributors (more often the latter) and are nearly always either demonstrators or bikes owned by company officials. In either instance, the bikes are maintained exceedingly well and are nearly always tuned to the teeth before being handed over to us. Once in our hands, nothing is ever done beyond an occasional change of plugs or, rarely, the removal of a muffler. It would be the worst kind of stupidity for us to begin meddling with mixture, or ignition, because that leaves us wide open to charges that we bungled the job and that is why the bike did not go any faster etc., etc., ad nauseum. Generally, we must assume that the people who give us the bike are interested enough to see that the tuning is done with care and that everything is ready for the test. Of course, if something is obviously wrong with a machine given us (and this has happened) we return it to be put right. This is our procedure, and although it may have some shortcomings, it works very well in practice.

With regard to the quality of our riding talent, we will admit that it is probably not of world’s champion caliber. But, it is founded on long experience, it is good enough so that we do not blush at our performances, and most important, it is consistent. We consider that while our test riders may not be the absolute best, they are pretty good (more than adequate for the vast majority of the bikes that come to us for test) and their consistency provides a basis from which accurate comparisons may be made.

The actual process of testing is divided into two distinct phases: in the first, we simply do a lot of riding under those conditions for which the bike is intended, road bikes on the road, dirt bikes in the dirt, etc.; in the second phase, we run our performance trials, which are a series of runs over a measured distance (Va-mile).

Material for our written report is recorded during the random-riding stage. We try to record all of our impressions on the spot, or shortly after, because it has been our experience that these things very quickly either fade from one’s memory, or become a little hazy and distorted. It just isn’t possible to remember all of the touches we like — although the bad things retain a sharp clarity for an astonishing length of time.

The performance data is acquired by timing the bike as it goes through its paces — which may sound simple but is, in fact, a bit involved. Machines that have speedometers run through the measured distance at steady indicated speeds and times are taken. At a steady 60 mph, for example, the time should be exactly 15 seconds, and there are “perfect” times for all of the other speeds as well. We collect the actual times, and then calculate the true speeds for each indicated speed, and establish a pattern of error. Several runs are required, at least two at each speed (we take the times in 10 mph increments) to get sufficient accuracy. For these speedometer correction runs, the rider carries the stop-watch and clicks off the times as he passes over distance-strips on the road.

Acceleration figures are obtained by making a few runs to determine the best speeds at which to shift gears, and then an observer — who has the watch — times the bikes, and rider naturally, as they accelerate away. Times are taken at each shift and, as we know precisely how fast the bike is traveling as each shift is made, we get three “dots” to put on our speed/time chart. This gives us the beginning of an acceleration curve, but many runs must be made, with the rider signaling as different speeds are reached, before we can be reasonably sure of our figures. Oddly enough, fewer runs are required for the very powerful machines; these have acceleration “curves” that are actually straight lines connecting the shift points and leading up, up, up. The slow bikes create the biggest problem, as you can see. As you can also see, the rider is as busy as the proverbial “bull in fly time.”

On bikes that have no speedometers, we use the tachometer, which creates a few extra problems but can be made to serve just as well. Further, on those that have neither speedo or tach, we use our own electric tachometer, which is self-contained and has a “sensingcoil” that is interposed between the coil and a sparkplug to “count” the number of firing impulses and thus gives a reading on engine speed.

Standing-start F^-mile runs are made with a “flagman” who stands by the starting line and signals the test rider to go, and simultaneously signals the man with the watch, who is waiting at the “finish” end of the quarter, to start his watch. Here too, several runs are made before we begin to average-out the data. The average VA -mile time is then scribed, vertically, on our acceleration chart and where it intersects with the acceleration curve we read across to get the speed attained.

Obviously, it can be argued that this method is not absolutely accurate, but it is very close. The acceleration curve could not be made more accurate by any other means short of Doppler - effect radar. Our signalers and watch - punchers are human, and make slight errors every time, but the errors are only in the order of 100 milliseconds where reactions of this type are concerned. Our test conditions provide what the human engineering texts refer to as an external “pacing” stimulus and reaction times under such conditions are very low.

Furthermore, due to the “pin-pointing” effect provided by our averaging of times collected, the effective error is reduced even less and we consider ourselves to be almost completely accurate within the .0 decimal range we give in our test report. Some people will take umbrage at the method we use for getting our standingquarter speed, but that, too, is quite accurate. Actually, the electronic timers at the drag strips do very little better; they do not give a speed at the exact end of the measured distance. Instead, it is an average taken over a short distance set astride the finish line.

Top speed runs are made in much the same way as the standing-start VA -mile, and there again times are taken and averaged. We will concede that it would be better if we used electronic timers, but only fractionally so, and the equipment for that kind of timing is very heavy and very, very expensive. Therefore, we hope you will simply bear with us and understand that our times may be very slightly off. We must stress though, that the error will almost without exception be finer than the number of decimal points we use and is, therefore, of virtually no consequence.

In the final analysis, it is all a matter of attention to detail (holding the variables to a minimum and making plenty of runs) and experience. We do this all of the time, and when we are a bit late in getting off of the mark, or in punching a watch, we know it. Also, our entire procedure is arranged to reduce error to an absolute minimum: every bit of data we get has to cross-check with every other bit, and errors are made conspicuous by their inability to fit into the overall pattern of results.

One side benefit to our test procedure is that it differs only in detail from the ones followed by all of the major automobile magazines. Therefore, you can make direct comparisons of the performance of our motorcycles and their cars. When the data shows the bike is faster, you can believe that it is faster.

All in all, we think that what we are doing is close enough to satisfy anyone but a fanatic. After all, we may not be accurate to 1/100 of a second, but we get down to 1/10, and we haven’t heard anyone arguing the relative merits of two bikes on any “finer” basis than that. In any case, individual examples of any make and type of machine will vary more than 1/10, so closer figures are, for any practical purpose, quite worthless.

For those who may thing that all of this is just an excuse for sloppy work, we will say that any time anything better can be devised, we will be pleased to adopt it into our regular procedure. What we do is not perfect, but we get pretty close, and we are alone in doing anything at all in this direction. If you don’t think it is enough, ignore the performance section of our report and stick to the written section. Our magazine costs no more than those of our contemporaries and you won’t have lost a thing.