THE ELEGANT SOLUTIONS

Getting more of what we need from motorcycle frames out of less material

September 1 2021 KEVIN CAMERONGetting more of what we need from motorcycle frames out of less material

September 1 2021 KEVIN CAMERONTHE ELEGANT SOLUTIONS

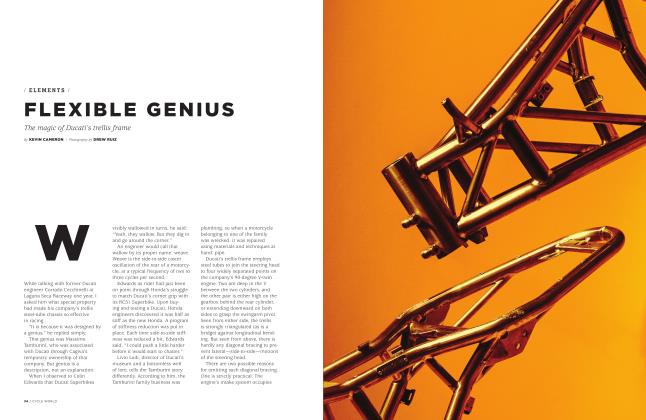

ELEMENTS

Getting more of what we need from motorcycle frames out of less material

KEVIN CAMERON

Early motorcycle frames were just the classic single-plane bicycle frame, but made of heavier tubing. They were a practical design for engines of low power and moderate vibration. As engines and rpm grew, chassis cracked, so the manufacturers just used heavier tubing on the next model. Meanwhile, like a piece of paper, the two-dimensional frame was a poor use of material if what you needed was structural stiffness in three dimensions.

A big step forward was Norton’s Featherbed twin-loop chassis of 1950, which resembled two single-plane chassis side by side, joined into a much stiffer three-dimensional box form by cross-members. Its steering head was well braced in all directions and its swingarm was strongly supported between the frame loops. Production versions weighed 45 pounds. This remained a strong influence in motorcycle chassis design for more than 30 years. It made better use of its material by placing its elements around a large internal volume, giving them increased leverage over the loads they carried.

When the early 1970s joined much more powerful engines to existing chassis designs the results were often unstable and unable to handle the loads from wider, grippier tires and disc brakes. Engineers were forced away from tradition and back to first principles: When we fly, we sit inside a large and very thinwalled tube. It is strong because it gains leverage over loads applied to it because of its large diameter.

The 1980s saw Norton’s boxy tube frame morph into Antonio Cobas’ lighter and stiffer twin beam chassis, which in Yamaha’s hands became the Deltabox of thin pressed aluminum. Why not a single larger beam, such as Kawasaki tried in its KR500 GP bike? The single large tube arching from the steering head and over the engine is light and stiff but interfered with service access.

As we have seen, the twin-beam concept is not the only path to success—Ducati’s triangulated steel multi-tube trellis chassis has been successful as well.

The principle of moving structure weight to the largest possible diameter continues to stand. We see it in the steady growth of telescopic fork tubes. The Gileras of 1950 had 32mm tubes, growing to around 35mm by 1974, and as the tire, suspension and brake revolutions of that difficult decade continued, tube diameter for powerful motorcycles has swelled to 42~50mm. Around 1989 came another revolution—the one that put the larger female fork tube at the top, where the greatest bending moment exists right below the lower fork crown. The inverted fork’s smaller inner tubes are now joined only by the front axle. Such vastly stiffer fork tubes give modern bikes their “right now” steering.

When a motorcycle sweeps through a bumpy corner leaned over, pavement irregularities tilt the front wheel—opposed only by the stiffness of its axle. That tilt causes the brake discs to knock the brake calipers’ pistons back in their bores, leaving you with a low lever or one that comes to the bar when you pull

By the mid-1990s front axles of powerful racebikes had grown from the 1 7mm-diameter solid designs of the early ’70s to 25mm or more. Because the new axles were hollow (material close to the centerline has almost no leverage over bending loads) and of larger diameter, they not only prevented brake pad knock-back, they were actually lighter than before.

Swingarms have received the same treatment. Through the 1950s, ’60s, and ’70s swingarms remained basically three pieces of pipe welded together with axle holders at the ends of the side beams. Early AMA Superbikes, based on Kawasaki’s Z1 and Suzuki’s GS series, needed help badly because such weak arms couldn’t keep the rear wheel stably in-plane. The first step was to weld in braces made of steel tubing, to keep the wheel from tilting. Lots of fussy welds on numerous tubes made a long job so in time the structure was simplified into first a sheetaluminum box and then simplified again into thin-walled castings assembled by one or two welds.

This is complicated by the fact that motorcyclists have a range of tastes and preferences. Some Ducati riders resist the passing of the steel tube trellis frame. Older riders may prefer the open look of historic bikes such as the original Triumph 650 Bonneville. Fortunately, the work of developing the high-performance chassis of the present day has revealed the levels of stiffness required for different applications, and such levels can now be met in more than one possible way.

Who can say what the future will bring? When MotoGP engineers are curious as to what added stiffness here or there might accomplish, they now bond plies of carbon fabric onto the area of interest. Is this just a Band-Aid or could it be a trend toward future all-carbon chassis?

View Full Issue

View Full Issue

More From This Issue

-

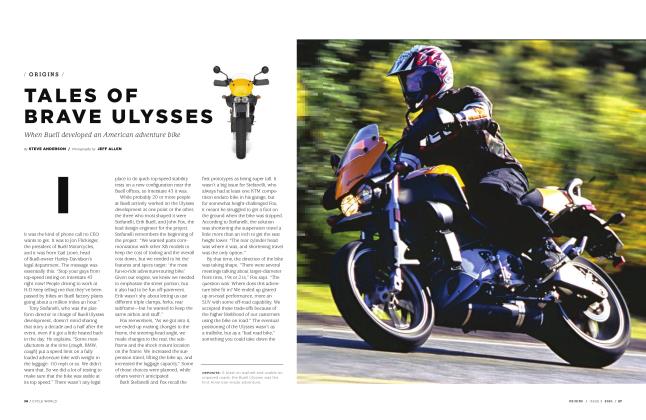

ORIGINS

ORIGINSTALES OF BRAVE ULYSSES

Issue 3 2021 By STEVE ANDERSON -

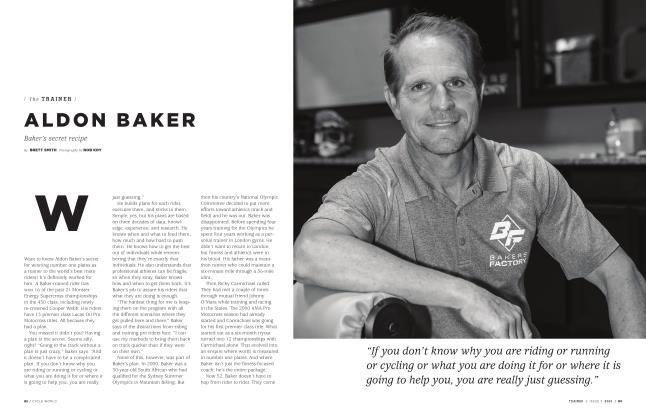

The TRAINER

The TRAINERALDON BAKER

Issue 3 2021 By BRETT SMITH -

CALIFORNIA TT

Issue 3 2021 By MICHAEL GILBERT -

TDC

TDCIN THE STYLE OF THE TIME

Issue 3 2021 By KEVIN CAMERON -

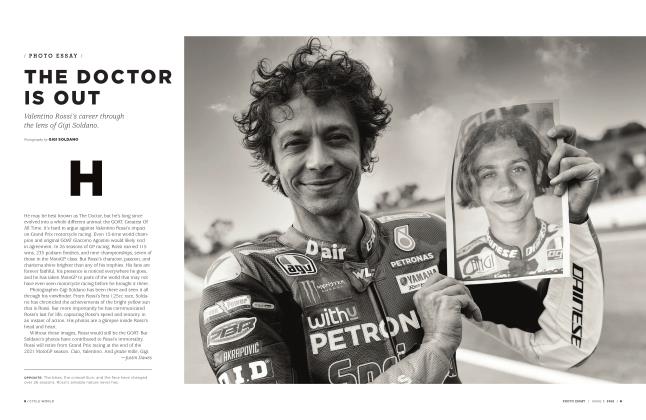

PHOTO ESSAY

PHOTO ESSAYTHE DOCTOR IS OUT

Issue 3 2021 By Justin Dawes -

UP FRONT

UP FRONTSERIES D

Issue 3 2021 By MARK HOYER