SURFACE COMPRESSION

TDC

Keeping metal from getting tired

KEVIN CAMERON

Back in the 1920s, helical steel valve springs were failing so often that some designers tried to solve the problem by providing up to 16 valves per spring, reasoning that they couldn’t all break.

The problem remained in the 1950s, despite the use of cleaner electric-furnace steels. Then some happy accidents showed a way forward: Some spring-makers were using tumbling as a way to deburr and clean freshly made springs, and it was noticed that such tumbled springs lasted longer than normal on test. Thoughtful engineers realized what was happening. Tumbling was subjecting spring wire surfaces to many impacts that left the surface layer in compression. Since cracks propagate mainly when tension pulls them apart, such precompression improved fatigue life by reducing tension in the wire’s surface at any given level of deflection.

The previous crack-prevention method had been to give highly stressed parts smoothly organic surfaces, as free of discontinuities as possible, and then to highly polish their surfaces to eliminate any and all surface defects that stress could transform into cracks. Service manuals for propeller blades and the lightweight crankcases of radial piston engines contain pages of photographs of typical surface scratches and dings, with instructions on which defects require the part to be scrapped and which may be polished out.

Yet the tumbled valve springs, covered with dings from surface impacts, lasted longer than untumbled springs. How could this be better applied? During World War II a more controlled way to placing surfaces in compression was developed, called “cyclopelting.” Tiny hard steel balls were fed into a fast-spinning rotor with radial vanes on it, emerging as a jet of tiny fast-moving “hammers” that could pound metal surfaces into compression. Over time, this was shown to be superior to the polishing previously used, as a means of extending the fatigue life of parts. Cyclo-pelting was replaced by a simpler way of accelerating steel balls: feeding them into a fastmoving jet of air.

Art Sparks and Tim Witham in the US decided to apply this to valve springs, combining it with then-new vacuum-remelted steel to make wire. By remelting the steel in vacuum, many impurities within the metal, which otherwise would have become crack nucleation sites, were boiled away. Their S&W valve springs quickly became known for exceptional fatigue resistance and were widely adopted for the most demanding applications.

When, in the final years of Yamaha’s famed TZ750 production roadracer, we had constant cracking of two of its crank flywheels, we were able to stop that cracking by bead blasting the region in which the cracks were starting. We never had another failure.

Fasteners with machine-cut threads broke constantly...

The concept of placing the surface of an object in compression as a means of strengthening it is also applied in tempered glass. Glass is potentially extremely strong in tension, but is vulnerable to cracks spread by tension stress acting on almost invisible surface scratches. “Tempering” the glass by suitable heat treatment places its surfaces in compression, removing most of this vulnerability. The interior of the glass is thereby placed in tension, but handles such stress easily because it has no free surface that can be scratched.

Experience with machine parts tells us that applied stress produces cracks most prolifically where there are discontinuities such as oil holes drilled into crankshafts, or where the cylindrical shape of bearing journals blends into the flat crank cheeks. This occurs because discontinuities concentrate stress on small areas. When BSA was testing prototypes of its postwar parallel twin, test riders returned every day with broken cranks in their engines. An automotive expert was called in and showed them the cause of the failures: concentration of stress at the small fillet radius where the conrod journals joined the rest of the crank. Crank vibration was rapidly accumulating fatigue cycles that were starting cracks in the fillets. The consultant used an electrically driven vertical shake table to excite vibration in a sample crank clamped to it, breaking it in two after just six minutes of resonant vibration.

The first part of the solution was to make the fillet radius larger and improve its surface finish, thereby reducing the severity of the stress concentration and removing surface defects from which cracks might originate. The second part has been to place the material in that fillet in permanent compression, not by shot-peening, which is hard to accurately direct onto such a small area, but by high-pressure rolling.

Crankshaft fillets are rolled by pressing the smoothly rounded edges of very hard steel rollers against them while rotating the crank. In the material being rolled, compression stress is several hundred thousand psi. In an application described in a paper from Oldsmobile, all journal fillets on a V-8 crank were rolled at the same time, at a speed of one rotation per second, adding just 47 seconds to the time required to produce each crankshaft. Even in the case of lower-strength materials such as nodular cast iron, fatigue life was doubled by deep-rolling. Today, process providers such as Hegenscheidt and SPMS report increases of fatigue strength as high as 400 percent.

I have written before of the constant failures of the cylinder hold-down bolts, or studs, of large piston aircraft engines. Fasteners with machine-cut threads broke constantly, and even when extremely smooth and carefully radiused threads were produced by precision grinding, failure rates remained unacceptable. Only when the threads were produced by cold forging, rolling rather than cutting the material into desired shape, did fastener reliability become satisfactory. Recently, Suzuki announced that one of the changes it has made to the third-generation Hayabusa engine is roll-forming of the internal threads in its aluminum crankcase. Both of these rolling processes place the surfaces of the threads they form in compression.

The use of intentional surface compression of materials to prevent cracking is just one among countless industrial concepts that are essential to making reliable the basis of our society in manufactured goods.

View Full Issue

View Full Issue

More From This Issue

-

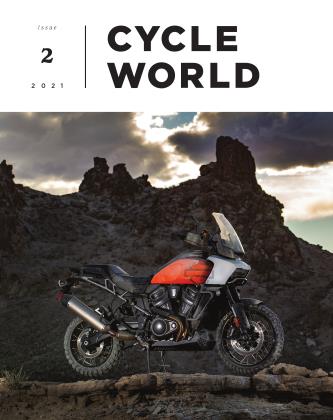

GAME CHANGER

Issue 2 2021 By JUSTIN DAWES -

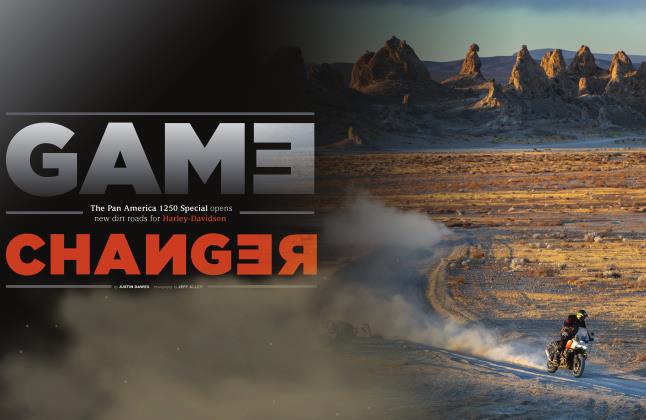

SUPER BIKE PIONEER

Issue 2 2021 By LINDSAY BROOKE -

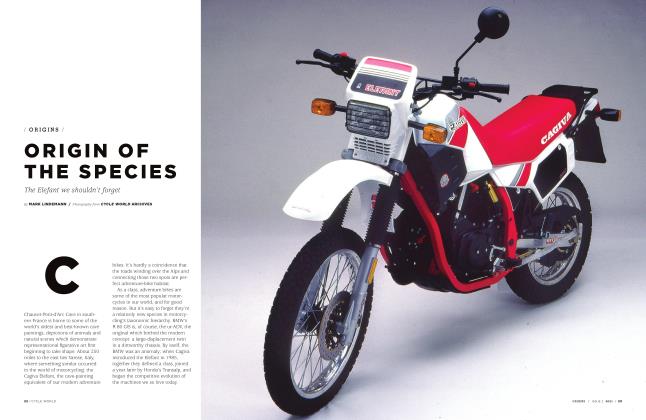

ORIGINS

ORIGINSORIGIN OF THE SPECIES

Issue 2 2021 By MARK LINDEMANN -

ELEMENTS

ELEMENTSMOTORCYCLE WHEELBASE

Issue 2 2021 By KEVIN CAMERON -

MAKING ICONS

Issue 2 2021 By MORGAN GALES -

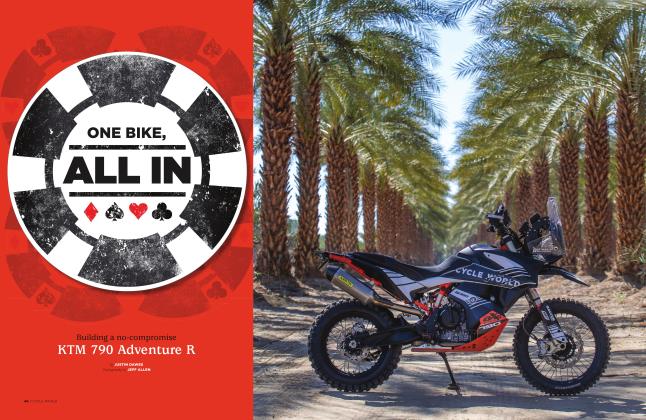

ONE BIKE, ALL IN

Issue 2 2021 By JUSTIN DAWES