UNDER PRESSURE

FUNDAMENTALS

What Pistons Have Become

KEVIN CAMERON

It is a visceral pleasure to examine a piston from a modern high-performance motorcycle engine such as Ducati’s V4 R. This is because it is the flow of stress that defines shape, just as the smooth flow of air gives grace to an engine’s intake ports.

Once the task of cylinder-filling is fully optimized, the key to more engine power is ever-higher rpm. From the earliest days of motoring, the need to abruptly accelerate and decelerate pistons as they alternately pump air and produce power has placed the greatest stress where the piston attaches to the connecting rod: around its wrist-pin bosses.

Cracks form and propagate in highly stressed metal in a process called fatigue failure. No real metal can be made 100-percent free of internal defects, and the presence of defects concentrates stress as it passes around them. Aluminum, still our best combination of hot strength and self-cooling heat conductivity, is a material that “remembers” all insults. This means that each cycle of applied stress—more than 530 piston reversals per second at 16,000 rpm—does sub-microscopic damage to the atomic bonds in a piston. The rate at which this damage accumulates is accelerated by temperature: Cracks move faster in hotter material.

At the same time, bearing loads and friction between pistons and the cylinder bores, against which connecting rod angularity forces them to decrease as parts are made lighter. This absolutely dictates that pistons in extreme engines can be little more than a thin disc to carry the piston rings, stabilized by minimal thrust skirts, carrying a braced box structure beneath to smoothly gather combustion and inertia forces and feed them into the short wristpin— small wonder that wristpins and the tail-hooks of carrier aircraft are made of similar materials.

Yet a piston this light, this minimal, offers too little in the way of a heat path from the hottest part—dome center—outward to the water-cooled cylinder wall. This is the reason for today’s use of piston-cooling oil jets. Located down in the crankcase, these jets shoot oil up against the underside of the piston crown close to one skirt. That oil splashes across under the dome surface, hits the interior of the opposite skirt, then falls back into the crankcase with its collected piston heat, there to be picked up by the oil system. In that process it is cooled and filtered before recirculation. This makes it practicable to make pistons as light as they have now become.

“Top piston rings run hot, hot enough perhaps to pick up soft aluminum from their grooves. ”

Look at the smooth, almost featureless crown of this piston— the side that faces combustion. Its smoothness allows vigorous fuel-air charge motion to continue as the piston rises on compression. That rapid motion—generated as intake velocity—stirs the charge and, once ignition has created a flame kernel at the spark plug, shreds and quickly distributes that flame so that combustion is fast, leaving minimum time for heat loss to surrounding metal surfaces.

The crown and piston-ring belt are anodized to increase their hardness. Top piston rings run hot, hot enough perhaps to pick up soft aluminum from their grooves. Anodizing prevents this.

At the front and rear of the crown are lozenge-shaped flat areas of “squish”—the parts of the piston that closest approach the head at top center. Any mixture trapped between them and the head is “squished” out rapidly, refreshing charge motion by forming fast-moving jets.

Turn the piston over and admire the smooth transitions between the ring belt, the nearly flat piston crown, and the box structure of this nine-cavity forging. Engineers use dynamic FEA—finite element stress analysis— to locate areas of maximum stress.

On computer screens, red zones of false color identify this stress. As shapes are made smoother, stress levels fall. Yet computers are not reality, which is why this world still requires the harshness of 100-hour full-throttle tests. This is validation—checking to be sure the computer model is speaking the truth.

Forging means that a slug of aluminum heated to a specified temperature is placed in a closed die forging press and squeezed into shape by tremendous pressure. This pressure not only closes defects in the metal but aligns its grain structure with its shape. Both increase fatigue strength—an essential quality at high rpm. The forged part is then machined to desired dimensions to fit the cylinder bore, define the compression ratio above its smooth dome, and accept the satisfying close fit of the wristpin and its retaining clips.

Pistons for production bikes have three rings—a top ring as close as possible to the crown to minimize emissions-generating ring crevice volume, a secondary sealing/heat-transfer ring, and below that, a modern three-piece oil scraper ring to keep oil where it belongs. For racing, the normal fit is just two—the gas seal ring and the oil ring.

This is a truly beautiful object.

View Full Issue

View Full Issue

More From This Issue

-

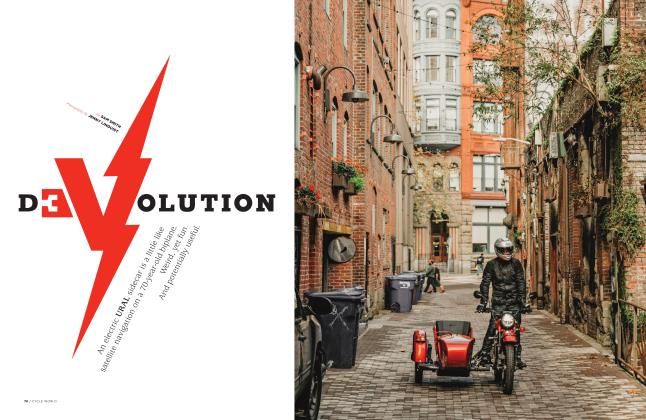

Devolution

Issue 2 2019 By Sam Smith -

Feature

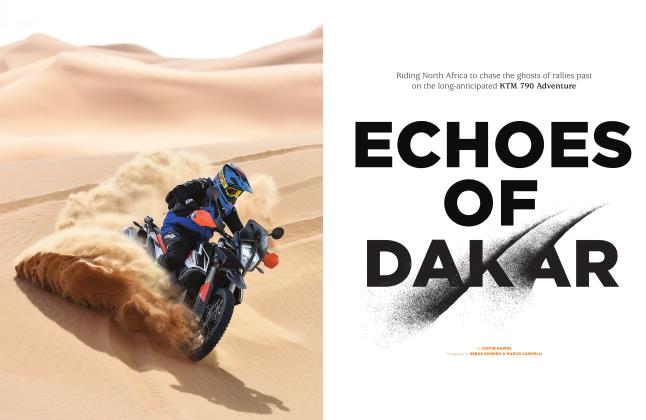

FeatureEchoes of Dakar

Issue 2 2019 By Justin Dawes -

TDC

TDCWhen the Engine Starts

Issue 2 2019 By Kevin Cameron -

Reviews

ReviewsBalance of Power

Issue 2 2019 By Michael Gilbert -

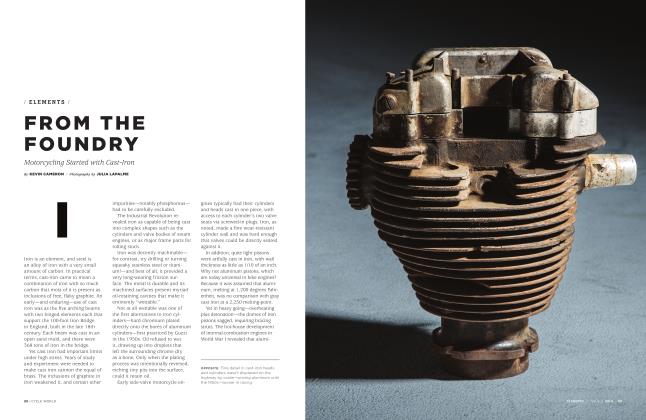

Elements

ElementsFrom the Foundry

Issue 2 2019 By Kevin Cameron -

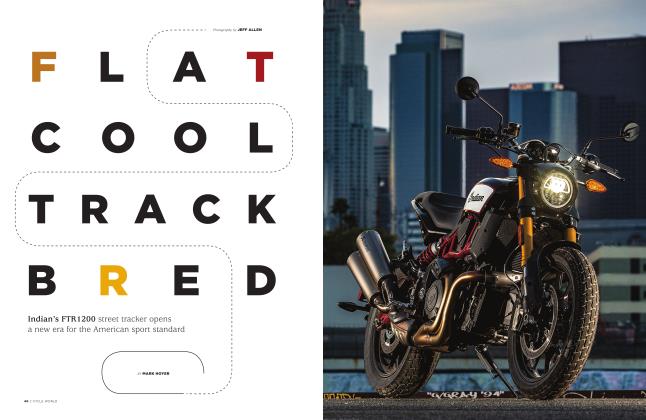

Reviews

ReviewsFlat Cool Track Bred

Issue 2 2019 By Mark Hoyer