SOMETHING FOR NOTHING?

IGNITION

NEWS

Audi makes fuel from water in this lab. But is it “green”?

Kevin Cameron

Audi has announced a process by which hydrocarbon liquids can be made from water and carbon dioxide.

Some readers have responded to this news by saying, “I knew it! I just knew one day they’d find a way to run cars on water!"

But then even the most credulous among us feels that tickle of skepticism. Wait a minute. Aren’t carbon dioxide and water the products of hydrocarbon combustion? The carbon combines (burns) with oxygen from the airto make carbon dioxide, and the hydrogen combines with oxygen to make water.

The historical fact is that schemes to synthesize hydrocarbon liquids from sources of carbon and hydrogen have existed foryears. Friedrich Bergius, beginning in 1913, developed methods of hydrogenating carbon by exposing powdered coal to very hot steam, at high pressure, and in the presence of a catalyst.

This is not something for nothing; it is putting in heat energy to create chemical structures, which, when they are later burned, will give up that same energy. Hydrocarbons burn to carbon dioxide and water, releasing heat energy, so we can start with those products, add energy, and “un-burn" them back into hydrocarbons. Energy is conserved.

Chemists Franz Fischer and FlansTropsch after1925 went at the problem differently, beginning not with coal but with carbon mon oxide, exposing it to hydrogen in high-pressure reactors at some 930 degrees Fahrenheit, where a catalyst helped move the reaction in the desired direction. Carbon monoxide was then plentiful in coal gas, made by pyrolyzing coal, driving off a mixture of hydrogen, methane, and carbon monoxide.

Hitler’s war planners in the late 1930s ordered large-scale construction of Fischer-Tropsch reactors to help make up for Germany’s lack of petroleum.

Students of history will know that it was this lack that sent Germany’s Army Group South toward the Baku oil fields (in what is today Chechnya), allowing the Soviets to prevail at Stalingrad (today Volgograd)the turning point of World War II in the east. Hitler had said, on June 1,1942: “If I do not get the oil of [Baku], then I must terminate this war.” In the end, scarcity of steel and Allied bombing kept the number of Germany’s fuel synthesis reactors small.

After the war, interest in synthetic fuel waned with the availability of plentiful Texas natural gas, delivered nationwide by pipeline.

More recently South Africa, during the years ofthat nation’s isolation over its racial policies, relied upon its “Sasol” synthetic fuel plants to convert plentiful coal into liquid fuels.

The OPEC oil embargo of 1973-74, driving oil prices up, restarted worldwide interest in synthetic fuel processes, but oil’s subsequent price seesaw has made investors cautious. Who wants to be stuck paying the note on a billion euros’ worth of single-purpose synthesis reactors if their product is price competitive only half the time?

Now comes Audi's announcement. Its process begins with carbon dioxide extracted from the air and with hydrogen electrolyzed from water by use of solaror wind-generated electricity. Carbon dioxide is adsorbed from the air onto a sorbent with a special affinity. Then the sorbent alone is airlessly heated to 200 degrees Fahrenheit to release pure carbon dioxide. This is reacted with hydrogen in a stepped process at 430 degrees Fahrenheit and 370 psi, producing first a synthesis gas then hydrocarbon liquids at a claimed cost of one euro per liter (just less than $5 per gallon). The efficiency of the process is the ratio of the energy required to produce the liquids to the chemical energy of the liquid product. This, it is claimed, is 70 percent.

Because this process produces no aromatic components (carbon ring compounds, which are difficult for diesels to ignite) and contains zero sulfur contamination, its product is especially suited to diesel engines. It would be added to fossil-derived diesel fuels to boost their ignitability.

A natural competitor is the GTL, or Gas-To-Liquids, conversion now being used to process oil field natural gas into a similarly ideal diesel fuel. Natural gas can be liquefied only at very low temperature and high pressure, making international transport by ship technically difficult. Much better, therefore, to convert the natural gas into a “room-temperature” liquid fuel such as diesel or gasoline, which can be handled by any tanker ship.

The keys to success for Audi’s process are: (1) a continuing high oil price, (2) availability of low-cost solaror wind-generated electricity, and (3) investors willing to accept the proven risks.

Even with all this, it’s not something for nothing.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

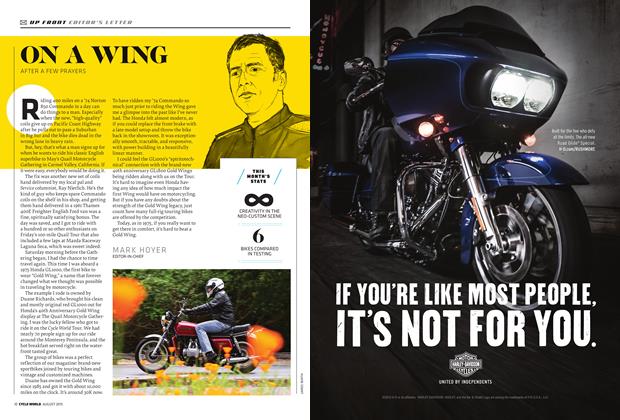

Up FrontOn A Wing

August 2015 By Mark Hoyer -

Intake

IntakeIntake

August 2015 -

Ignition

IgnitionRacer Ride

August 2015 By Blake Conner -

Cw 25 Years Ago August 1990

August 2015 By Don Canet -

Ignition

IgnitionTop Priority: Street Riding Use Your Imagination

August 2015 By Nick Ienatsch -

Ignition

IgnitionMoto What?

August 2015 By Peter Jones