FAILURE

IGNITION

TDC

AS USUAL, WE CAN BLAME IT ON ENTRAINED ALUMINUM OXIDE

KEVIN CAMERON

Air-cooled cylinders (most especially two-stroke cylinders) and cylinder heads, plus all kinds of pistons, are especially liable to cracking because they run hot and are wracked by thermal as well as mechanical stress.

At Talladega in 1971, my rider Cliff Carr put our H1R Kawasaki on the front row. As I rolled the bike onto the grid, Steve Whitelock, Yvon DuHamel’s mechanic, said, “What’re you doing here?” For once, I had the presence of mind to say the right thing. “We belong here.”

The physics of materials said otherwise in the race—a head cracked, allowing its copper gasket ring to blow. Here’s how. As the engine runs, the center of the head is heated to high temperature by its exposure to combustion, but the outer parts of the head—its array of cooling fins—run much cooler because of the fresh air streaming over them. The center of the head expands a lot, but its outer parts, being cooler, expand less. Who wins? The hot center expands with such force that it slightly and permanently stretches the outer parts of the casting. When the engine is stopped and cools off, now the permanently expanded outer part can no longer allow the combustion chamber to quite return to its original dimension, thereby putting the center of the head in tension. Accumulated cycles of heat stretching and cooling into tension produce stress that will find and expand defects in the casting. Parts have lifetimes.

Today, advanced casting practice calls for non-turbulent mold filling from the bottom of the mold. This allows the film of aluminum oxide that always floats on molten aluminum to rise smoothly to the top of the mold rather than being entrained by a turbulent top fill. If entrained, bits of aluminum oxide become part of the casting, constituting numerous planes of weakness. It was customary to blame the crack propensity of aluminum castings on “porosity,” but entrained aluminum oxide is the likelier culprit.

For many years, it was standard practice to manufacture crankpins for pressed-together two-stroke crankshafts with a central bearing race of larger diameter than the ends of the pin, which pressed into crank flywheels. Where the smaller press-fit diameter became the larger diameter of the central bearing race, there was a step. Stress is concentrated at such steps—or at any sudden change of cross-section. The only crankpin breakages I have ever seen were of this type, and the crack that began the failure originated in this step. To make such cracking less likely, the original drawing surely showed the step as a smooth radius rather than a step with a sharp angle, but tools grow dull after a certain number of parts. Any imperfection in that “fillet radius” has the potential to become a crack.

It wasn’t long before all manufacturers abandoned such stepped crankpins in favor of smooth, single-diameter pins.

Four-stroke engines with one-piece cranks also have fillets where their crankpins and main journals join the crank cheeks. The larger the radius of these fillets, the more resistant they are to cracking, and, just as with stepped crankpins, failures usually originate in the fillets. Several makers of motorcycle engines have had to take a deep breath, make the crankshaft fillet radii bigger, and narrow the bearing shells enough to make room, after having a rash of fillet cracking in a new model. It is also common to either roll or shot-peen fillets to place their material in compression. Any applied stress must first overcome this initial compression before any tension can be produced in the fillet. It is tensile stress that nourishes cracking.

In 2009,1 saw Kenny Roberts across a hotel lobby in Indianapolis. I walked over and handed him a blue-anodized aluminum bolt. Without an instant’s hesitation, he said, “One of those goddamned things cost me the win at Daytona in 1974.”

BY THE NUMBERS

3 DAYTONA 200 WINS FOR KENNY ROBERTS (WOULD HAVE BEEN FOUR, IF NOT FOR A FAILED HEAD BOLT IN 1974)

3,600 PRICE OF A YAMAHA TZ750A, IN DOLLARS, IN 1974

26 RACE NUMBER OF CLIFF CARR’S KEVIN CAMERONBUILT KAWASAKI H1R IN 1972

Sixteen such bolts, plus six stainless cap screws, retained the two cylinder heads on the Yamaha TZ750A engine. Occasionally— pop—the head of a bolt would break off. Kenny’s bike began to lose cooling water after such a failure, forcing him to accept second to Giacomo Agostini in the Daytona 200.

Was the problem too small a fillet radius where the bolt’s shank joined the head? Notchy machining marks in that fillet? Did the edge of the copper washer under each bolt nick the softer fillet? Improper heat treatment? Yamaha sent out clear-anodized replacements that never broke, but there’s no warranty on finishing second in the 200.

One maker had a problem with carbon accumulation in combus-

tion chambers, and in some bikes a chunk of that carbon could stick to an exhaust valve or seat, preventing that valve from closing properly. When a valve is “unseated” in this or in any other way (such as seat warpage or development of “negative valve clearance”) it is robbed of its best source of cooling: full contact with the seat. Some heat does get conducted down the stem and into the valve guide, but the best cooling, by the shortest heat path, is into the valve seat via good contact. It doesn’t take long for a valve in this circumstance to get really hot and for the flow of combustion gas to blowtorch a big section out of the valve. This kind of thing is rare today, kept that way by accurate mixture control, good cooling, and mature valve materials.

The legendary Yamaha TZ750 had a jackshaft that carried power from the middle of its twin, endto-end crankshafts over to the dry clutch on the right. The water pump and gearbox oil pump were driven by cross-axis gears from this shaft. The ignition rotor shaft was also driven from it but by large spur gears. Cross-axis gears operate with considerable sliding, since they are halfway to being worm gears. This made them vulnerable to wearing out unless actual gear oil (containing extreme pressure additive) was used in the transmission, rather than ordinary engine oil. The spiral teeth on the jackshaft simply wore away until there was no longer enough tooth height to drive the water pump, at which point the temp gauge spiked and the engine pushed out all its water. Replacing the jackshaft required splitting the engine, and few racers carried a replacement.

KENNY'S BIKE BEGAN TO LOSE COOLING WATER AFTER SUCHA FAILURE, FORCING HIM TO ACCEPT SECOND TO GIACOMO AGOSTINI IN THE DAYTONA 200.

Adequate testing forces nature to show her hand before we play ours.

View Full Issue

View Full Issue

More From This Issue

-

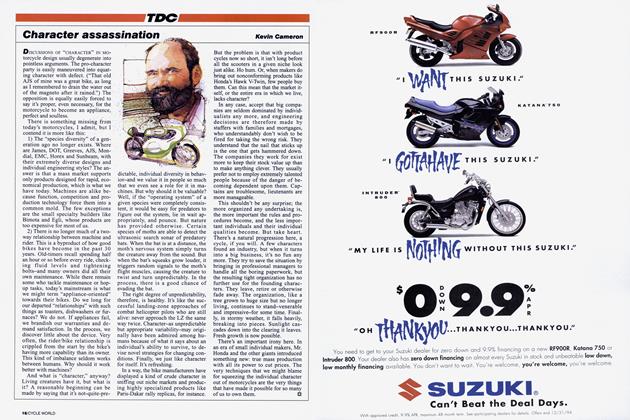

Up Front

Up FrontMoto Film Fest

December 2015 By Mark Hoyer -

Intake

IntakeIntake

December 2015 -

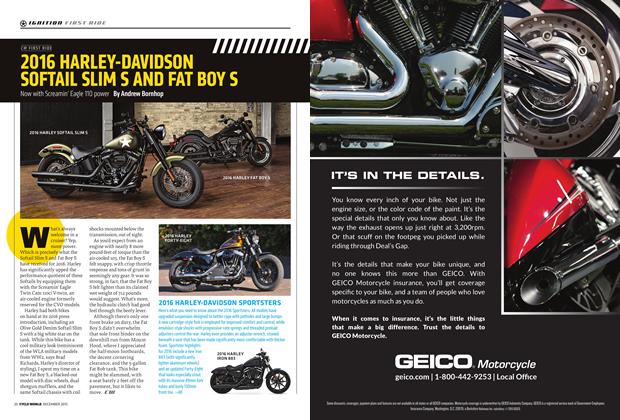

Ignition

Ignition2016 Harley-Davidson Softail Slim S And Fat Boy S

December 2015 By Andrew Bornhop -

Ignition

IgnitionCw 25 Years Ago December 1990

December 2015 By Don Canet -

Ignition

IgnitionChoose the Best Teachers Search For Great Sources

December 2015 By Nick Ienatsch -

Ignition

IgnitionHere Is Here, There Is There

December 2015 By Peter Jones