Casting Chronicles

TDC

KEVIN CAMERON

OVER THE PAST FEW YEARS, WE HAVE heard that one manufacturer after another has adopted new die-casting processes. One year at Daytona, Miguel Duhamel’s long-time Honda crew chief, A1 Ludington, was heard complaining that the Yamaha-Hitachi casting system was making trouble for his rider. How so? The new Yamaha 600s weighed 30 pounds less because of it. This year, it is the Ritter-Vacural process in the news, as Ducati has finally applied this technology to its standout problem of many years: crankcase cracking in severe service, such as racing.

Why not forge the crankcases, as was done for large aircraft radial piston engines? Forging not only presses voids out of existence, it also aligns metal crystals to produce directional strength. Ducati engineers would have loved forged cases, but the per-horsepower cost of those radial engines was twice that of cast-block engines. Motorcycles are a market product, so excellence put out of reach by price is pointless.

Older books on the subject generally refer to the notorious weakness of cast metal in vague terms of “porosity.” Experience shows that any deviation from continuous, uniform metal in a part can act as a nucléation site for cracking. This includes voids, surface scratches and inclusions (bits of foreign matter in the metal).

In a way, this parallels what was learned about glass—another material notoriously lacking in strength. In former times, every student of chemistry had some familiarity with glassblowing. Heat the center of a glass rod in a Bunsen flame, then pull the ends apart and you could make glass fibers. When such fibers were tested, they were found to be incredibly strong, stronger than the best alloy steels. Then why were windows and glassware so fragile? The eventual answer was “because their surfaces are a maze of fine scratches.” When an inaccurately thrown ball applied stress to a window pane, the glass broke because every scratch is a crack-in-waiting. Apply sufficient stress, and cracks race through the material. Glass fibers were too small to bear scratches of the necessary size, and from them developed our present industries producing fiber-reinforced composite materials.

Foundries casting aluminum learned ways to reduce porosity from water vapor and mold gases. Watch old-time movies of such work and you will see a shovelful of mysterious substance tossed into the melt. The goal at the time was simply better castings, not seeking understanding. For a very long time, foundry work remained a craft unsullied by science. Engineers or the drafting office could propose a shape, but the foundrymen had the last word on what could be successfully poured. Casting is versatile; by the use of cores and other mold parts hollow or otherwise, complex shapes can be produced that would be impossible to forge or machine. Think of a cylinder head with its internal coolant passages, ports and valve-spring cavities.

Sixty years ago, some designers were attempting to seat valves directly on the aluminum head material. Part of their motivation was that the room needed for inclusion of a separate hard valveseat ring reduced the maximum valve size, and part was a desire to improve valve cooling. It was noticed that the aluminum forming the exhaust-valve seat became spongy in use. In some cases, this could be “fixed” by carefully peening (that is, locally forging) the material to compact it, then re-cutting the seat. Twenty-five years later, Cosworth was having similar trouble with sponginess around the exhaust valves of its new turbocharged DFX racing engine, even with separate hard valve-seat rings.

Help was at hand. John Campbell at the University of Birmingham had developed a novel casting process based upon some important ideas. Campbell knew that a skin of aluminum oxide instantly forms on molten aluminum that is exposed to air. Unlike the “skins” that form on pudding or gravy, this thin layer of aluminum oxide was not soluble in the melt. If turbulent conditions occurred during casting, oxide skin formed, was torn to pieces by the motion of the metal, reformed and was entrained in the melt.

Careful investigation revealed that aluminum oxide in cast metal was present in the form of what Campbell calls “bifilms.” The side of the skin originally facing the melt could bond to it, but the outer surface, contaminated by adsorbed gas, could not. When entrained in the melt, therefore, the sheets of oxide tended to fold over with the contaminated surfaces facing each other. This was a “bifilm.” When the casting cooled, the unbonded inner-facing surfaces were so intimately pressed together that their presence was all but undetectable. Yet when stress was applied, the discontinuity of their facing but unbonded surfaces was ready to propagate as a crack.

When such bifilms were present in aluminum material near a valve seat, hot combustion gas could enter between films to erode the material, eventually rendering it spongy and weak.

If the pouring of aluminum produced turbulence that entrained these aluminum oxide bifilms, how might such entrainment be avoided? One system that has been used is to perform the casting process in an inert atmosphere of argon gas. Another is to evacuate the air from molds, but oxide films form anyway at affordable levels of pumping.

Campbell decided to fill molds from below, carefully holding the inflow velocity to a value that could not create “fountains” that would entrain oxide films. At a low enough velocity, oxide skin would form on the rising surface of hot metal, continually tearing in the middle and reforming. The strength of the torn film would pull it to the walls of the mold, with none being entrained in the bulk metal. Special care had to be taken to avoid forming waterfalls as lower parts of the mold filled by metal spilling over from above.

When Cosworth tested castings made in this way, their physical properties were found to be markedly better than anything previous. Not only was the DFX’s problem with sponginess ameliorated, but it was possible to reduce wall thicknesses in many places in engine castings with no loss of strength. The result was lighter parts.

Cosworth adopted Campbell’s process, and Campbell has gone on to pioneer other new casting processes. Read more about it in Campbell’s book, called, appropriately enough, Castings.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontThe Throaty Ghost

FEBRUARY 2012 By Mark Hoyer -

Roundup

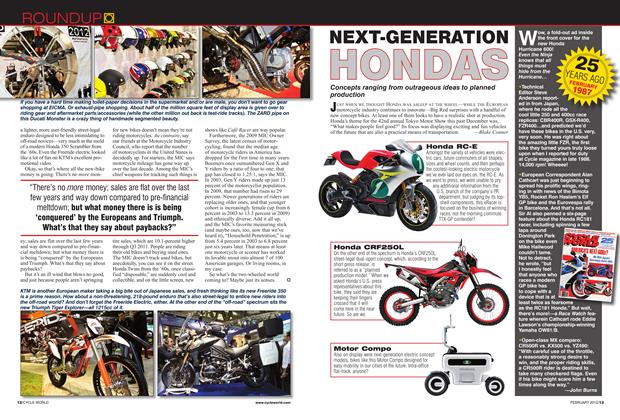

RoundupWhat's the Two-Wheel World Coming To Anyway?

FEBRUARY 2012 By John Burns -

25 Years Ago February 1987

FEBRUARY 2012 By John Burns -

Roundup

Roundup2012 Zeros

FEBRUARY 2012 By Steve Anderson -

Roundup

RoundupDaineses D-Air Street

FEBRUARY 2012 By John Burns -

Roundup

RoundupMilestones Along the Way

FEBRUARY 2012 By Paul Dean