TDC

About the Cyclone

KEVIN CAMERON

WHEN I FIRST LEARNED ABOUT THE existence of the 1915 Cyclone, it seemed to materialize out of nothing-a high-revving, overhead-cam visitor from the future, plopped down into a pre-WWI world of low-performance flathead or suction-over-exhaust motorcycles.

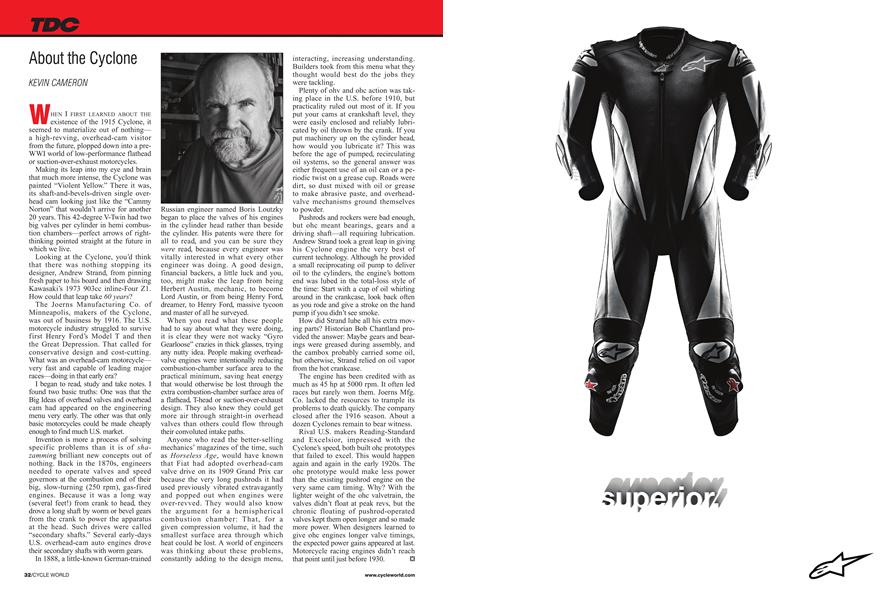

Making its leap into my eye and brain that much more intense, the Cyclone was painted “Violent Yellow.” There it was, its shaft-and-bevels-driven single overhead cam looking just like the “Cammy Norton” that wouldn’t arrive for another 20 years. This 42-degree V-Twin had two big valves per cylinder in hemi combustion chambers—perfect arrows of rightthinking pointed straight at the future in which we live.

Looking at the Cyclone, you’d think that there was nothing stopping its designer, Andrew Strand, from pinning fresh paper to his board and then drawing Kawasaki’s 1973 903cc inline-Four Zl. How could that leap take 60 years1?

The Joerns Manufacturing Co. of Minneapolis, makers of the Cyclone, was out of business by 1916. The U.S. motorcycle industry struggled to survive first Henry Ford’s Model T and then the Great Depression. That called for conservative design and cost-cutting. What was an overhead-cam motorcycle— very fast and capable of leading major races—doing in that early era?

I began to read, study and take notes. I found two basic truths: One was that the Big Ideas of overhead valves and overhead cam had appeared on the engineering menu very early. The other was that only basic motorcycles could be made cheaply enough to find much U.S. market.

Invention is more a process of solving specific problems than it is of shazamming brilliant new concepts out of nothing. Back in the 1870s, engineers needed to operate valves and speed governors at the combustion end of their big, slow-turning (250 rpm), gas-fired engines. Because it was a long way (several feet!) from crank to head, they drove a long shaft by worm or bevel gears from the crank to power the apparatus at the head. Such drives were called “secondary shafts.” Several early-days U.S. overhead-cam auto engines drove their secondary shafts with worm gears.

In 1888, a little-known German-trained Russian engineer named Boris Loutzky began to place the valves of his engines in the cylinder head rather than beside the cylinder. His patents were there for all to read, and you can be sure they were read, because every engineer was vitally interested in what every other engineer was doing. A good design, financial backers, a little luck and you, too, might make the leap from being Herbert Austin, mechanic, to become Lord Austin, or from being Henry Ford, dreamer, to Henry Ford, massive tycoon and master of all he surveyed.

When you read what these people had to say about what they were doing, it is clear they were not wacky “Gyro Gearloose” crazies in thick glasses, trying any nutty idea. People making overheadvalve engines were intentionally reducing combustion-chamber surface area to the practical minimum, saving heat energy that would otherwise be lost through the extra combustion-chamber surface area of a flathead, T-head or suction-over-exhaust design. They also knew they could get more air through straight-in overhead valves than others could flow through their convoluted intake paths.

Anyone who read the better-selling mechanics’ magazines of the time, such as Horseless Age, would have known that Fiat had adopted overhead-cam valve drive on its 1909 Grand Prix car because the very long pushrods it had used previously vibrated extravagantly and popped out when engines were over-revved. They would also know the argument for a hemispherical combustion chamber: That, for a given compression volume, it had the smallest surface area through which heat could be lost. A world of engineers was thinking about these problems, constantly adding to the design menu, interacting, increasing understanding. Builders took from this menu what they thought would best do the jobs they were tackling.

Plenty of ohv and ohc action was taking place in the U.S. before 1910, but practicality ruled out most of it. If you put your cams at crankshaft level, they were easily enclosed and reliably lubricated by oil thrown by the crank. If you put machinery up on the cylinder head, how would you lubricate it? This was before the age of pumped, recirculating oil systems, so the general answer was either frequent use of an oil can or a periodic twist on a grease cup. Roads were dirt, so dust mixed with oil or grease to make abrasive paste, and overheadvalve mechanisms ground themselves to powder.

Pushrods and rockers were bad enough, but ohc meant bearings, gears and a driving shaft—all requiring lubrication. Andrew Strand took a great leap in giving his Cyclone engine the very best of current technology. Although he provided a small reciprocating oil pump to deliver oil to the cylinders, the engine’s bottom end was lubed in the total-loss style of the time: Start with a cup of oil whirling around in the crankcase, look back often as you rode and give a stroke on the hand pump if you didn’t see smoke.

How did Strand lube all his extra moving parts? Historian Bob Chantland provided the answer: Maybe gears and bearings were greased during assembly, and the cambox probably carried some oil, but otherwise, Strand relied on oil vapor from the hot crankcase.

The engine has been credited with as much as 45 hp at 5000 rpm. It often led races but rarely won them. Joerns Mfg. Co. lacked the resources to trample its problems to death quickly. The company closed after the 1916 season. About a dozen Cyclones remain to bear witness.

Rival U.S. makers Reading-Standard and Excelsior, impressed with the Cyclone’s speed, both built ohc prototypes that failed to excel. This would happen again and again in the early 1920s. The ohc prototype would make less power than the existing pushrod engine on the very same cam timing. Why? With the lighter weight of the ohc valvetrain, the valves didn’t float at peak revs, but the chronic floating of pushrod-operated valves kept them open longer and so made more power. When designers learned to give ohc engines longer valve timings, the expected power gains appeared at last. Motorcycle racing engines didn’t reach that point until just before 1930.

View Full Issue

View Full Issue

More From This Issue

-

Columns

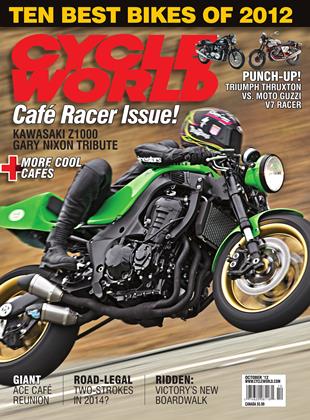

ColumnsUp Front

October 2012 By Mark Hoyer -

Roundup

RoundupTwo-Stroke Resurrection

October 2012 By Steve Anderson -

Round Up

Round Up25 Years Ago October 1987

October 2012 By Don Canet -

Round Up

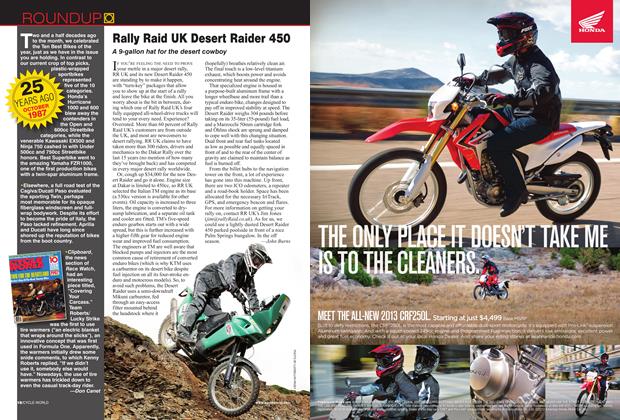

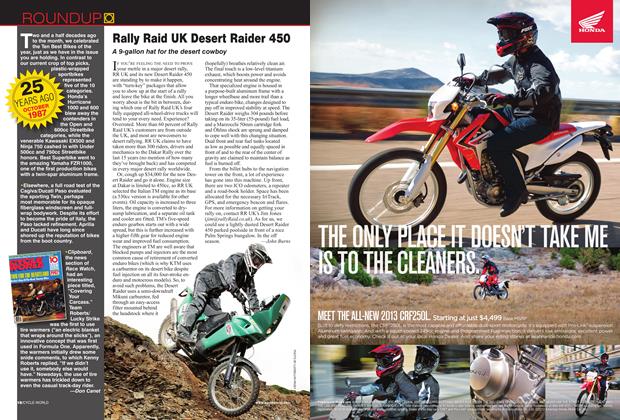

Round UpRally Raid Uk Desert Raider 450

October 2012 By John Burns -

Roundup

RoundupOn the Record: Paolo Ciabatti

October 2012 By Matthew Miles -

Roundup

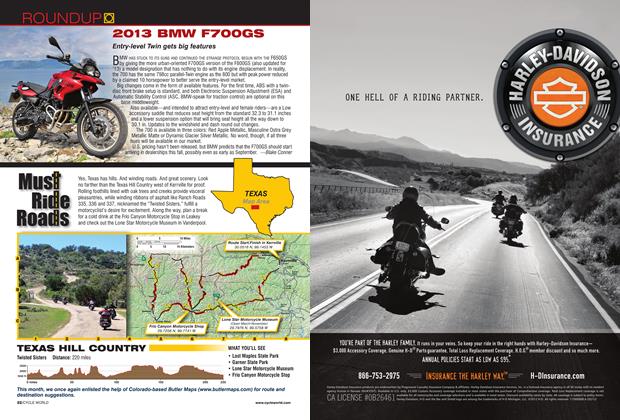

Roundup2013 Bmw F700gs

October 2012 By Blake Conner