SERVICE

PAUL DEAN

Bespoke spokes

Q When you buy a new bike, all its spokes have been properly torqued by the factory, the wheels are perfectly round and their balance is spot-on. So, why not place a drop or two of wicking Loctite #290 or AA on each spoke nipple, let the thing set overnight and never worry about spoke torque again? As a bonus, you get sealed rims that might be convertible (except for their profile) to tubeless.

For what it’s worth, AA was designed specifically to seal porosities in compressor tanks, etc. by wiping some on the suspect area, allowing it to set in the absence of other than surface oxygen, then wiping off any excess. Its sibling, #290, was designed specifically for threaded fasteners, but I think they are almost interchangeable. A Permatex version of #290 is available at auto parts stores. David Reid Chenault

Mount Sterling, Kentucky

A Interesting idea, but it would not be a remedy for the loosening of spokes on a new wheel or even on a relaced one. Spokes don’t loosen due to the nipples turning; they do so because the nipples gradually seat in the rim, the hooked ends of the spokes seat in the hub, the rim flexes during use and, in some cases, the spokes even stretch ever so slightly.

Either combined or separately, those factors can allow spokes to loosen and the wheel to grow out-of-round.

But according to Robert Buchanan of Buchanan Spoke & Rim (www. buchananspokes.net), a family-owned wheel business that has been in operation for 54 years, spoke nipples do not unscrew. “You have an inflated inner tube pushing against the nipples through a rim strip,” says Buchanan. “That alone keeps the nipples from turning. And the way the nipples are countersunk into the rim provides additional friction surface that helps prevent them from unscrewing. Also, motorcycle spokes have a very fine thread pitch, between 32 and 40 threads per inch; so, even if a nipple would turn a few degrees, that would not cause a meaningful loosening of the affected spoke.” Buchanan says that the only time he has seen spoke nipples rotate has been on some very rare spoked automotive wheels that use coarse threads and tubeless tires.

Buchanan also strongly discourages the use of thread locker or sealer on spoke nipples. “We already often have trouble freeing up and turning nipples on some wheels because of accumulated rust or corrosion,” he says. “Putting thread locker on them would make that problem even worse.”

Rage against the machines

Q lf some new technology doesn’t make things that much better, the logical question is, why use it? For example, why the need for an expensive, needless thing such as a ride-by-wire throttle? I have replaced clutch and throttle cables on the side of the road and can’t imagine doing anything to repair a failed computer-controlled unit on a trip without investing huge amounts of money and time waiting for the exact part. Sometimes, a cable, a carb and getting to really know your bike is 10 times better than having the bike do it all for you. Jeff Gilbert

Burlington, Vermont

A To a certain extent, I agree: Technology for its own sake—which you see more often in modern cars than on bikes—can offer just as much grief and potential expense as convenience. But while ride-by-wire does complicate what once was a dead-simple system, it is far from “needless” technology.

For one thing, RBW has allowed many current bikes to meet stringent noise and emissions requirements despite having highly tuned engines that offer tremendous performance. Under certain conditions, the ECU determines the actual throttle opening, despite what the rider might do with the twistgrip. Sometimes, those circumstances involve the combination of engine rpm, road speed and transmission gear at which sound levels are officially tested; if the throttle were opened as much as the rider requested, the bike would fail the sound test. Same goes for certain aspects of exhaust emissions certification: To pass that test, throttle openings might have to be slightly less than what the rider dialed up. And if manufacturers are caught selling motorcycles that cannot meet those requirements, the penalties are severe.

Then there is the rideability factor. Modern sportbike engines, especially those in the liter class, pump out huge amounts of power throughout the entire rpm range. With a manual throttle, even a little too much twistgrip during a midcorner lean could cause a crash. But with ride-by-wire (and, when applicable, traction control, which also works via computer-controlled throttles), power can be modulated in a way that greatly lessens the likelihood of such an outcome, regardless of how far or how rapidly the twistgrip is opened.

Ride-by-wire even has proven valuable in racing. The TenKate Honda CBR1000RR of Jonathan Rea languished in World Superbike because if it were tuned to be competitive on the straights, its original-equipment manual throttle made the power too hard to manage in the corners. But once the FIM permitted the big CBRs to have ride-by-wire, the engine was retuned for more power; and now that the computer can modulate that power when necessary, Rea has been able to run up front. So, yes, without technology, the world would be a much simpler, potentially less-expensive place. But for motorcycle riders in particular, it might also be a more dangerous place, even though we all could be riding bikes that offered less-exciting performance.

Dynomad

Q In the August issue, you guys evaluated the Cobra FÍ2000 PowerPro, and Eve got some questions about it. I have a 2004 Kawasaki Nomad 1500.1 love the bike, but it could sound a little healthier and have a bit more power. It already has a K&N air filter, and I’ve just about talked myself into getting the Vance & Hines Classic Bagger exhaust, so I’ll also have to do something with the fuel injection. I’ve been leaning toward the FÍ2000 as opposed to a Power Commander because I’m pretty sure I can install the exhaust and FÍ2000 myself without needing a shop. The cost of the exhaust, fuel management, mapping and,

I was told, dyno tuning would be prohibitive, but if I can eliminate the last two steps, that could change things. What is the real benefit in dyno tuning? I’m not a racer; I wouldn’t be riding a Nomad if I was. I know you can’t give me real numbers without doing a comparison test, but, in your opinion, would changing the exhaust and installing the FÍ2000 give me more torque and better throttle response? When my wife and I take trips, the bike will be fully loaded, sometimes pulling a cargo trailer for camping. Steve Prescott Submitted via America Online

A As you have implied, I can’t be certain how much effect any of those modifications would have on your Nomad without actually installing them and then running the bike on a dyno or at least testriding it. But I can tell you that the FÍ2000 may very well provide the same increases in performance and throttle response as would a Power Commander.

Dynamometer tuning works in concert with any of the several fuel controllers on the market to let the dyno operator adjust an injection system’s fuel mapping for all the variables of engine rpm and throttle position that would occur in actual riding. The dyno can simulate those variables, allowing the operator to dial-in the ideal fuel mixture for each one of them.

You have a few options here. Cobra’s FÍ2000 is indeed a simple plug-and-play installation that automatically adjusts the mixture while the bike is being ridden. Dynojet also has a similar system called Auto Tune, although it works in conjunction with a Power Commander and includes an O2 sensor, all of which makes it a more-expensive package.

Once again, I can’t tell you which option would provide the best overall results on your Nomad. But given that you are not changing any of the engine’s major power-producing components (cams, heads, pistons, etc.), I believe that the performance differences between them would not be significant.

Got a mechanical or technical problem with your beloved ride? Can’t seem to find workable solutions in your area? Or are you eager to learn about a certain aspect of motorcycle design and technology? Maybe we can help.

If you think we can, either: 1) Mail a written inquiry, along with your full name, address and phone number, to Cycle World Service,

1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/631 -0651; 3) e-mail It to CW1Dean@aol.com; or 4) log onto www.cycleworld.com, click on the “Contact Us” button, select “CW Service” and enter your question. Don’t write a 10page essay, but if you’re looking for help in solving a problem, do include enough information to permit a reasonable diagnosis. And please understand that due to the enormous volume of inquiries we receive, we cannot guarantee a reply to every question.

View Full Issue

View Full Issue

More From This Issue

-

Columns

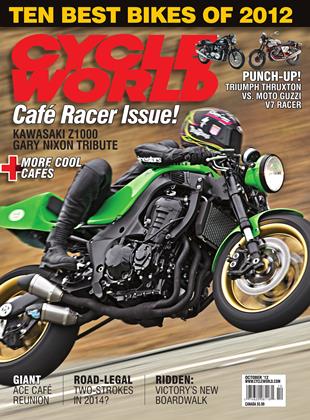

ColumnsUp Front

October 2012 By Mark Hoyer -

Roundup

RoundupTwo-Stroke Resurrection

October 2012 By Steve Anderson -

Round Up

Round Up25 Years Ago October 1987

October 2012 By Don Canet -

Round Up

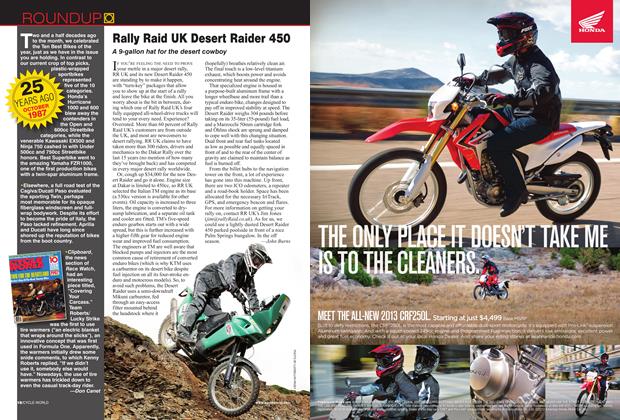

Round UpRally Raid Uk Desert Raider 450

October 2012 By John Burns -

Roundup

RoundupOn the Record: Paolo Ciabatti

October 2012 By Matthew Miles -

Roundup

Roundup2013 Bmw F700gs

October 2012 By Blake Conner