ToolTime

You can’t do much work on most motorcycles these days without encountering socket-head (Allen) and Torx bolts and screws. These types of fasteners tend to be less prone to damage during removal than are slotted and Phillips screws; and because their toolaccess surfaces are internal rather than external, they can fit into tighter spaces than hexhead fasteners that require clearance around the outside to allow room for a socket.

But cheap Allen and Torx tools are not a good solution; they often are a sloppy fit into the bolt or screw, and their material sometimes is barely harder than that of the fastener. Either condition can lead to the fastener getting rounded out, turning what might be a simple job into a drawnout, agonizing ordeal.

CruzTOOLS (www.cruztools.com) has tried to deal with this dilemma by producing three Allen and Torx Socket Bit Sets that are high in quality but reasonable in price. The 10-piece Inch Hex Bit Set (part #IN38HBS; $24.95) has bits ranging from 5/64to 3/sinch. Its metric equivalent, the 8-piece Met-

ric Hex Bit Set (part #ME38HBS; $22.95), goes from 2.5mm to 12mm. The 10-piece Torx Bit Set (part #TS38TBS; $29.95) runs from T10 to T55, including a T27, the most prevalent Torx size used on later-model Harley-Davidsons.

In all three sets, every socket uses a 3/sinch square drive, and each set comes on a steel socket rail with a plastic handle on one end. That makes them simple to store in a toolbox and easy to carry to the job. Plus, all the sockets’ sizes are marked with a large laser imprint, so they’re easy to read, even for codgers who can’t find their bifocals.

These socket bit sets are comparable in quality to most brand-name equivalents yet cost less, especially considering that you get more bits per set, along with a handy tool rail. And like other high-end tools, the CruzTOOLS sets carry a lifetime guarantee.

Okay, so technically, what you see here are not “tools”; but these LiteLoc Rim Locks from Motion Pro (www.motionpro.com) almost qualify anyway, since they promise to reduce the likelihood that you’ll have to use actual tools for removal of either of your dirtbike’s wheels to fix a flat caused by the abrasion of a rim lock against a tube.

Rather than being made of aluminum or steel and rubber, the LiteLocs are molded of a high-strength nylon composite material that’s exceptionally light and highly impact-resistant. The front Loc (part #11 -0058;

$17.50), for 1.40and 1.60-inch-wide rims, weighs just a little more than an ounce, while the rear (part #11 -0060; $18.99), for 2.15inch rims, weighs just 2.4 ounces. The con-

toured inner is designed to protect the tube from abrasion against the lock, and the five angled ribs on each side pinch the tire’s bead securely against the rim. The LiteLocs are held in place by a beautifully machined tall aluminum nut atop an equally finished beveled washer that’s radiused on the bottom to fit over the curved center section of the rim.

Motion Pro claims that its testing has proven the LiteLocs 10 to 20 percent stronger than conventional rim locks, despite being considerably lighter. I can’t substantiate that claim, but do know that most of the company’s principals and employees are avid offroad riders who rigorously test every product they develop. Given their excellent track record, I find it hard to argue with them.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontGreat Leaps

JUNE 2010 By Mark Hoyer -

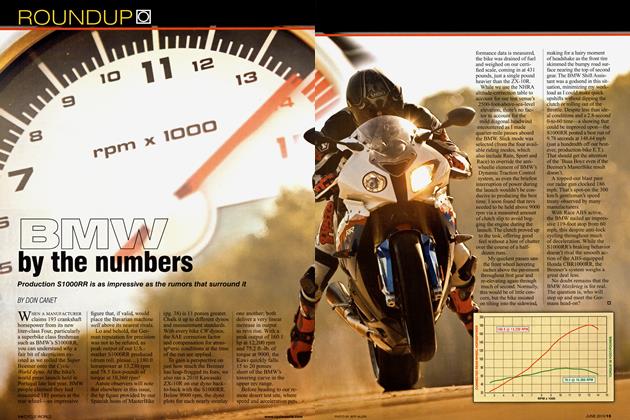

Roundup

RoundupBmw By the Numbers

JUNE 2010 By Don Canet -

Roundup

RoundupTeam Cycle World Is Going Racing!

JUNE 2010 By Matthew Miles -

Roundup

RoundupThe Way It Was

JUNE 2010 By Kevin Cameron -

Roundup

Roundup25 Years Ago June 1985

JUNE 2010 By Matthew Milles -

Roundup

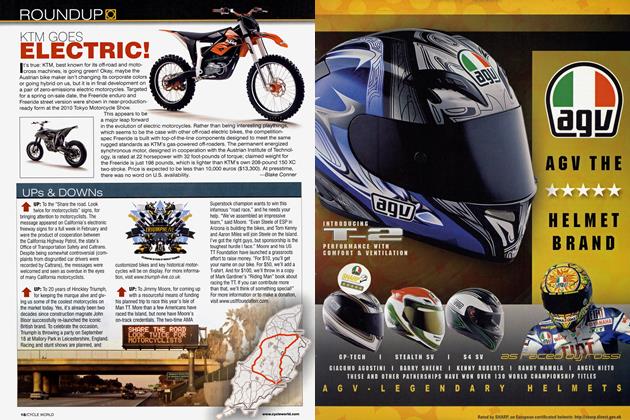

RoundupKtm Goes Electric!

JUNE 2010 By Blake Conner