Thrust

TDC

KEVIN CAMERON

TRACK DAY. You'RE OLD ENOUGH TO afford this bike, but not so old that you can't have the throttle fully open as soon as the front wheel's descent shows it's time. As the torque peak in the next gear arrives, there's a last lift.

These are pleasant moments. Be cause they require your full attention, they flush the mind clear of all the cares that press in upon us. This is 180-horse power yoga.

Peak torque, full throttle, is that point on the graph at which the balance of cylinder filling, combustion pressure, heat loss and friction give maximum effect—the maximum twisting force of which your engine is capable.

Holding yourself forward to keep the front wheel down enough to steer takes real muscular effort; you'll be sore to morrow. That will remind you to renew membership at the gym.

One basic variable in the thrust ac celerating your bike is the gear ratio. The lower the gear, the more leverage the engine's torque has over the rear wheel, which is why first gear is almost ridiculous because of the ease with which the front end comes up.

Primary gears, transmission gears, bearings and the chain all impose small friction taxes. It takes some power to wrap chain-under a literal ton of ten sion-tightly around the front sprocket. Your chain has 0-rings to keep its lu bricant where it belongs rather than being centrifuged out by the engine sprocket's 5000 rpm. Touch the chain when you stop immediately after a ses sion. It's hot. A kitchen toaster is 746 watts of heat. That's a horsepower.

The gears live in an oil storm, and it takes some power to squelch out excess oil as the teeth close. Pressure between teeth is grim-as high as 100,000 psi. And because gears combine rolling and sliding contact, even the slight slid ing has a cost at that kind of pressure. Check off roughly 2 percent per mesh and a bit more for the chain.

The tire is another tax: It costs some thing to be "hooked up." When the tire tech puts the needle into a top rider's rear tire, the readout says maybe 260 degrees F. It takes several horsepower

to keep that big piece of meat that far above boiling-water temperature, es pecially with an 80-mile-an-hour wind blowing on it.

Engine torque is directly propor tional to its net, stroke-averaged com bustion pressure. I say "net" because the piston, with roughly 1000 psi of combustion pressure pushing its top ring out against the cylinder wall, takes some shoving just to overcome its fric tion. And as the piston descends, the connecting rod angles over, pushing the piston hard against one side of the cylinder. The thin oil film on which it is sledding has to be viscous enough to resist squirting out and leaving dry, metal-to-metal contact behind it. And that viscosity is a drag on the piston. It can't be any other way.

Combustion pressure rises as the flame front spreads at 50 to 200 feet per second. Experience shows that maximum effect occurs when peak pressure is reached at 11 degrees after top dead center (ATDC). It is the job of the ignition map in your engine's ECU to vary the timing as necessary to achieve this. As you close the throttle, fuel and air molecules become farther apart and flame speed slows. That re quires earlier ignition. On cars back in the pre-computer era, that feature was called "vacuum advance."

The cylinder-filling ability of your en gine depends also on intake flow resis tance, cam timing and the state of wave action in the exhaust, intake and airbox.

Cam timing has always been a big compromise. To make power at higher revs, you'd like to close the intakes late, but at lower revs that lets the ris ing piston back-pump some of what the intake stroke has just let in. This is why

so many new car engines have variable cam timing. The length of the intake duct acts as an organ pipe, kept going by the engine's periodic big suctions on it. The idea is that the pressure wave banging back-and-forth should arrive at the valves just as they are closing. To broaden that effect, some engines have variable-length intakes.

The airbox, too, has a resonance, like the one you excite by blowing across the top of a bottle. After an engine suction event pulls airbox pressure down, fresh air rushes in its intake(s), pushing pres sure above atmospheric. Get this one in step and that high pressure will arrive just as the next intake event is ending. Free air equals free extra torque.

Exhaust waves are another part of peak torque. If the engineers have done it right, a negative pressure wave ar rives back at the exhaust valves around top center just after the exhaust stroke. Because the exhaust valves are still open a bit, that wave pulls residual ex haust out of the space above the piston and then gets the intake process moving before the piston begins its downstroke.

While combustion progresses, its hot, swirling gases lose heat to the piston crown and chamber walls. That makes it important that those surfac es have minimum area-not like the bad old days when wide valve angles meant deep combustion chambers with acres of extra heat-loss area in them. Today's chambers are almost flat. Yes, the larger bores in sportbike engines do increase heat-loss area. That's why car engines, designed for maximum econo my, have returned to smaller bores.

To enter the cylinder, fresh charge has to pass through an intake port that is hot enough to evaporate the fuel droplets it is carrying. But add any more heat than required for that task and the fresh charge begins to expand, losing density. That means a reduced charge and less torque. Engines used to be cooled by directing the cooled water from the radiator onto the hottest areas-the exhaust-valve seats and top of the combustion chamber. But that carries exhaust heat over to the intake side of the head, perhaps making it hot ter than it needs to be. More engines today are being designed the other way around-cooling the intake side first then the exhaust.

A lot of trial-and-error, moderated by thoughtful engineering, has all been made to add up to refreshing and mindclearing moments of rapid acceleration.

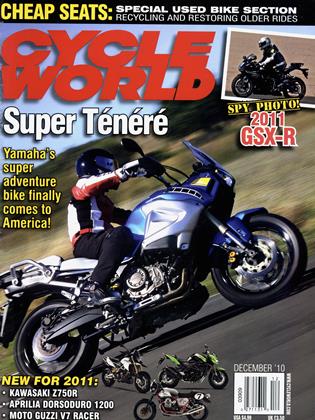

View Full Issue

View Full Issue

More From This Issue

-

Up Front

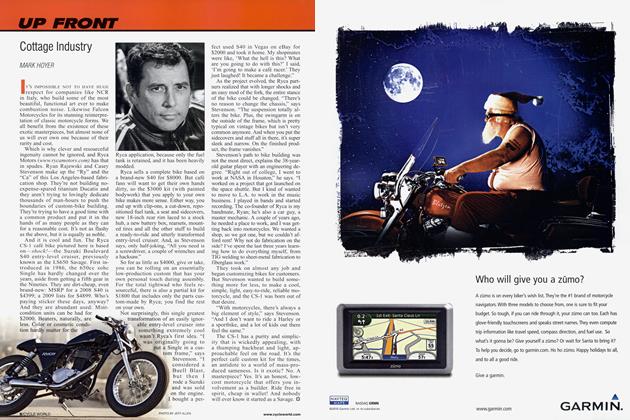

Up FrontCottage Industry

December 2010 By Mark Hoyer -

Roundup

RoundupHyde Harrier

December 2010 By Gary Inman -

Roundup

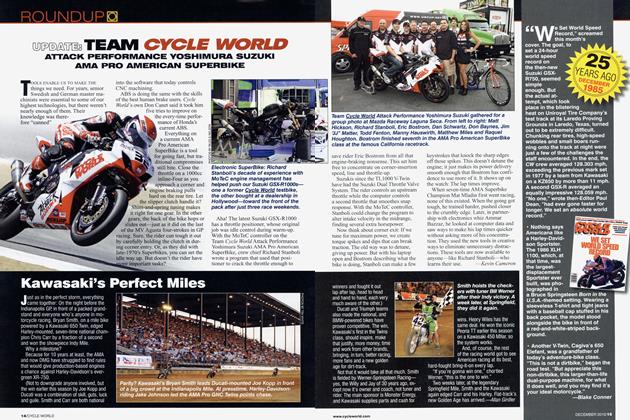

RoundupUpdate: Team Cycle World

December 2010 By Kevin Cameron -

Roundup

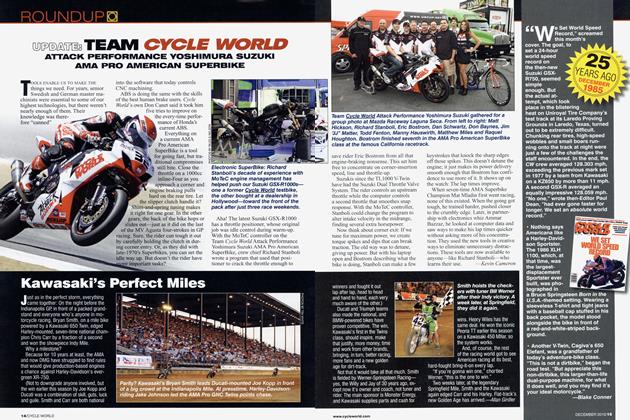

RoundupKawasaki's Perfect Miles

December 2010 By Allan Girdler -

Roundup

Roundup25 Years Ago December 1985

December 2010 By Blake Conner -

Roundup

Roundup2011: What's Just Over the Horizon?

December 2010 By Bruno Deprato, Matthew Miles