About 250s

TDC

KEVIN CAMERON

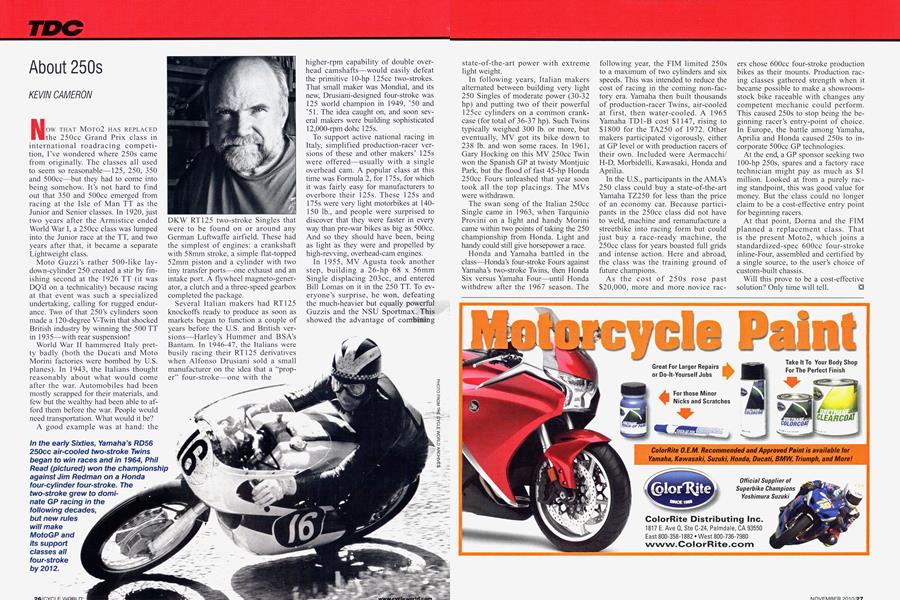

NOW THAT MOTO2 HAS REPLACED the 250cc Grand Prix class in international roadracing competition, I’ve wondered where 250s came from originally. The classes all used to seem so reasonable—125, 250, 350 and 500cc—but they had to come into being somehow. It’s not hard to find out that 350 and 500cc emerged from racing at the Isle of Man TT as the Junior and Senior classes. In 1920, just two years after the Armistice ended World War I, a 250cc class was lumped into the Junior race at the TT, and two years after that, it became a separate Lightweight class.

Moto Guzzi’s rather 500-like laydown-cylinder 250 created a stir by finishing second at the 1926 TT (it was DQ’d on a technicality) because racing at that event was such a specialized undertaking, calling for rugged endurance. Two of that 250’s cylinders soon made a 120-degree V-Twin that shocked British industry by winning the 500 TT in 1935—with rear suspension!

World War II hammered Italy pretty badly (both the Ducati and Moto Morini factories were bombed by U.S. planes). In 1943, the Italians thought reasonably about what would come after the war. Automobiles had been mostly scrapped for their materials, and few but the wealthy had been able to afford them before the war. People would need transportation. What would it be? A good example was at hand: the DKW RT125 two-stroke Singles that were to be found on or around any German Luftwaffe airfield. These had the simplest of engines: a crankshaft with 58mm stroke, a simple flat-topped 52mm piston and a cylinder with two tiny transfer ports—one exhaust and an intake port. A flywheel magneto-generator, a clutch and a three-speed gearbox completed the package.

Several Italian makers had RT125 knockoffs ready to produce as soon as markets began to function a couple of years before the U.S. and British versions—Harley’s Hummer and BSA’s Bantam. In 1946-47, the Italians were busily racing their RT125 derivatives when Alfonso Drusiani sold a small manufacturer on the idea that a “proper” four-stroke—one with the higher-rpm capability of double overhead camshafts—would easily defeat the primitive 10-hp 125cc two-strokes. That small maker was Mondial, and its new, Drusiani-designed four-stroke was 125 world champion in 1949, ’50 and ’51. The idea caught on, and soon several makers were building sophisticated 12,000-rpm dohc 125s.

To support active national racing in Italy, simplified production-racer versions of these and other makers’ 125s were offered—usually with a single overhead cam. A popular class at this time was Formula 2, for 175s, for which it was fairly easy for manufacturers to overbore their 125s. These 125s and 175s were very light motorbikes at 140150 lb., and people were surprised to discover that they were faster in every way than pre-war bikes as big as 500cc. And so they should have been, being as light as they were and propelled by high-revving, overhead-cam engines.

In 1955, MV Agusta took another step, building a 26-hp 68 x 56mm Single displacing 203cc, and entered Bill Lomas on it in the 250 TT. To everyone’s surprise, he won, defeating the much-heavier but equally powerful Guzzis and the NSU Sportmax. This showed the advantage of combining state-of-the-art power with extreme light weight.

In following years, Italian makers alternated between building very light 250 Singles of moderate power (30-32 hp) and putting two of their powerful 125cc cylinders on a common crankcase (for total of 36-37 hp). Such Twins typically weighed 300 lb. or more, but eventually, MV got its bike down to 238 lb. and won some races. In 1961, Gary Hocking on this MV 250cc Twin won the Spanish GP at twisty Montjuic Park, but the flood of fast 45-hp Honda 250cc Fours unleashed that year soon took all the top placings. The MVs were withdrawn.

The swan song of the Italian 250cc Single came in 1963, when Tarquinio Provini on a light and handy Morini came within two points of taking the 250 championship from Honda. Light and handy could still give horsepower a race.

Honda and Yamaha battled in the class—Honda’s four-stroke Fours against Yamaha’s two-stroke Twins, then Honda Six versus Yamaha Four—until Honda withdrew after the 1967 season. The following year, the FIM limited 250s to a maximum of two cylinders and six speeds. This was intended to reduce the cost of racing in the coming non-factory era. Yamaha then built thousands of production-racer Twins, air-cooled at first, then water-cooled. A 1965 Yamaha TD1-B cost $1147, rising to $1800 for the TA250 of 1972. Other makers participated vigorously, either at GP level or with production racers of their own. Included were Aermacchi/ H-D, Morbidelli, Kawasaki, Honda and Aprilia.

In the U.S., participants in the AMA’s 250 class could buy a state-of-the-art Yamaha TZ250 for less than the price of an economy car. Because participants in the 250cc class did not have to weld, machine and remanufacture a streetbike into racing form but could just buy a race-ready machine, the 250cc class for years boasted full grids and intense action. Here and abroad, the class was the training ground of future champions.

As the cost of 250s rose past $20,000, more and more novice racers chose 600cc four-stroke production bikes as their mounts. Production racing classes gathered strength when it became possible to make a showroomstock bike raceable with changes any competent mechanic could perform. This caused 250s to stop being the beginning racer’s entry-point of choice. In Europe, the battle among Yamaha, Aprilia and Honda caused 250s to incorporate 500cc GP technologies.

At the end, a GP sponsor seeking two 100-hp 250s, spares and a factory race technician might pay as much as $1 million. Looked at from a purely racing standpoint, this was good value for money. But the class could no longer claim to be a cost-effective entry point for beginning racers.

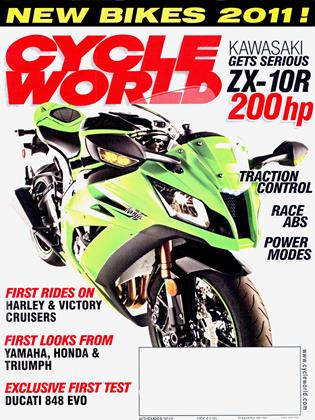

At that point, Dorna and the FIM planned a replacement class. That is the present Moto2, which joins a standardized-spec 600cc four-stroke inline-Four, assembled and certified by a single source, to the user’s choice of custom-built chassis.

Will this prove to be a cost-effective solution? Only time will tell. □

View Full Issue

View Full Issue

More From This Issue

-

Up Front

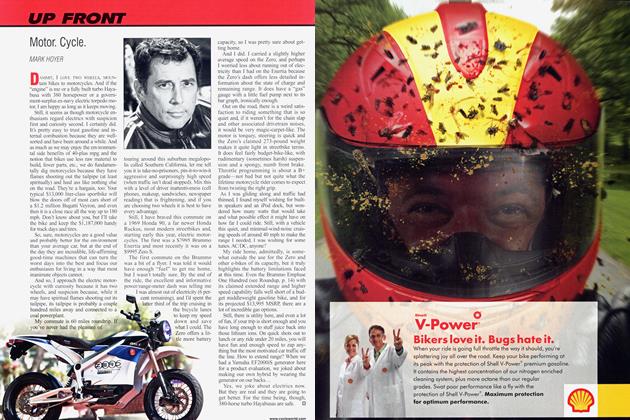

Up FrontMotor. Cycle.

November 2010 By Mark Hoyer -

Roundup

RoundupBuell Fights Back

November 2010 By Steve Anderson -

Roundup

RoundupItalian Triple Threat

November 2010 By Jeff Robert -

Roundup

RoundupUps & Downs

November 2010 -

Roundup

RoundupTeam Cycle World

November 2010 By Paul Dean -

Roundup

RoundupHeadbanger

November 2010 By Bruno Deprato