TECH TIPS

SERVICE

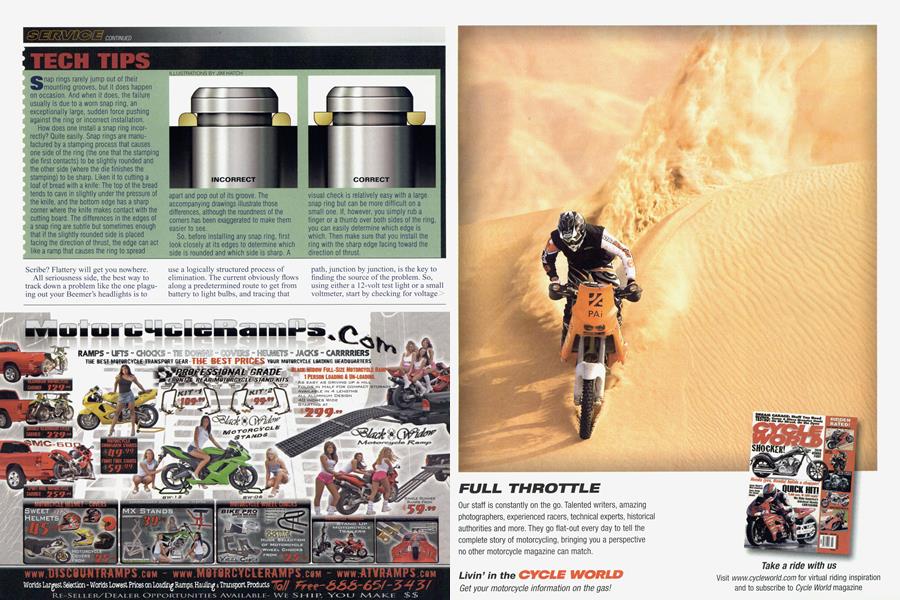

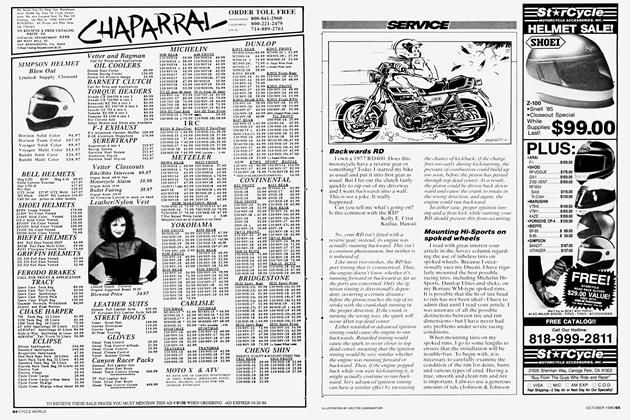

Snap rings rarely jump out of their mounting grooves, but it does happen on occasion. And when it does, the failure usually is due to a worn snap ring, an exceptionally large, sudden force pushing against the ring or incorrect installation.

How does one install a snap ring incorrectly? Quite easily. Snap rings are manufactured by a stamping process that causes one side of the ring (the one that the stamping die first contacts) to be slightly rounded and the other side (where the die finishes the stamping) to be sharp. Liken it to cutting a loaf of bread with a knife: The top of the bread tends to cave in slightly under the pressure of the knife, and the bottom edge has a sharp corner where the knife makes contact with the cutting board. The differences in the edges of a snap ring are subtle but sometimes enough that if the slightly rounded side is placed facing the direction of thrust, the edge can act like a ramp that causes the ring to spread

apart and pop out of its groove. The accompanying drawings illustrate those differences, although the roundness of the corners has been exaggerated to make them easier to see.

So, before installing any snap ring, first look closely at its edges to determine which side is rounded and which side is sharp. A

visual check is relatively easy with a large snap ring but can be more difficult on a small one. If, however, you simply rub a finger or a thumb over both sides of the ring, you can easily determine which edge is which. Then make sure that you install the ring with the sharp edge facing toward the direction of thrust.