Breakage

TDC

Kevin Cameron

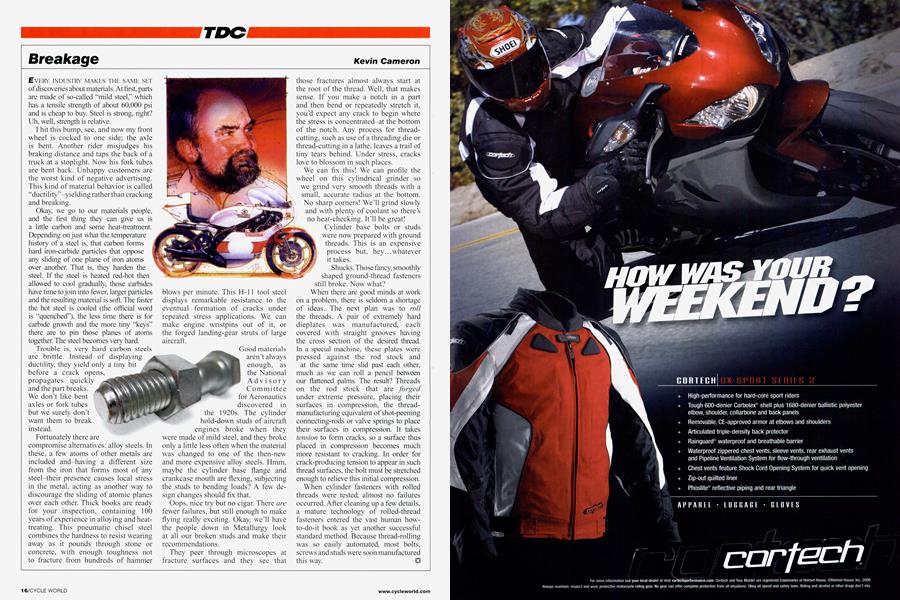

EVERY INDUSTRY MAKES THE SAME SET of discoveries about materials. At first, parts are made of so-called “mild steel,” which has a tensile strength of about 60,000 psi and is cheap to buy. Steel is strong, right? Uh, well, strength is relative.

I hit this bump, see, and now my front wheel is cocked to one side; the axle is bent. Another rider misjudges his braking distance and taps the back of a truck at a stoplight. Now his fork tubes are bent back. Unhappy customers are the worst kind of negative advertising. This kind of material behavior is called “ductility’-yielding rather than cracking and breaking.

Okay, we go to our materials people, and the first thing they can give us is a little carbon and some heat-treatment. Depending on just what the temperature history of a steel is, that carbon forms hard iron-carbide particles that oppose any sliding of one plane of iron atoms over another. That is, they harden the steel. If the steel is heated red-hot then allowed to cool gradually, those carbides have time to join into fewer, larger particles and the resulting material is soft. The faster the hot steel is cooled (the official word is “quenched”), the less time there is for carbide growth and the more tiny “keys” there are to pin those planes of atoms together. The steel becomes very hard.

Trouble is, very hard carbon steels are brittle. Instead of displaying ductility, they yield only a tiny bit before a crack opens, propagates quickly and the part breaks.

We don’t like bent axles or fork tubes but we surely don’t want them to break instead.

Fortunately there are compromise alternatives: alloy steels. In these, a few atoms of other metals are included and-having a different size from the iron that forms most of any steel-their presence causes local stress in the metal, acting as another way to discourage the sliding of atomic planes over each other. Thick books are ready for your inspection, containing 100 years of experience in alloying and heattreating. This pneumatic chisel steel combines the hardness to resist wearing away as it pounds through stone or concrete, with enough toughness not to fracture from hundreds of hammer

blows per minute. This H-l 1 tool steel displays remarkable resistance to the eventual formation of cracks under repeated stress applications. We can make engine wristpins out of it, or the forged landing-gear struts of large aircraft.

Good materials aren’t always enough, as the National Advisory Committee for Aeronautics discovered in the 1920s. The cylinder hold-down studs of aircraft engines broke when they were made of mild steel, and they broke only a little less often when the material was changed to one of the then-new and more expensive alloy steels. Hmm, maybe the cylinder base flange and crankcase mouth are flexing, subjecting the studs to bending loads? A few design changes should fix that.

Oops, nice try but no cigar. There are fewer failures, but still enough to make flying really exciting. Okay, we’ll have the people down in Metallurgy look at all our broken studs and make their recommendations.

They peer through microscopes at fracture surfaces and they see that

those fractures almost always start at the root of the thread. Well, that makes sense. If you make a notch in a part and then bend or repeatedly stretch it, you’d expect any crack to begin where the stress is concentrated-at the bottom of the notch. Any process for threadcutting, such as use of a threading die or thread-cutting in a lathe, leaves a trail of tiny tears behind. Under stress, cracks love to blossom in such places.

We can fix this! We can profile the wheel on this cylindrical grinder so we grind very smooth threads with a small, accurate radius at the bottom. No sharp corners! We’ll grind slowly and with plenty of coolant so there’s no heat-checking. It’ll be great!

Cylinder base bolts or studs were now prepared with ground threads. This is an expensive process but, hey...whatever it takes.

Shucks. Those fancy, smoothly shaped ground-thread fasteners still broke. Now what?

When there are good minds at work on a problem, there is seldom a shortage of ideas. The next plan was to roll the threads. A pair of extremely hard dieplates was manufactured, each covered with straight grooves having the cross section of the desired thread. In a special machine, these plates were pressed against the rod stock and at the same time slid past each other, much as we can roll a pencil between our flattened palms. The result? Threads on the rod stock that are forged under extreme pressure, placing their surfaces in compression, the threadmanufacturing equivalent of shot-peening connecting-rods or valve springs to place their surfaces in compression. It takes tension to form cracks, so a surface thus placed in compression becomes much more resistant to cracking. In order for crack-producing tension to appear in such thread surfaces, the bolt must be stretched enough to relieve this initial compression.

When cylinder fasteners with rolled threads were tested, almost no failures occurred. After cleaning up a few details, a mature technology of rolled-thread fasteners entered the vast human howto-do-it book as yet another successful standard method. Because thread-rolling was so easily automated, most bolts, screws and studs were soon manufactured this way.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

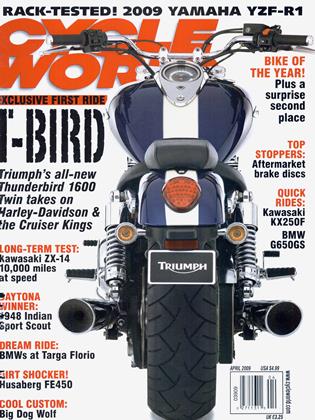

Up FrontBike of the Year

April 2009 By David Edwards -

Leanings

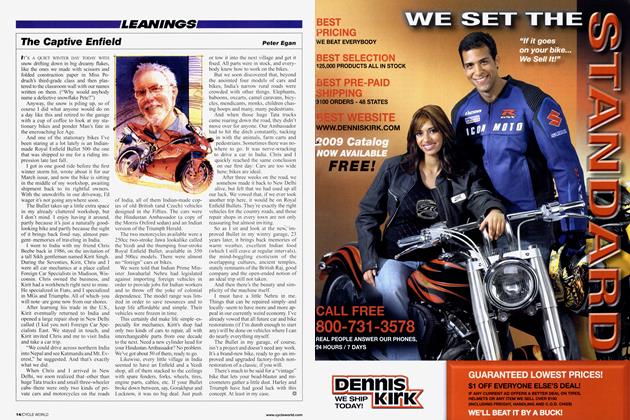

LeaningsThe Captive Enfield

April 2009 By Peter Egan -

Departments

DepartmentsHotshots

April 2009 -

Roundup

RoundupCall of the Wild

April 2009 By Mark Hoyer -

Roundup

RoundupCustoms Live: Reports of Hot-Rodding's Demise Have Been Greatly Exaggerated

April 2009 By Paul Dean -

Roundup

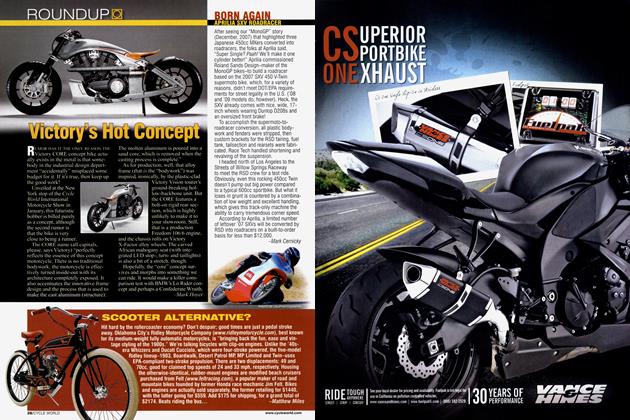

RoundupVictiry's Hot Concept

April 2009 By Mark Hover