TECH TIPS

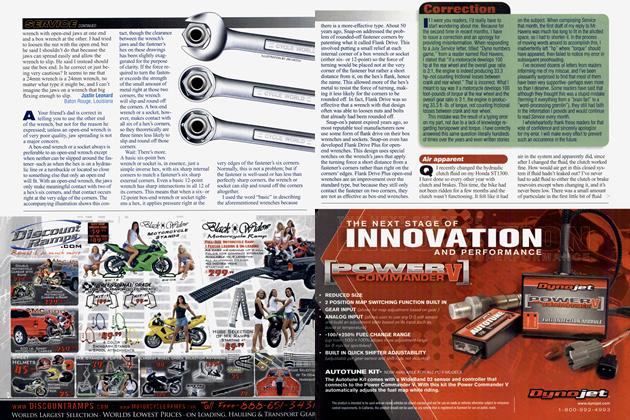

There are numerous ways to prevent fasteners from loosening or falling off a motorcycle. Applying Loctite or other thread lockers is one method, and using any of several different types of locking nuts is another. But thread locker can make removing the fastener difficult and, in the process, possibly damage the threads in softer metals, and lock nuts are not an option on bolts or screws that fit into threaded holes. One of the most versatile and least intrusive methods of securing fasteners, though, is to safety wire them. Properly done, safety wiring not only guarantees that the nut, bolt or

screw won’t fall out, it ensures that the fastener can’t even loosen.

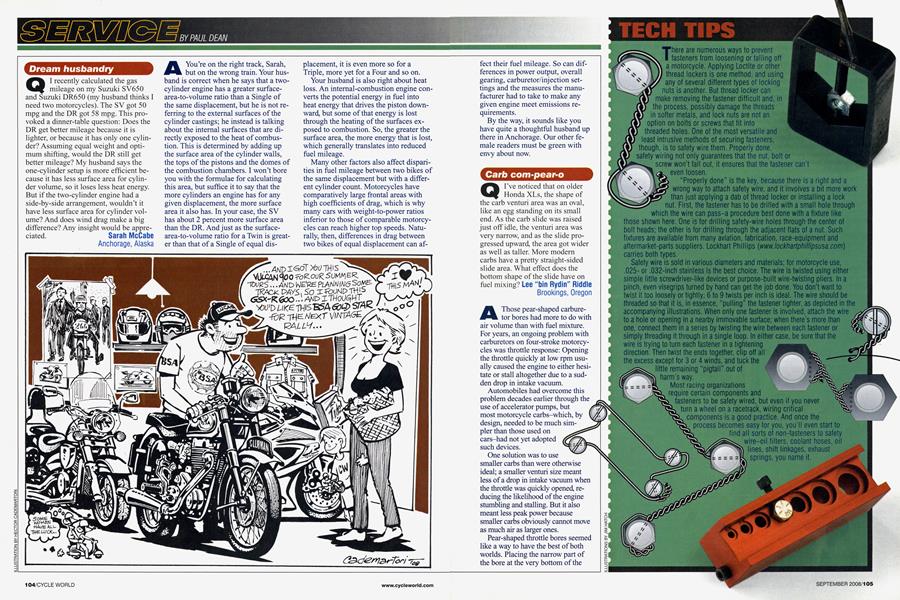

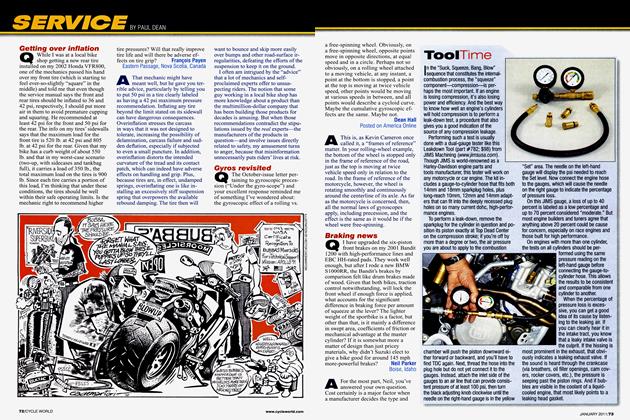

“Properly done” is the key, because there is a right and a wrong way to attach safety wire, and it involves a bit more work than just applying a dab of thread locker or installing a lock nut. First, the fastener has to be drilled with a small hole through which the wire can pass-a procedure best done with a fixture like those shown here. One is for drilling safety-wire holes through the center of bolt heads; the other is for drilling through the adjacent flats of a nut. Such fixtures are available from many aviation, fabrication, race-equipment and aftermarket-parts suppliers. Lockhart Phillips (www.lockhartphillipsusa.com) carries both types.

Safety wire is sold in various diameters and materials; for motorcycle use,

.025or .032-inch stainless is the best choice. The wire is twisted using either simple little screwdriver-like devices or purpose-built wire-twisting pliers. In a pinch, even visegrips turned by hand can get the job done. You don’t want to twist it too loosely or tightly; 6 to 9 twists per inch is ideal. The wire should be threaded so that it is, in essence, “pulling” the fastener tighter, as depicted in the accompanying illustrations. When only one fastener is involved, attach the wire to a hole or opening in a nearby immovable surface; when there’s more than one, connect them in a series by twisting the wire between each fastener or simply threading it through in a single loop, in either case, be sure that the wire is trying to turn each fastener in a tightening direction. Then twist the ends together, clip off all the excess except for 3 or 4 winds, and tuck the little remaining “pigtail” out of harm’s way.

Most racing organizations require certain components and fasteners to be safety wired, but even if you never turn a wheel on a racetrack, wiring critical components is a good practice. And once the process becomes easy for you, you’ll even start to find all sorts of non-fasteners to safety wire-oil filters, coolant hoses, oil lines, shift linkages, exhaust springs, you name it.