SERVICE

PAUL DEAN

Holy hooligans

Ql’m cle in 63, 1966 bought and my have first read motorcymultiple bike magazines every month ever since. I’ve ridden many miles and met lots of bikers of every kind, but I must have missed the issue in which the terms “hooligan bike” and “streetfighter” were coined. Can you shed some light for me? Mike Riley

Monroe, Louisiana

A Those terms originated in England sometime in the late 1980s or early 1990s, if I’m not mistaken. The fully faired sportbike revolution was well under way, and enough machines of that type had been thrown down the road by then to provide a fairly large supply of mechanically sound but cosmetically trashed performance bikes. Some enthusiastic-and often cash-strapped-blokes who either bought or already owned such damaged machines decided to strip off what was left of their bikes’ bodywork, graft on tubular handlebars and mount the headlights one way or another. The impressive engine and chassis performance of those bikes would remain unaffected, resulting in sit-upright machines ideal for strafing the streets of London and other metropolitan areas. This bad-boy behavior led to motorcycles of that ilk earning the “hooligan bikes” name in some circles and “streetfighters” in others. The movement even spawned a magazine, called Streetfighters, dedicated to bikes of this type.

Matter of fact, the impetus for most of the high-performance naked bikes on the market today-Aprilia Tuono, Ducati Monster, Yamaha FZ1 and especially the Triumph Speed Triple-came from the streetfighters phenomenon. These latter-day ’fighters may not have followed the original formula to the letter, but they certainly have carried it out in spirit.

Snakes in the brakes

Ql’ve on the seen market a couple that of claim products to give any bike’s hydraulic brake system antilock properties. They don’t cost much, and they appear to be little aluminum modules that connect to a brake line or a caliper. I’ve even seen similar items on some small bikes made in China. Are these things legit? Do they really work or are they just another form of “snake oil”? Donald James

Elyria, Ohio

AI don’t believe any snakes were harmed in the making of these devices, but they definitely do not give a brake system anti-lock capabilities. What they do provide is a spongy pedal or lever that makes the brake harder to lock up. The interior of these gadgets is simplistic, consisting of a chamber that’s plumbed into a brake line and a compressible media of some type, usually rubber. When the rider applies lever or pedal pressure to the braking system, an equal pressure is present in the chamber. That pressure compresses the rubber, requiring the rider to squeeze the lever or push the pedal even farther to reach the desired level of braking. The net effect is to make the brake much less sensitive by increasing the amount of lever/pedal travel needed to make the bike slow down or stop.

This is far from a new invention. Widgets of this type first appeared decades ago but soon vanished as people discovered that they were more harmful than helpful to overall braking performance.

Buzzkill

Ql’ve since been 1969 riding and have continuously owned too many bikes to count, but I’ve always had a problem with an inlineFour’s buzz. Since 1995, I’ve found Hinckley Triumph’s Triples and Twins to be most agreeable with their counterbalancer arrangements. Recently, however, I’ve pondered something I can’t answer: Inline-Fours typically have their crankshaft throws at 180 degrees in the traditional two-up, twodown arrangement. Why not make an inline-Four with a 90-degree crank? Left to right, each cylinder’s rod journal would be 90 degrees advanced of the previous one. Then, using a single counterbalancer, counter-weight the rotation as Hinckley does its 120degree triple. This layout would also seem to provide ideal exhaust gas scavenging. There is probably a glaring reason why they maintain the traditional firing order but I thought I’d just ask. Kenneth Thompson

Manhattan Beach, California

A Glaring, indeed. Your idea is an interesting one, but you overlooked one critically important fact: A four-stroke engine requires two full revolutions of the crankshaft (720 degrees) to complete one power cycle for all cylinders. Divide 720 by 4 and you get 180 degrees, the crank-throw spacing necessary to achieve even firing intervals.

With your 90-degree crank, however, an equally spaced firing order would not be possible. No matter how you might phase the firing, you end up with some combination of 90-, 180and 270-degree intervals. We know that most inline-Four MotoGP bikes, including Valentino Rossi’s Yamaha, have been built with various uneven firing intervals in the search for better tractability; what we don’t know is the kind of accompanying engine-balancing technology required to make such a configuration suitably smooth or how it might serve the needs of streetbike riders. The “flat” inline-Four crank has its drawbacks, primarily in the area of vibration, but it has proven for decades to be the best overall arrangement for engines of that cylinder layout.

Compression expression

QI want to know more about

compression ratios. I am guessing, based on the format of the numbers ( 10.5:1, for example), that they are a measure of the pressure in the cylinder in psi when the piston is at TDC compared to the pressure at BDC. Is that close? Can you explain more about these ratios and how they relate to engine performance? Brandon Wyatt Lancaster, California

A Although compression ratio does have a direct effect on cylinder pressure, compression-ratio numbers are not a measure of that pressure. They instead are a comparison of the volume inside a cylinder when the piston is precisely at Top Dead Center and the volume at Bottom Dead Center. If, say, the TDC volume is 55cc and the BDC volume is 550cc, the compression ratio would be 10.0:1 (550-55=10).

Higher compression ratios generally yield bigger torque and horsepower numbers simply because the piston is squeezing a given amount of air-fuel mixture into a smaller space before igniting it. The rapid expansion of the burning mixture in that smaller volume creates a greater cylinder pressure higher in the piston’s downward travel. This translates to increased leverage on that cylinder’s crankshaft throw, which in turn means more torque at the drive end of the crank.

With rare exception, engines running on pump gasoline are limited to compression ratios no higher than 13.0:1. If the ratio is much higher, the heat generated by compression will ignite the fuel before the spark has a chance to do so, resulting in pre-ignition and detonation (pinging) that can damage the engine.

Diesel engines, however, have no ignition systems, instead igniting the fuel via that very same principle, called compression ignition. In modern dieseis, the pistons compress only air in the cylinders; direct injection then squirts atomized diesel fuel into the cylinders at the last millisecond, just in time for the hot compressed air to ignite it. As a consequence, diesels can have compression ratios that run as high as 25.0:1.

Values that suck

QIn the July issue, you provided us with a very understandable explanation of five-valve cylinder heads (“Four is more than five”). Is there any chance you could explain what is meant by “atmospheric valves,” like the ones used in the Harley-Davidson Silent Grey Fellow first produced in 1906? George Picabea Sugar Hill, Georgia

A Many early four-stroke engines, including those used by H-D during its first few years of production, did not operate their intake valves with camshafts. Instead, the intakes were held closed only by a very soft spring and opened solely by the suction of the piston descending on the intake stroke. Once the piston passed Bottom Dead Center and began ascending, the compression stroke, coupled with the weak spring, closed the valve, and the pressure of combustion kept it closed until the next intake stroke.

Engines with atmospheric valves were limited to very low rpm levels, a fact that soon led Harley-Davidson to switch to camshaft-operated intakes. Motorcycles were not alone in using this style of intake-valve operation, either. Numerous automobiles of the early 20th century had atmospheric valves, and quite a few simplistic industrial engines continued to employ that design for many decades thereafter.

Not the liquid of choice

QI recently read an article in a car magazine that mentioned in passing that the presence of water in a hydraulic braking system could cause total brake failure, but the article did not explain why. I’m aware that a liquid cannot be compressed, which one of the principles that allow brake systems to function, but water and brake fluid both are liquids, so why would water in the system cause the brakes to fail? Davey Simone Las Cruces, New Mexico

A Because of heat. When a caliper pinches a brake rotor, the resultant friction generates heat, much of which makes its way to the brake fluid via the pads and pistons. If the vehicle must make repeated stops in a short period of time or the brakes are in constant use on a long downhill, the amount of heat the fluid must withstand is enormous. Most brake fluids have a boiling point in excess of 400 degrees Fahrenheit, with some high-performance types rated as high as 600 degrees. Water, however, boils at around 212 degrees, a temperature than can easily be exceeded in a brake system. When a liquid boils, it turns to vapor, meaning it is no longer a non-compressible liquid but instead is an easily compressible gas. If only a tiny amount of water vapor is present in the system, the brakes just get spongy; but if there is a large amount, the brakes will go away altogether. When the latter occurs, there is practically no resistance as you squeeze the lever or push on the pedal because most of the force you are applying is simply compressing the water vapor. Full braking usually returns when the vapor cools and reverts to its liquid state, but that may be too late to prevent a crash.

There are other problems associated with the presence of water in a braking system, such as corrosion and a lack of the important lubrication that brake fluid provides. But far and away, the most serious potential problem is the complete loss of braking capabilities. □

Got a mechanical or technical problem with your beloved ride? Can’t seem to find workable solutions in your area? Or are you eager to learn about a certain aspect of motorcycle design and technology? Maybe we can help. If you think we can, either: 1) Mail a written inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/631 -0651 ; 3) e-mail it to CW1Dean@aol.com; or 4) log onto www.cycleworld.com, click on the “Contact Us” button, select “CW Service” and enter your question. Don’t write a 10-page essay, but if you’re looking for help in solving a problem, do include enough information to permit a reasonable diagnosis. And please understand that due to the enormous volume of inquiries we receive, we cannot guarantee a reply to every question.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontElectric Chair

February 2008 By David Edwards -

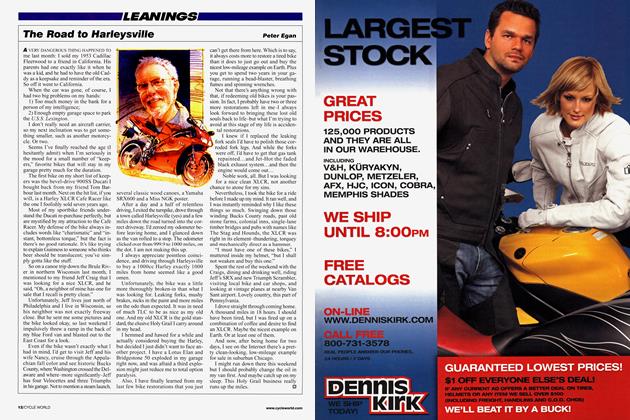

Leanings

LeaningsThe Road To Harleysville

February 2008 By Peter Egan -

TDC

TDCControlled Motions

February 2008 By Kevin Cameron -

Departments

DepartmentsHotshots

February 2008 -

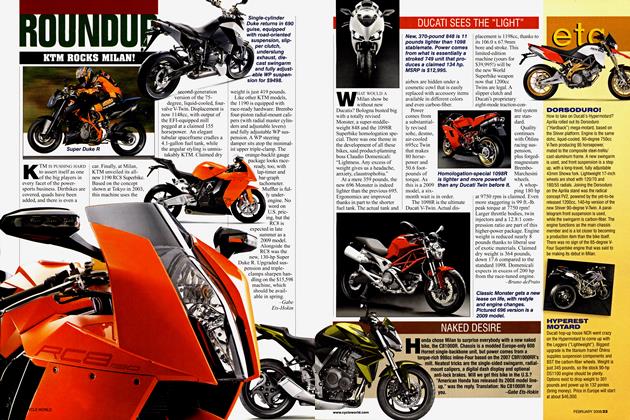

Roundup

RoundupKtm Rocks Milan!

February 2008 By Gabe Ets-Hokin -

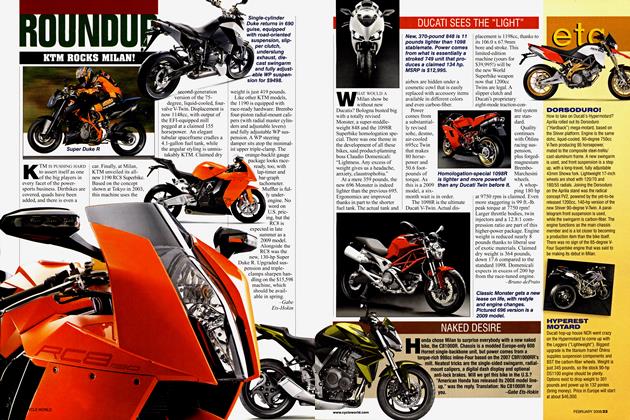

Roundup

RoundupNaked Desire

February 2008 By Gabe Ets-Hokin