SERVICE

PAUL DEAN

Which meter is neater?

QI have a question about motorcycle electrical systems. My car has an ammeter on the dashboard, and my truck has a voltmeter, but most bikes these days have neither. I think it’s stupid not to have one or the other on a motor vehicle, but I’m not sure which is better. In your opinion, which is more useful, an ammeter or a voltmeter?

Kelly Whitmore

Grand Junction, Colorado

Ain a perfect world, all motor vehicles with internal-combustion engines would have both. An ammeter tells you how much charging current is being delivered to the battery, but it doesn’t reveal the battery’s voltage. So, even when an ammeter shows a good charging rate, thereby indicating that the alternator and regulator are functioning properly, the battery nevertheless might not be able to hold the charge.

Conversely, a voltmeter informs you of the voltage in the vehicle’s electricals (or in the battery itself if the engine is not running), but it doesn’t let you know if charging current is being delivered to the battery. So, while a voltmeter may indicate that there is an adequate amount of voltage available to power the electrical components, the charging system may not be functioning at all and the meter’s reading would only be indicative of the battery’s voltage at that given moment. That’s why the ideal setup would be to have both meters.

In retrospect, I want to recant my first statement. In a truly perfect world, batteries would never go dead, charging systems would never fail and electrical components would never, ever malfunction. In an environment like that, there would be no need for either a voltmeter or an ammeter.

Looking for Mr: Neutral

QWhen I try to start my ’97 Kawasaki ZX-9R after it sits for two or three days, I can turn the key and thumb the start button but the engine won’t turn over until I jiggle the shift lever. After it starts and I ride for a bit, the problem goes away. I have replaced the neutral switch and the clutch switch but neither has cured the problem. Please help; this has become awfully annoying.

Robert A. Betts Posted on www.cycleworld.com

A Sounds like your Kawasaki has a problem with the spring on the detent arm, which is the part of the shifting mechanism that holds the shift drum in each gear position, including neutral. When you shift into neutral, a claw-like pawl on the shift shaft rotates the drum almost all the way into neutral, then the spring tension of the detent arm finishes

the job. But if the spring has weakened over time, it won’t have enough strength to move the shift drum those last few degrees, preventing the little electrical contact on the drum from aligning with the neutral switch on the engine cases. Then, when you jiggle the shift lever, the claws of the pawl make just enough contact with the drum to bump it the rest of the way.

It’s entirely possible, of course, that other factors might be contributing to this misalignment. If the engine oil is dirty or of too heavy a viscosity, for example, it can cause the shift drum to be just sluggish enough in its rotation not to fully index in the neutral position when the engine is cold. Once the engine warms up, the oil thins out enough to let the drum rotate more freely, so the problem temporarily goes away.

There also could be problems with the shift shaft. If the hairpin spring on the shaft is weak, or if the shifter pawl has gotten out of adjustment, either condition could prevent the shift drum from indexing properly in neutral; when that happens, however, there usually are problems with other gears, such as missed shifts and the transmission jumping out of gear. You did not report any such symptoms, so I suggest you merely replace the detent spring, which-like the rest of the shifting mechanism-is accessible behind the clutch.

Undercut? Underdogs?

Q About two years ago, Cycle World ran an article on a 919 Honda that was built by Erion Racing. In the article you mentioned that the transmission had “undercut” gears that made it shift very positively. I am wondering exactly what this upgrade is (if it is an upgrade), and what the procedure is to get it done. I bought a 919 after reading the article and have been tweaking it ever since. I still do not like the way it shifts and am wondering if this would help. I’m comparing it to my FJR, so maybe it will never shift like that bike, but anything will help.

Mike Davis Mukwonago, Wisconsin

A When motorcycle people talk about “undercut gears,” what they actually are referring to are undercut gear dogs. These are the squarish pegs on the sides of adjacent transmission components that engage one another when one of those components is slid sideways on its shaft during a gearchange. Undercut gears, on the other hand, describes a type of gear-tooth profile that has nothing to do with shifting and is not relevant to this topic.

Tool Time

Sometimes you need a Vinch-drive ratchet.

Sometimes a 1/4-inch-drive is preferable. Some situations call for a shorthandled ratchet. Others would be best served by one with a different-length handle-but not too long and not too Hmm. Sounds like you need an entire fleet of ratchets, right?

Not necessarily. Not if you have the Dual Drive Extendable ratchet from Powerbuilt. This clever tool has a Vinch-square-drive stud on one side and a 1/4-inch mate on the other. This is an eminently logical use of a ratchet’s backside, since it doesn’t do anything but just be there. You gotta wonder why no one thought of this before. So no matter if you’re working with 3/8or Vá-inch sockets, this one ratchet gets the job done.

Oh, and the handle length? The Powerbuilt has that, uh, “handled,” too. By just raising the little knurled collar at the top of the rubberized grip, you can adjust the ratchet’s steel shaft to any of four lengths, then release the collar to lock the shaft in place. This gives you a single ratchet that can be 61/z, VA, 8 or 8% inches in length. Not only that, the ratchet mechanism has very fine teeth so that every few degrees of handle movement catches the next tooth, which is ideal for working in tight spots.

Powerbuilt is based in New Zealand, but their tools are available at many retail outlets in the U.S., including Pep Boys (where I bought mine), Orchard Supply Hardware, Kragen/Checker/Schucks Auto Parts and Tractor Supply Company. The part number for the Dual Drive Extendable is 940926, and the retail price is $19.95. As part of a take-along toolkit or a toolbox in a home garage, this ratchet is a useful, one-sizefits-all addition.

Then there’s the matter of all the various head types currently found on nuts and bolts. When working on any given vehicle or other mechanical device, you’re likely to encounter fasteners with 6-point, 12-point,

Torx, Square or Spline-style heads, most of which require a different type of socket for proper removal and installation.

Mac Tools has come up with a practical solution in the form of its 6-in-1 Spherical Sockets. These sockets have a unique, patented design that uses 12 widely spaced “ribs” to contact the driving surfaces of the aforementioned fasteners, allowing each socket to be compatible with all five fastener styles. So rather than needing to have a sea of various sockets in your toolbox, you can limit the inventory down to, say, a small lake.

But wait! They’re called “6-in-1.” What’s the sixth application? Well, if a fastener has gotten rounded off but still has more than 50 percent of its contact surfaces remaining, there’s an excellent chance that a Spherical Socket will remove it.

At present, these sockets are available only in SAE (American) sizes in a rather expensive 15-piece 1/z-inch-drive deep-well set (part #SVD15BR, $329.99) or a more reasonably priced 13-piece 3/8-inch-drive shallow socket set (part #SX13SBR,

$129.99). Mac also sells ratcheting box-end Spherical Wrenches in both SAE and metric sizes, and plans to introduce metric Spherical Sockets very soon. You can purchase these tools from Mac distributors (who travel from repair shop to repair shop in marked trucks) everywhere. If you don’t know how to contact your local distributor, just call 800/MACTOOLS and ask.

In some transmissions, as illustrated here, the engagement dogs are on the sides of the gears. In other transmissions, the dogs (or in yet other designs, the slots that the dogs engage with) are on separate, smaller sliding rings that are much lighter than complete gears, which can help the transmission shift with less rider effort. Whatever the case, most dogs have straight sides as seen in the illustration within the circle. But if you look at the larger illustration, you’ll see that the dogs are tapered so they’re slightly wider at the outer edges than at the base. Those are undercut dogs.

Here’s why they are cut that way:

As a shift is begun, the two sets of dogs for the gear that is being selected are moving at considerably different speeds, so there is a forceful collision when they engage. Over time, those constant impacts tend to round the edges of the dogs-especially if the dogs are straight and the bike is involved in racing, or if the rider habitually executes sloppy or full-throttle shifts. Soon, the edges get so rounded that the dogs start rejecting one another before they can fully engage-a missed shift, in other words. The longer that condition goes uncorrected, the greater the frequency of missed shifts.

This is where undercutting comes in. By making the engagement dogs wider on the outer ends than at their base, the dogs act like ramps that draw the two components together. Not only does this deter rejection, it often causes the gears to complete the last part of the shift practically on their own. And as long as the engine is driving the rear wheel or vice versa, the forces acting on the ramps hold the engaged dogs firmly together.

A potential downside to undercutting takes place during the very early part of a gearchange-the part where engaged dogs have to be drawn apart so a different set can be slid together. The ramps then work in reverse, tending to hold the gears together and offer resistance to the shifting process. For this reason, undercutting cannot simply be done haphazardly; too much and the transmission will be even harder to shift, too little and there will be no improvement.

Quite a few modern sportbikes come from the factory with undercut gears, and several companies in the aftermarket perform undercutting services. Drag racers often prefer to undercut only the sides of the dogs that are loaded during acceleration, while roadracers usually want both sides beveled. Gear dogs that already are rounded off usually cannot be undercut, however; so if a transmission is wellworn or has been missing shifts, it is likely to need new gears and/or dogs before any undercutting is performed. I don’t know the condition of your 919’s transmission or how poorly it shifts, so I can’t assure you that undercutting would help. It probably would, but only you can decide if the $500-700 it would cost to have the work done would be worthwhile.

Candid Cameron

QAre variable the few valve manufacturers timing on motorcythat use cle engines simply advancing or retarding the cams, or is there some way to change the duration and lift of the valves? If there is a way of changing the duration while the engine is running, how does it work?

Don Hestand Grandview, Texas

A Independently and continuously variable lift and timing is the holy grail, but mechanical realities have compelled the world to accept simpler substitutes. Cam-phase changers are now on a lot of auto engines and work by axially sliding one element of a helical coupling, either hydraulic or electrical.

As outlined in the sport-touring comparison elsewhere in this issue, Honda’s VTEC system on its Interceptor V-Four operates two of four valves (one intake, one exhaust) in each cylinder, then switches by means of a hydraulically energized peg to operate both intakes via a forked rocker. Cutting intake area in half at lower rpm yields a higher intake speed than would occur if both valves were opening. Kawasaki’s new Concours 14, also described in this issue, uses a computer-controlled, hydraulically powered regulator to alter the intake cam’s timing.

Mikuni has shown a variable-lift system but I don’t think it is in use. GM did a big study many years ago of what engines would be like if they were throttled by variable valve lift, but it only involved lab-grade hardware. Interestingly, the 1901 Mercedes that was such a pioneering design in many respects also used this feature.

I think the industry right now is seeing what it can do with electronics before it tackles new mechanical solutions. BMW has a hydraulic variable-timing system for its cars but it has a comparatively low upper rpm limit. A company called Aura has made an electromagnetic system but it, too, has not gone into production. There are other such systems in development, so I expect we’ll see something of the kind fairly soon. -Kevin Cameron

Spec-ulation

QI was browsing through Buell’s website and noticed that the seat heights listed on their spec sheets are measured with the rider already on board. Is this how all manufacturers measure their bikes’ seat heights or is it just Buell? Ralph Badrina

Berwyn, Illinois

A Frankly, we aren’t always sure

how most manufacturers measure anything. The dimensions we carefully measure here on some testbikes aren’t even close to those that appear on the bike’s spec sheet.

Whether to measure seat height with the bike laden or unladen is a conundrum. On one hand, taking the measurement with a rider aboard will produce a lower dimension than unladen simply because the suspension is compressed.

But that then prompts the question: How much does the rider weigh? Obviously, a 100-pound rider won’t compress the suspension-or the seat foam, for that matter-anywhere near as far as a 250-pounder would; so for the lighter rider, that dimension would be meaningless at best and misleading at worst.

On the other hand, measuring seat height with the bike unladen at least provides consistent data for every concerned individual. Riders first have to get on the bike before worrying about whether or not they can touch the ground from the saddle, and a tall unladen seat can make climbing aboard a very difficult, precarious proposition for a small/short-legged person. Seat width also can be a factor; wide seat can make it more difficult for the rider to get both feet on the ground than a narrower seat of the same height.

In the end, the only way for anyone to know the true effect of any bike’s seat height is to try it first-hand. That’s a question best answered in the showroom.

R1 throttle response

I have a major problem with my 2007 Yamaha Rl. If I hold the

rpm at around 5500 in second gear and then nail the throttle, nothing happens. Nothing. There is no response at all for 3 or 4 seconds, then the bike accelerates fairly slowly at first. It does this every time. Yamaha says there is no such problem, but every ’07 RI I know of does this same thing. There even is a dedicated R1 forum where many owners of these bikes report having the same throttle glitch. Trust me, this is annoying at best, dangerous at its worst.

Feedback Loo

Q

Your answer to Jason Miller’s question (“Reverse engineering,” July issuej regarding the universally accepted layout tor transverse inline motorcycle engines (exhaust in front, intake rear) omitted the primary reason for this design. When all motorcycle engines were air-cooled, it was critical that the engine be positioned where the exhaust-valve side of the head would receive the cleanest and coolest airstream possible. This necessitated the exhaust exit from the front of the engine. With the arrival of production liquid-cooled engines, maintaining this layout has more to do with style than substance. Routing the exhaust under the seat has not been a major issue with any number of V-Four configurations, the Yamaha V-Max and Flonda VFR coming to mind. The main issue is that except for sportbikes, the engine looks more “normal” with the exhaust exiting from the front.

With fully covered sportbikes, it would make a lot more sense to reverse the head and put the intakes in the front. By running the intakes through the top of the head (Ford Indy engine style), the injectors would easily clear the frame and allow ample room for the airbox.

This would also allow the engine to be moved forward 3-4 inches, putting more weight on the front tire. As for underseat heat, based on the current crop of sportbikes, it appears Suzuki is the only manufacturer that considers this a major problem. Richard Koch

Keller, Texas

A You make a couple of good points, Richard, but cylinder-head technology has come a long way since the 1960s and the Ford Indy engine. I’m not sure the bike manufacturers would be able to extract as much performance-and achieve the requisite emissions compliance-from that design as they now do with current heads. They don’t use that style of intakes on their MotoGP engines, and that alone tells me volumes.

What’s more, Suzuki did not eschew under-seat exhausts for reasons of heat. During development of the newer GSX-Rs, the test riders reported that the higher and morerearward weight of under-seat exhausts had negative effects on the bikes’ flickability into turns and through side-to-side transitions.

Besides, on the other sportbikes you refer to, the only part of the entire exhaust system that passes beneath the rider’s seat are the pipes that lead from the under-engine collector to the under-tail muffler. The level of heat transferred to the rider with that layout is only a fraction of what he might experience if the very hottest part of a 170-horsepower, inlineFour’s exhaust system, including the exhaust ports themselves, was under his butt.

As I explained in my reply to Mr. Miller, such a switch would be worthwhile if it netted some benefit in performance. Given all the factors involved, it would seem not to do so.

William Caughey Azusa, California

A As you may have read in our MasterBike comparison last month, we also encountered the same throttle-response problem with our R1 test bike. When we reported the matter to Yamaha, company representatives acknowledged that an unspecified number of 2007 Rls do indeed have such a problem, and that the company is taking steps to correct it. By the time you read this, Yamaha will have sent a Tech Exchange Service Bulletin to all of its Tech Field Staff, instructing them to diagnose any such reported throttle-response problems with the 2007 R1. As of this writing, Yamaha was not certain exactly how each problem bike would be dealt with; but since the problem seems to be related to the Rl’s computer-controlled fly-by-wire throttle system, the cure is likely to involve either reprogramming of the Engine Control Unit or maybe even installation of a replacement ECU. If your R1 ’s response problem has not yet been dealt with, you need to get the bike to your dealer ASAR □

Got a mechanical or technical problem with your beloved ride? Can’t seem to find workable solutions in your area? Or are you eager to learn about a certain aspect of motorcycle design and technology? Maybe we can help. If you think we can, either: 1) Mail a written inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/6310651; 3) e-mail it to CW1Dean@aol.com; or 4) log onto www.cycleworld.com, click on the “Contact Us” button, select “CW Service” and enter your question. Don’t write a 10page essay, but if you’re looking for help in solving a problem, do include enough information to permit a reasonable diagnosis. And please understand that due to the enormous volume of inquiries we receive, we cannot guarantee a reply to every question.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontAnatomy of A Black Eye

September 2007 By David Edwards -

Leanings

LeaningsA Trip To the New Barber

September 2007 By Peter Egan -

TDC

TDCTechnology Duel

September 2007 By Kevin Cameron -

Departments

DepartmentsHotshots

September 2007 -

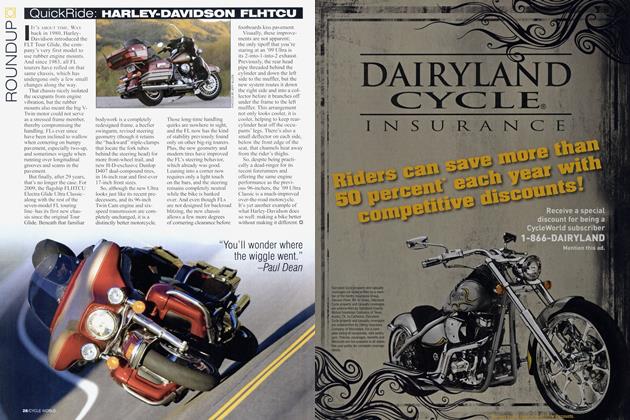

Roundup

RoundupSmaller, Lighter, Faster

September 2007 By Kevin Cameron -

Roundup

Roundup2008 Street Trip

September 2007 By Blake Conner