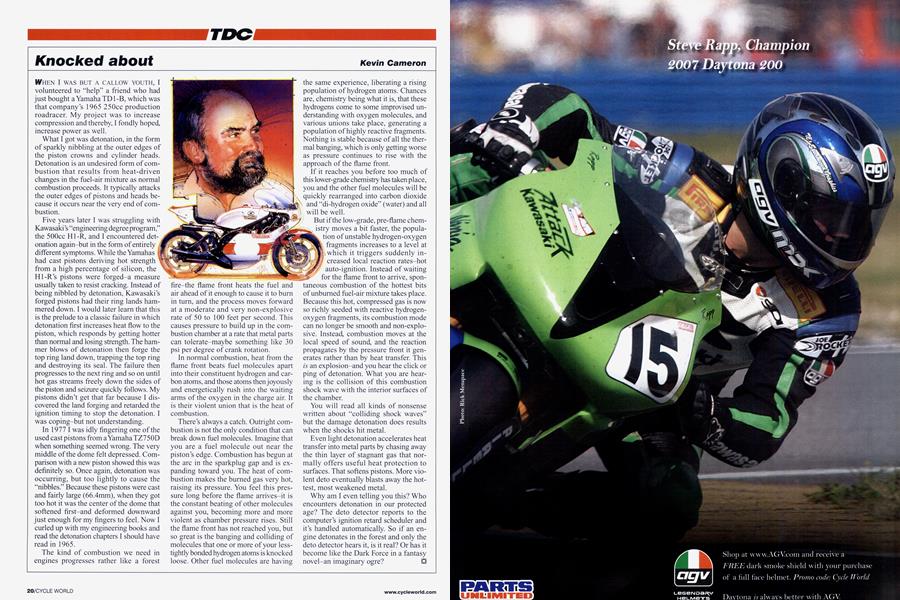

Knocked about

TDC

Kevin Cameron

WHEN I WAS BUT A CALLOW YOUTH, I volunteered to “help” a friend who had just bought a Yamaha TD1-B, which was that company’s 1965 250cc production roadracer. My project was to increase compression and thereby, I fondly hoped, increase power as well.

What I got was detonation, in the form of sparkly nibbling at the outer edges of the piston crowns and cylinder heads. Detonation is an undesired form of combustion that results from heat-driven changes in the fuel-air mixture as normal combustion proceeds. It typically attacks the outer edges of pistons and heads because it occurs near the very end of combustion.

Five years later I was struggling with Kawasaki’s “engineering degree program,” the 500cc Hl-R, and I encountered detonation again-but in the form of entirely , different symptoms. While the Yamahas | had cast pistons deriving hot strength \ from a high percentage of silicon, the FIl-R’s pistons were forged-a measure usually taken to resist cracking. Instead of being nibbled by detonation, Kawasaki’s forged pistons had their ring lands hammered down. I would later learn that this is the prelude to a classic failure in which detonation first increases heat flow to the piston, which responds by getting hotter than normal and losing strength. The hammer blows of detonation then forge the top ring land down, trapping the top ring and destroying its seal. The failure then progresses to the next ring and so on until hot gas streams freely down the sides of the piston and seizure quickly follows. My pistons didn’t get that far because I discovered the land forging and retarded the ignition timing to stop the detonation. I was coping-but not understanding.

In 1977 I was idly fingering one of the used cast pistons from a Yamaha TZ750D when something seemed wrong. The very middle of the dome felt depressed. Comparison with a new piston showed this was definitely so. Once again, detonation was occurring, but too lightly to cause the “nibbles.” Because these pistons were cast and fairly large (66.4mm), when they got too hot it was the center of the dome that softened first-and deformed downward just enough for my fingers to feel. Now I curled up with my engineering books and read the detonation chapters I should have read in 1965.

The kind of combustion we need in engines progresses rather like a forest

fire-the flame front heats the fuel and air ahead of it enough to cause it to burn in turn, and the process moves forward at a moderate and very non-explosive rate of 50 to 100 feet per second. This causes pressure to build up in the combustion chamber at a rate that metal parts can tolerate-maybe something like 30 psi per degree of crank rotation.

In normal combustion, heat from the flame front beats fuel molecules apart into their constituent hydrogen and carbon atoms, and those atoms then joyously and energetically rush into the waiting arms of the oxygen in the charge air. It is their violent union that is the heat of combustion.

There’s always a catch. Outright combustion is not the only condition that can break down fuel molecules. Imagine that you are a fuel molecule out near the piston’s edge. Combustion has begun at the arc in the sparkplug gap and is expanding toward you. The heat of combustion makes the burned gas very hot, raising its pressure. You feel this pressure long before the flame arrives-it is the constant beating of other molecules against you, becoming more and more violent as chamber pressure rises. Still the flame front has not reached you, but so great is the banging and colliding of molecules that one or more of your lesstightly bonded hydrogen atoms is knocked loose. Other fuel molecules are having

the same experience, liberating a rising population of hydrogen atoms. Chances are, chemistry being what it is, that these hydrogens come to some improvised understanding with oxygen molecules, and various unions take place, generating a population of highly reactive fragments. Nothing is stable because of all the thermal banging, which is only getting worse as pressure continues to rise with the approach of the flame front.

If it reaches you before too much of this lower-grade chemistry has taken place, you and the other fuel molecules will be quickly rearranged into carbon dioxide * and “di-hydrogen oxide” (water) and all will be well.

But if the low-grade, pre-flame chemistry moves a bit faster, the population of unstable hydrogen-oxygen fragments increases to a level at ; which it triggers suddenly increased local reaction rates-hot auto-ignition. Instead of waiting gp" for the flame front to arrive, spontaneous combustion of the hottest bits of unbumed fuel-air mixture takes place. Because this hot, compressed gas is now so richly seeded with reactive hydrogenoxygen fragments, its combustion mode can no longer be smooth and non-explosive. Instead, combustion moves at the local speed of sound, and the reaction propagates by the pressure front it generates rather than by heat transfer. This is an explosion-and you hear the click or ping of detonation. What you are hearing is the collision of this combustion shock wave with the interior surfaces of the chamber.

You will read all kinds of nonsense written about “colliding shock waves” but the damage detonation does results when the shocks hit metal.

Even light detonation accelerates heat transfer into metal parts by chasing away the thin layer of stagnant gas that normally offers useful heat protection to surfaces. That softens pistons. More violent deto eventually blasts away the hottest, most weakened metal.

Why am I even telling you this? Who encounters detonation in our protected age? The deto detector reports to the computer’s ignition retard scheduler and it’s handled automatically. So if an engine detonates in the forest and only the deto detector hears it, is it real? Or has it become like the Dark Force in a fantasy novel-an imaginary ogre? □