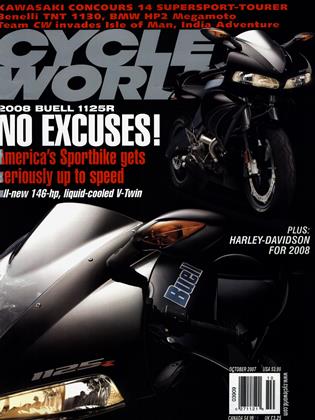

HEART TRANSPLANT

NEW BIKES 2008

Cutting into Buell's all-new 1125R

KEVIN CAMERON

ERIK BUELL IN THE 1970s WAS ONE OF AMERICA'S YOUNG MEN who had to race motorcycles. Soon, racing other people's designs just rubbed his fur backward. He wanted to be responsible for everything from the design concept forward. It has taken him years—2007 marks Buell Motor Company's 25th—to achieve this, but at last he is building a sportbike with a sportbike engine, the new-for-2008 Buell 1125R.

A 72-degree Rotax "Helicon" V-Twin, designed to specific Buell requirements, powers this new bike. The project is at least three years old and began with

the search for an engine-maker. In meetings, Buell would ask each company about its design process. As you’d expect, each was super-confident-one was described as giving the Vulcan salute while intoning, “We are very excellent!”

Then Buell went to Rotax, in Austria.

Their engineers said,

“We try to improve our design process but we sometimes make mistakes.

Then we fix them.”

Refreshing! Buell felt these were his kind

of engineers-people his team could work with. He explained that he wanted a Twin, that his customers were accustomed to Twins and that a Twin’s good torque characteristics were what he desired.

What Vee angle? Even before they had signed any kind of agreement, this was decided in the most freewheeling of meetings.

The Rotax men said, “We don’t want to repeat the errors of the Aprilia engine-60-degrees is too little. It crowds big-bore pistons near BDC. And the smaller the Vee angle, the bigger primary balancers you need.” (At 90 degrees, no primary balance shafts are needed; at 0 degrees, the engine shakes like a Single.)

But 90 degrees is too much-at least to keep the resulting long engine from being difficult to package in a motorcycle; you must make serious compromises. How about 80 degrees, tipped back to get the front head off the tire? No, because then the exhaust port of the rear cylinder becomes ugly, talking out of the side of its mouth to avoid nearby essentials.

Okay, 72 degrees? Only needs modest balancers, and with Buell’s idea for radiator placement, it would package close enough to the front wheel to allow the desired 54/46-percent front/rear weight bias. There

are bikes with less weight on the front but making them stable requires slower steering geometry than Buell-and his customers-likes.

One more thing! Buell wanted the rocking-couple balanced, as well. That is the slight back-and-forth twisting caused by the two connecting-rods being side-by-side on the single crankpin. Rod separation is small, but the forces are many tons. Multiplied times the length of the handlebar, this puts a tingle in riders’ hands. This was to be a bike to ride all day.

ith vibration quelled close to the source, the engine could be bolted rigidly to the chassis, contributing stiffness. Because this engine was not a recycled design, the location of engine mounts was open. The object of the exercise: Choose mounting points that would avoid undesirable chassis-oscillation frequencies. One MotoGP team completed its work of this kind one winter, only to find that tires supplied at early-season tests oscillated in step with important chassis modes. These problems have always existed but now there are tools for their prediction and analysis.

Buell has also seen the compromises imposed by too-short swingarms. A longer arm required oblique-stacked transmission shafts (six speeds, no less!) and pivoting the swingarm

directly on the back of the gearbox. Done.

And what is Buell’s cooling idea? On most motorcycles, it’s uncertain which way the air is going through the radiator, because it’s located in the front wheel’s turbulence, pushed against the front of the engine. What he wanted was a purer flow situation, with free-stream air entering the rad and heated air exiting to a low-pressure area-just as it does in a P-51 ofWWII. Therefore there is a radiator on either side of the bike, well forward. Ducts with internal splitters direct air inward through the hot cores, then down the center of the bike to exit into the low-pressure region under the seat.

What if the bike falls over? The radiator covers are separate parts-not a whole fairing-and the rads are mounted on leaf springs. Therefore tip-over damage is limited and not expensive.

Side radiators not only improve cooling, they also allow the engine to mount farther forward. This, in turn, allows the short, quick-turning wheelbase of 54.5-inches-with a swingarm of modern length. The longer swingarm, entirely cast in aluminum, is said to be 57 percent stiffer than previous Buell designs and 1 pound lighter. Put the metal where the stress is.

Meanwhile, a chassis took shape. As with other Buells, this one’s frame carries the fuel-5.6 gallons of it, thanks to

BUELL1125R

substantial beams and a much larger “wet” rear cross-member. This all-aluminum twin-beam chassis is now made in the USA. Here’s how: When the previous offshore supplier was unfamiliar with a new material or process, Buell engineers educated them. Hand-holding increased to more than a dull roar. With all this trouble, why not educate a nearby U.S. maker and forget the plane tickets? The big hurdle-fuel in the frame-had already been leaped. So now the frames are assembled by people with names like Bob and Carol and Pete, and all is well. The frame combines formed sheet and cast elements, and is said to be only a pound heavier than some much-admired MotoGP items.

Buell engineers praise the flexibility of engine partner Rotax. At one point in durability testing, a piston problem appeared. The test protocol was severe, but there was no hiding behind U.S. speed limits. Fix it. Although pistons are normally the engine-builder’s province, Buell engineers pride themselves on their in-house analytical department. They modeled the piston and looked at predicted stresses, but nothing like the actual failure appeared. More analysis. Nothing. Then, looking for less obvious sources of stress, they refined the conditions slightly and there it was, a red hotspot! Altered pistons easily passed the test.

Bore and stroke is 103 x 67.5mm, a ratio of just over 1.5:1.

That has been the workable compromise-found in most sportbikes-that balances the challenge of burning a thin, bigbore chamber quickly against the lowered piston speed and friction of a short stroke. With these dimensions, the engine is redlined at 10,500 rpm and makes a claimed 146 crank horsepower at 9800 rpm. Peak torque of 82 foot-pounds comes at 8000 revs. The numbers are comfortable and have room for growth.

Each in countless head has experiments: the number of four. valves In each proven head, optimum intake and exhaust cams are geared together and only one is driven by silent chain from the crank. Not driving both cams by chain permits them to be closer together, allowing a narrow 18-degree included valve angle and more-compact combustion chamber. Valve actuation is by finger follower, clearance adjustment by shim. No spring compression is required for clearance adjustment, as the fingers can be released and slid laterally to permit shim changes. Finger followers, because of their lightness and adaptability to increased lifts, have displaced inverted bucket followers in Formula One.

Buell’s products are hugely ambitious. Here are two buildings in a modest industrial park manufacturing motorcycles of remarkable innovation, and there are only 160 employees.

How can the limited number of engineers at Buell accomplish all that must be done?

An incomplete, first-level answer is “analysis,” a buzzword in technical industries. Finite Element Analysis accurately predicts (well, mostly-see piston problem above!) stresses in parts, reducing the number of very expensive and time-consuming test hours that must be run on rig, dyno and track. Mode analysis uses similar information to predict vibratory modes in structures and surfaces. Rapidly maturing CFD (Computational Fluid Dynamics) is now able to answer internal and external flow problems that formerly yielded only to wind-tunnel and engine tests.

But where is the economy in moving engineers from test to analysis? All forms of human activity can generate vast data. The objective is to extract its meaning for the task at hand. This company has developed a central informationmanagement system that makes all information (including warranty reports) on all parts and projects available to all personnel on the network, continuously updated. In many companies, each department generates and manages its own information, generating a “Tower of Babel” of mutually unintelligible systems, each defended in bitter turf wars.

Erik Buell, knowing that test and analysis departments are normally at one another’s throats, decided to put both under the always slightly smiling Abe Askenazi, his job to draw together simulation and reality, to make good designs and simultaneously refine the tools that produce them.

It is a law of organizations that high-ranking persons make the Kool-Aid and low-rankers must drink it-or face “employment discontinuity.” Talented but low-ranking people leave rather than knuckle under, so Yes Persons remain. To prevent this, Buell’s engineering system calls upon every engineer to rate parts or solutions under a green/yellow/red system. Green signifies agreement, but any party to the process can raise objections that must be dealt with. For engineering, this resembles a Japanese production line, on which every worker has a STOP button that must be pushed if a possible defect is seen. In this way, no engineer at Buell can settle into a narrow specialization-as a grizzled consultant once put it to me, “Spending your whole career designing some bolt.” Instead, at weekly meetings, engineers with yellow or red concerns can explain their views and receive fresh information.

As Buell says, “Not everyone wants to work this way,” but those who remain thrive in an informationand idea-rich dialogue that covers every part of every model. This combination of easy and central information access with the green/ yellow/red status system focuses many good minds-most of them fresh from other engineering work-on any problem. Solutions come quickly and efficiently, and engineers start to think of the motorcycle as a whole.

This is a serious concern in MotoGP development, and surely in the industry that underlies it. The norm is for each area of performance-suspension, engine mapping, data interpretation-to have its own specialist. Because specialists know more about what they are doing than can anyone in charge overall, the manager tends to defer to the specialist. Each specialization goes its own way, according to its own logic, with no one performing the central task of system integration.

Testing ated the remains 1125R very prototype important. and rear As top suspension riders evaluwas progressively refined, their concerns focused on the front. They found vagueness and lack of feel. Tests with the usual alternative forks offered no solution. Now the Showa engineers revealed that they had in process a new motocrossderived 47mm-tube fork, and that an advanced large damping cartridge, too big for current production forks, could be

used in it. This 47mm inverted fork resolved the 1125R test concerns and became standard fitment.

The Buell analysis department is a sunny, open work area, with the expected computers and screens. Here I saw what had previously been described: a program that generates optimal parts shapes. Given numerous boundary conditions, it gets to work eliminating elements of volume that carry little stress, keeping those that carry more, cycling through its algorithm to a refined answer. On the screen, I saw the rear wheel’s belt sprocket shape emerge from this process. All parts at Buell now pass through analysis.

Flow muffler, and wave but what analysis can defend define our the ears interior from shape the tinny of a slap of its vibrating shell, as pressure waves strike it from within? The answer is to give it compound curvatures whose self-stiffening effect pushes vibratory frequencies up out of our hearing. Now we hear the pure rumble of the engine. Years ago, when Buell produced its first “Corvair muffler,” we all thought it was ugly, making the bike look like an airplane carrying a torpedo.

“But performance is good,” Buell said, noting that small mufflers are either too loud or too restrictive. Since then, one manufacturer after another, desperate to find adequate muffler volume, has turned to his solution. Today the “RFD mailbox” style of high, side-mounted muffler begins to look...well, clumsy, even dated. And it violates the important principle of mass centralization. Plus, with the fuel in the frame, the entire volume above the engine is available as airbox. Remember that both Aprilia and Ducati undertook extensive chassis redesigns in search of more airbox volume.

Buell refers to its “Trilogy of Technology.” These are: Mass centralization. Achieved by locating major masses-engine, chassis, fuel-at the center, to increase maneuverability. The farther a part is from center, the more important it becomes that it be light-like the 1125's magnesium instrument and fairing bracket up front.

Low unsprung weight. The lighter the wheels, brakes

and tires become, the more accurately they can track road irregularities. Spending more time on the pavement, the tires generate more grip.

Chassis rigidity. This doesn’t mean the more rigid, the better. It means choosing the degree and orientation of chassis rigidities to achieve specific goals.

Up front, the single 375mm brake disc attaches directly to bosses on the rim. Wheel spokes, no longer having to transmit 600 foot-pounds of brake torque, can be lighter. Buell says the single disc and special Nissin eight-piston caliper save 6 pounds of unsprung weight compared to a conventional dual-disc brake. The unusual hollow caliper was designed in Buell’s analysis shop, with its metal located to give maximum resistance to clamp loads. The result is powerful braking with a firm lever.

At the rear, a 1.06-pound Goodyear Hibrex toothbelt (reinforced with Flexten Plus aramid fiber) saves 75 percent of the 4.5to 5-pound weight of a steel O-ring chain. More weight is saved by eliminating the normal rear caliper bracket (necessary only if the rear axle is to move in adjusting chain tension) and just bolting the caliper to the swingarm. The cush drive is moved out of the wheel and into the countershaft sprocket. Naturally, there are no chain-adjust yokes and adjuster bolts-the rear axle slides neatly through simple holes in the swingarm ends.

In sum, the story here is not just evolution of yet another state-of-the-art high-performance sportbike. It is also a story of how a small group of engineers devised ways to multiply their effectiveness. They found means to summon more ideas from a small group by taking all parties seriously. And they cut a chronic source of organizational friction by placing test and analysis in a single department.

Buell was long lumped into the “boutique brands” because they were limited to domestic engines. No doubt, they learned a great deal from their air-cooled designs and by no means regret the work that has gone into making them as good as they are. But now that the 1125R has a full-on sportbike powerplant, who knows what they might attempt next?E3