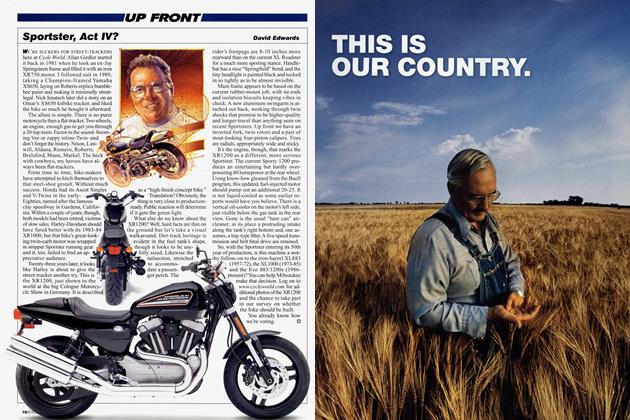

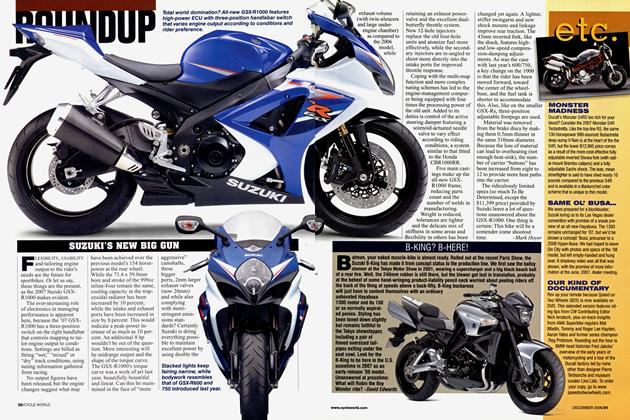

SLICK SIX

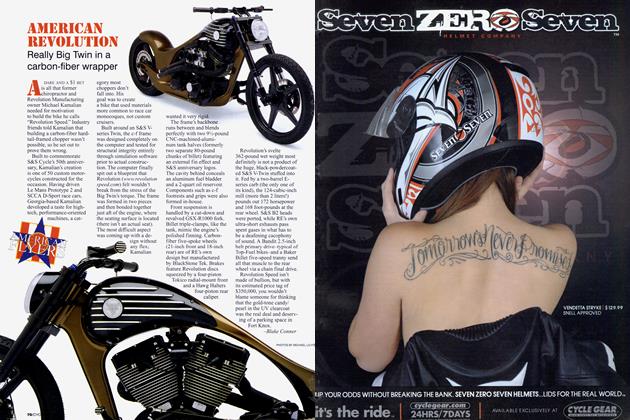

American FLYERS

Building a crown for Honda's jewel

SOME ENGINES JUST INCITE passion. They may not be the most practical, the most durable, the most powerful or even the finest design, but there is a character and personality to some powerplants that cannot be suppressed.

Count the Honda CBX sixcylinder among the mechanical works of art that seduce even the most rational among us.

And count Tryg Westby among its greatest fans. Mr. Westby might also have built the perfect platform in which to display the silky-smooth dohc 1047cc mill.

‘T always loved that engine and thought it needed to be showcased in something neat,” says Westby. “It has the air of the old GP motor from the Sixties, and it’s just as close as I could get to something like that.” Westby, 55, bought his first CBX new in 1979 and also had ’80, ’81 and ’82 models in the collection all at once. He sold off the later ones but still has his first and always wanted to do the engine justice.

Not wanting to butcher his original bike, he needed a powerplant, and the perfect opportunity arose. It just took a while to get it in his hands.

“I knew of this ’81 CBX that the original owner had lent to his cousin years ago and the guy crashed it,” relates Westby. “It was an ’81 model, and the engine only had 348 miles on it. I begged him for it for years and I finally got it.”

Westby is a pro bike builder who sold his Tulsa, Oklahoma, shop-Kinetic Playground in 2004 after years of successful custom-bike building, including plenty of Harley-type machines. But, as a successful national-level ex-roadracer (qualified row two behind Freddie Spencer at Daytona in ’84), he’d always wanted to show what could be done on the sporting side, so the CBX project was born.

“I sold my shop to a longtime customer and friend and opened up next door-I call it the R&D department, for Racing and Dicking off!” says Westby with a chuckle.

It doesn’t get much more sporting than a 7020 aluminumalloy chassis and swingarm from Spondon in England. Ordered direct, it will run you at least £3600, or about $6600. Plus shipping, of course. At least it will be reasonably light for the sake of the air-freight bill. All this assumes that they will make one for you.

“I was lucky as hell Spondon built it at all,” Westby says. “I was after them for about six months. I guess finally another fellow in South Africa called and wanted one, so they went ahead and built them.”

Naturally the single-sided swingarm wears a Honda RC45 hub and rear wheel. The front wheel is a Marchesini meant to fit a Ducati 996 and uses a rim-mounted Braking disc and caliper.

“I ordered a five-spoke Honda-type front wheel, but Marchesini had stopped making the kits and this is what they sent me. There weren’t any others left so I had to use it.”

In addition to the frame and rear arm, Spondon also provided the hand-ham mered aluminum fuel tank, which Westby says looks a lot like a CBR900RR unit, only wider. As the owner of a large Honda dealership in Tulsa for 10 years, Westby knows the bikes of Big Red.

For additional photography of American Flyers #21, go to www.cycleworld.com

"All that Spondon stuff is just so light-you can pick it up with one hand," he says. "The engine, though, that is a chunk! It took two of us to put it in the frame." Westby says the engine is bone stock. "I just wanted to get it in there and make it work," he says. "And with so few miles on it, I thought it would be a shame to tear it down. The guy did every thing right storing it-drained the carbs, shot some oil in the cylinders-it is just so quiet, you can barely hear it run fling at idle."

Bodywork is a mishmash of stuff, with a battered Sharkskinz tailsection from his son's SV650 racebike repurposed for use here ("I tried RC3O and RC45 pieces but they just didn't look right."), a Ducati 996 front fender and a supermoto-inspired mini fairing ordered from Europe.

"I made solid mounts for the fairing and a lot of the other stuff on the bike," says Westby. "I learned quite a bit about aluminum fabrica tion. I used to just run over to the saw and cut, but now I have learned that hand-fil ing is the way. I know how those old-time craftsmen did it-they took their time."

Paint features a black base with gold stripes and silver pinstripes. "It's just like the old CBX scheme; I just cop ied it," he says.

No CBX custom would be complete without the pipe organ that is the exhaust system. While the headers were ordered from Lazer in Holland, the rest of the sys tem comes as the result of local expertise.

"My good friend Greg Bush can machine or make just about anything in his garage," Westby says. "He fabricated from the exhaust collector up to the Micron silencer I used in racing. It was dinged so we just cut that part off and made it shorter! The guy is amazing. He also did the triple-clamps.

We got really thick aluminum pieces and sunk the digital gauges down in it." Aside from hiding the gauges and fab ricating a countershaft pickup for the aftermarket speedo, the rest of the electrics were pretty straightforward: "That CBX wiring harness was just a joy," he says. "I was doing my own harnesses on our custom Harleys and it was just plug and play with the Honda harness."

A racer's background meant nothing but Ohlins would do front and rear, and while Westby says he definitely fears crashing the bike, it was built to ride.

"I'd hate to have to build it all again," he says earnestly. "I scratched my head bald for two years trying to figure it all out."

Judging by the results, we all should open our own R&D departments.

Mark Hoyer

View Full Issue

View Full Issue