TDC

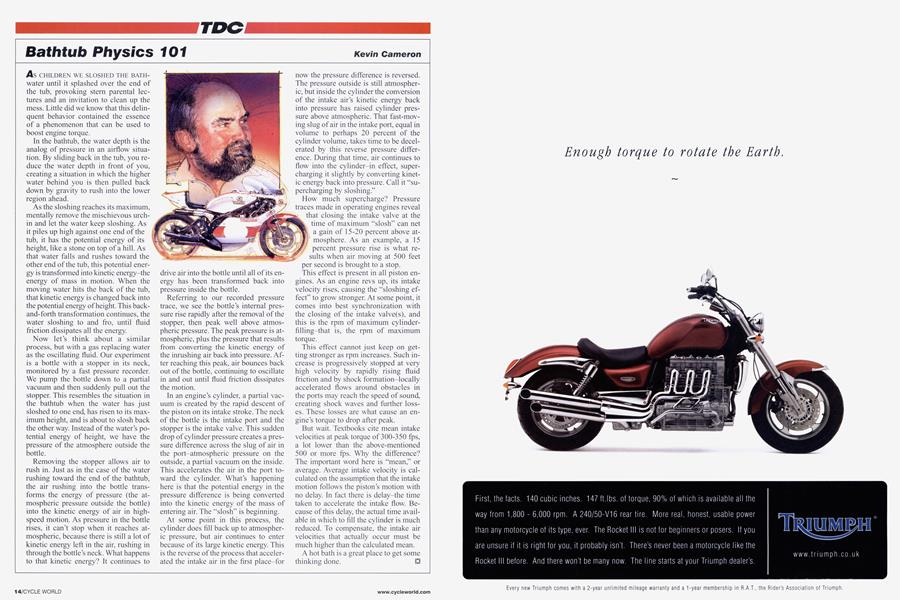

Bathtub Physics 101

Kevin Cameron

AS CHILDREN WE SLOSHED THE BATH-water until it splashed over the end of the tub, provoking stern parental lectures and an invitation to clean up the mess. Little did we know that this delinquent behavior contained the essence of a phenomenon that can be used to boost engine torque.

In the bathtub, the water depth is the analog of pressure in an airflow situation. By sliding back in the tub, you reduce the water depth in front of you, creating a situation in which the higher water behind you is then pulled back down by gravity to rush into the lower region ahead.

As the sloshing reaches its maximum, mentally remove the mischievous urchin and let the water keep sloshing. As it piles up high against one end of the tub, it has the potential energy of its height, like a stone on top of a hill. As that water falls and rushes toward the other end of the tub, this potential energy is transformed into kinetic energy-the energy of mass in motion. When the moving water hits the back of the tub, that kinetic energy is changed back into the potential energy of height. This backand-forth transformation continues, the water sloshing to and fro, until fluid friction dissipates all the energy.

Now let’s think about a similar process, but with a gas replacing water as the oscillating fluid. Our experiment is a bottle with a stopper in its neck, monitored by a fast pressure recorder. We pump the bottle down to a partial vacuum and then suddenly pull out the stopper. This resembles the situation in the bathtub when the water has just sloshed to one end, has risen to its maximum height, and is about to slosh back the other way. Instead of the water’s potential energy of height, we have the pressure of the atmosphere outside the bottle.

Removing the stopper allows air to rush in. Just as in the case of the water rushing toward the end of the bathtub, the air rushing into the bottle transforms the energy of pressure (the atmospheric pressure outside the bottle) into the kinetic energy of air in highspeed motion. As pressure in the bottle rises, it can’t stop when it reaches atmospheric, because there is still a lot of kinetic energy left in the air, rushing in through the bottle’s neck. What happens to that kinetic energy? It continues to drive air into the bottle until all of its energy has been transformed back into pressure inside the bottle.

Referring to our recorded pressure trace, we see the bottle’s internal pressure rise rapidly after the removal of the stopper, then peak well above atmospheric pressure. The peak pressure is atmospheric, plus the pressure that results from converting the kinetic energy of the inrushing air back into pressure. After reaching this peak, air bounces back out of the bottle, continuing to oscillate in and out until fluid friction dissipates the motion.

In an engine’s cylinder, a partial vacuum is created by the rapid descent of the piston on its intake stroke. The neck of the bottle is the intake port and the stopper is the intake valve. This sudden drop of cylinder pressure creates a pressure difference across the slug of air in the port-atmospheric pressure on the outside, a partial vacuum on the inside. This accelerates the air in the port toward the cylinder. What’s happening here is that the potential energy in the pressure difference is being converted into the kinetic energy of the mass of entering air. The “slosh” is beginning.

At some point in this process, the cylinder does fill back up to atmospheric pressure, but air continues to enter because of its large kinetic energy. This is the reverse of the process that accelerated the intake air in the first place-for now the pressure difference is reversed. The pressure outside is still atmospheric, but inside the cylinder the conversion of the intake air’s kinetic energy back into pressure has raised cylinder pressure above atmospheric. That fast-moving slug of air in the intake port, equal in volume to perhaps 20 percent of the cylinder volume, takes time to be decelerated by this reverse pressure difference. During that time, air continues to flow into the cylinder-in effect, supercharging it slightly by converting kinetic energy back into pressure. Call it “supercharging by sloshing.”

How much supercharge? Pressure traces made in operating engines reveal that closing the intake valve at the time of maximum “slosh” can net a gain of 15-20 percent above atmosphere. As an example, a 15 percent pressure rise is what results when air moving at 500 feet per second is brought to a stop.

This effect is present in all piston engines. As an engine revs up, its intake velocity rises, causing the “sloshing effect” to grow stronger. At some point, it comes into best synchronization with the closing of the intake valve(s), and this is the rpm of maximum cylinderfilling-that is, the rpm of maximum torque.

This effect cannot just keep on getting stronger as rpm increases. Such increase is progressively stopped at very high velocity by rapidly rising fluid friction and by shock formation-locally accelerated flows around obstacles in the ports may reach the speed of sound, creating shock waves and further losses. These losses are what cause an engine’s torque to drop after peak.

But wait. Textbooks cite mean intake velocities at peak torque of 300-350 fps, a lot lower than the above-mentioned 500 or more fps. Why the difference? The important word here is “mean,” or average. Average intake velocity is calculated on the assumption that the intake motion follows the piston’s motion with no delay. In fact there is delay-the time taken to accelerate the intake flow. Because of this delay, the actual time available in which to fill the cylinder is much reduced. To compensate, the intake air velocities that actually occur must be much higher than the calculated mean.

A hot bath is a great place to get some thinking done.