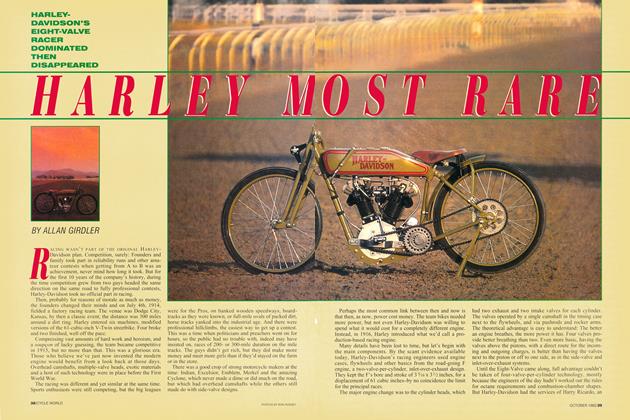

Ti Tech

When it comes to valves, light (at last) makes right

WHY DOES A MANUFACTURER PUT EXPENSIVE TITANIUM valves in place of much cheaper steel valves of proven durability? The answer is to raise the rpm redline and continue the search for free power through detailed friction reduction.

But just putting titanium in place of steel accomplishes little. Super-tuner Rob Muzzy tested titanium valves in his Kawasaki Superbike race engines years ago and found nothing-no power increase from the higher revs thereby made possible, and no friction reduction. Why not?

Friction rises roughly as the square of rpm-fast enough to eat any power gain realized from higher revs. This is because the forces that accelerate pistons and rods increase as the square of speed and must be carried by crank main and rod bearings.

To avoid this ruinous “friction tax” and actually gain power from higher revs, the whole engine must go on a diet, as Suzuki has done with this new GSX-R600-lighter pistons, lighter rods, smaller main bearings and titanium valves. In this way, the higher revs do not eat the extra power that comes from performing the power-producing cycle more times per minute. This detailed friction fighting is what has brought production motorcycle engines three-quarters of the way to the almost 20,000 rpm of current Formula One engines. Good going.

Then why titanium valves? As valves are accelerated harder by higher revs, a point is reached beyond which the valve springs lack sufficient pressure to accelerate the valves and tappets hard enough to keep them in contact with cam profiles. This is valve float. Shall we make the springs stiffer? We could, but then idling along the boulevard at 5000 revs, the camshafts must support that extra force at every lobe and every journal. This increases friction loss.

Therefore, just as pistons and rods were made lighter, so shall the valves be-by about the weight difference between steel and titanium: 40 percent. With this large mass reduction, we can make springs slightly softer and still keep valves obediently following cam profiles out to our new, higher redline.

Titanium became available in the 1950s, when Jack Williams of AJS made the first connecting rods of it.

Why, then, with its wonderful weight advantage, did it take 50 years to be adopted as production valve material?

The answer is that valve-operating temperatures in motorcycle engines had to fall hundreds of degrees for titanium to survive. In the 1950s and ’60s, the exhaust valves of high-powered air-cooled motorcycle engines had to be made of exotic turbine alloys to live. When four valves replaced two, valves became smaller, shortening the heat path and cutting the operating temperature of exhaust valves. Then, in the 1980s, liquid-cooling was widely adopted, further dropping valve temperatures. Meanwhile, increased production had made titanium cheaper. Plated or vapor-deposited coatings prevented the stem galling or seizure that “sticky” bare titanium invites. The result of all these changes and new technologies is that titanium valves have at last earned a place in production streetbike engines. -Kevin Cameron

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontMending History

May 2004 By David Edwards -

Leanings

LeaningsThe Forgotten Passenger

May 2004 By Peter Egan -

TDC

TDCInvisible Seal

May 2004 By Kevin Cameron -

Departments

DepartmentsHotshots

May 2004 -

Roundup

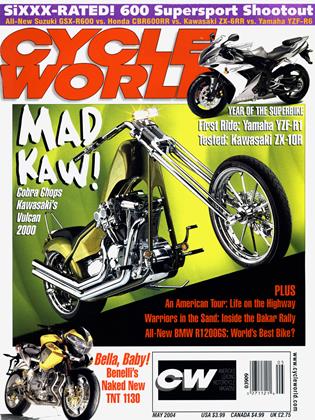

RoundupDy-No-Mite! Benelli Unveils Tnt Naked Bike

May 2004 By Bruno De Prato -

Roundup

RoundupVtx Show-Shocker

May 2004 By Mark Hoyer