Heavy duty

TDC

Kevin Cameron

MOTORCYCLE DURABILITY HAS TO INcrease constantly. As one dealer declared to me, “The stronger the manufacturers make the bikes, the harder people abuse them. Five years ago, the clutch on our liter-bike was good for one burnout and people complained when it wouldn’t survive 10. Now, they’ve made it strong enough for 10 and riders want 100.”

That’s life. Young men in the 16-25 age group require action. They build rockets, enter burnout contests, join the Marines, play guitars beneath Juliet’s balcony. This will not change, so motorcycles must.

This is the reason why sportbike engines are adopting forged pistons and nitrogen-hardened or shotpeened con-rods. As peak piston acceleration increases with rising rpm, the fatigue resistance of reciprocating parts has to increase-or failures will.

Other makers have adopted valve springs made of oval wire to get more stiffness out of a given spring weight. “Beehive” valve springs-those that taper toward the spring retainer-reduce the mass of spring that moves with the valve, and so increase the safe rpm of float-free operation. They also flummox the end-to-end compression waves that can quickly fatigue valve springs.

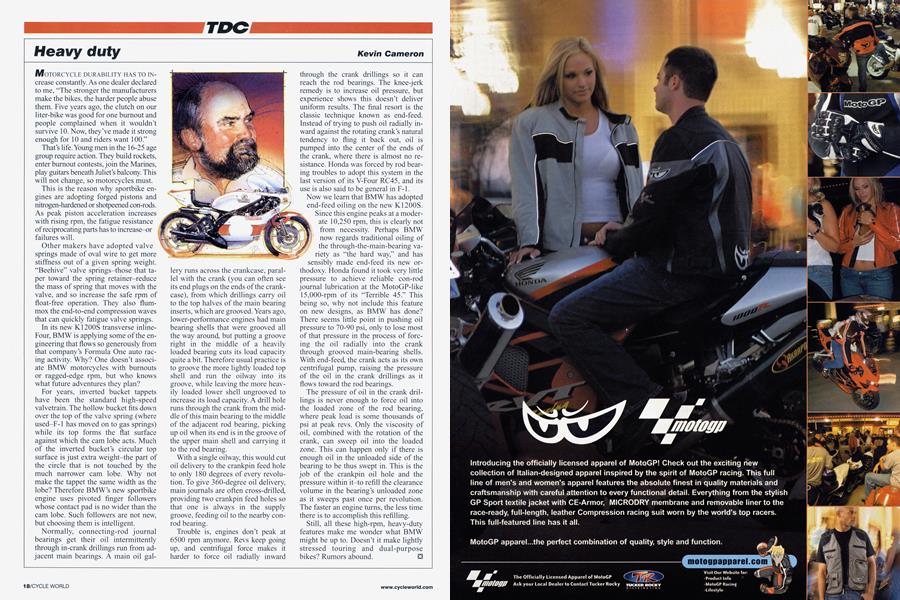

In its new K1200S transverse inlineFour, BMW is applying some of the engineering that flows so generously from that company’s Formula One auto racing activity. Why? One doesn’t associate BMW motorcycles with burnouts or ragged-edge rpm, but who knows what future adventures they plan?

For years, inverted bucket tappets have been the standard high-speed valvetrain. The hollow bucket fits down over the top of the valve spring (where used-F-1 has moved on to gas springs) while its top forms the flat surface against which the cam lobe acts. Much of the inverted bucket’s circular top surface is just extra weight-the part of the circle that is not touched by the much narrower cam lobe. Why not make the tappet the same width as the lobe? Therefore BMW’s new sportbike engine uses pivoted finger followers whose contact pad is no wider than the cam lobe. Such followers are not new, but choosing them is intelligent.

Normally, connecting-rod journal bearings get their oil intermittently through in-crank drillings run from adjacent main bearings. A main oil gallery runs across the crankcase, parallel with the crank (you can often see its end plugs on the ends of the crankcase), from which drillings carry oil to the top halves of the main bearing inserts, which are grooved. Years ago, lower-performance engines had main bearing shells that were grooved all the way around, but putting a groove right in the middle of a heavily loaded bearing cuts its load capacity quite a bit. Therefore usual practice is to groove the more lightly loaded top shell and run the oilway into its groove, while leaving the more heavily loaded lower shell ungrooved to increase its load capacity. A drill hole runs through the crank from the middle of this main bearing to the middle of the adjacent rod bearing, picking up oil when its end is in the groove of the upper main shell and carrying it to the rod bearing.

With a single oilway, this would cut oil delivery to the crankpin feed hole to only 180 degrees of every revolution. To give 360-degree oil delivery, main journals are often cross-drilled, providing two crankpin feed holes so that one is always in the supply groove, feeding oil to the nearby conrod bearing.

Trouble is, engines don’t peak at 6500 rpm anymore. Revs keep going up, and centrifugal force makes it harder to force oil radially inward through the crank drillings so it can reach the rod bearings. The knee-jerk remedy is to increase oil pressure, but experience shows this doesn't deliver uniform results. The final resort is the classic technique known as end-feed. Instead of trying to push oil radially in ward against the rotating crank's natural tendency to fling it back out, oil is pumped into the center of the ends of the crank, where there is almost no re sistance. Honda was forced by rod bear ing troubles to adopt this system in the last version of its V-Four RC45, and its use is also said to be general in F-i.

Now we learn that BMW has adopted end-feed oiling on the new K1200S. ) Since this engine peaks at a moder ate 10,250 rpm, this is clearly not from necessity. Perhaps BMW now regards traditional oiling of / the through-the-main-bearing Va riety as "the hard way," and has sensibly made end-feed its new or thodoxy. Honda found it took very little pressure to achieve reliable con-rod journal lubrication at the MotoGP-like 15,000-rpm of its "Terrible 45." This being so, why not include this feature on new designs, as BMW has done? There seems little point in pushing oil pressure to 70-90 psi, only to lose most of that pressure in the process of forc ing the oil radially into the crank through grooved main-bearing shells. With end-feed, the crank acts as its own centrifugal pump, raising the pressure of the oil in the crank drillings as it flows toward the rod bearings.

The pressure of oil in the crank dril lings is never enough to force oil into the loaded zone of the rod bearing, where peak load is some thousands of psi at peak revs. Only the viscosity of oil, combined with the rotation of the crank, can sweep oil into the loaded zone. This can happen only if there is enough oil in the unloaded side of the bearing to be thus swept in. This is the job of the crankpin oil hole and the pressure within it-to refill the clearance volume in the bearing's unloaded zone as it sweeps past once per revolution. The faster an engine turns, the less time there is to accomplish this refilling.

Still, all these high-rpm, heavy-duty features make me wonder what BMW might be up to. Doesn't it make lightly stressed touring and dual-purpose bikes? Rumors abound.

View Full Issue

View Full Issue