Bigger Big Bangs?

TDC

Kevin Cameron

BOOK MORE DYNO TIME! AS IF THEIR workloads weren’t intense enough already, MotoGP racing teams with traction problems or whose engines “hit” too hard in their powerbands are currently trying to find increased grip through altered firing orders.

Ducati, whose uprated 2004 engine produces more wheelspin than acceleration, is now experimenting with firing pairs of cylinders together-or nearly so-producing a low, droning exhaust note instead of the former “ripping cloth” sound. Ducati call this firing order “Twin Pulse,” because instead of four torque pulses per complete engine cycle there are two.

Suzuki has engines with both 180and 360-degree crankpin spacing. Yamaha, too, has a flatter exhaust note, suggesting it has abandoned the classic, 180degree-firing “flat” crankshaft.

The aim of all these changes is to deliver one broad torque pulse per crank revolution, rather than smaller pulses spaced 180 degrees apart. There are engineering problems of vibration and clutch/gearbox durability involved in delivering power in fewer but larger pulses.

Why should this increase grip? Many years ago dirt-track racers claimed that a 500cc Single accelerated quicker off corners than a Twin of the same power. This could be attributed to differences between two different kinds of powerbands, but when in 1992-93 Honda changed its NSR500 GP two-stroke to a narrow “Big Bang” firing angle, there was apparent benefit. But why should four cylinder firings added in pairs total more than if added separately?

Honda’s explanation for improved off-corner grip during leaned-over acceleration was that Big Bang firing order worked like anti-lock brakes in reverse. The idea was that the tire would momentarily grip as a large torque pulse was applied, and just as it began to slide that torque pulse would die away. The tire would then recover its grip, only to be hit with another large torque pulse-and so on.

Another way to think of this is to remember that when you slide a crated motorcycle across the shop floor, it takes more force to break the static friction of a crate that is sitting still than it does to keep it sliding once it begins to move. Static friction (a.k.a. “stiction”) is greater than sliding friction.

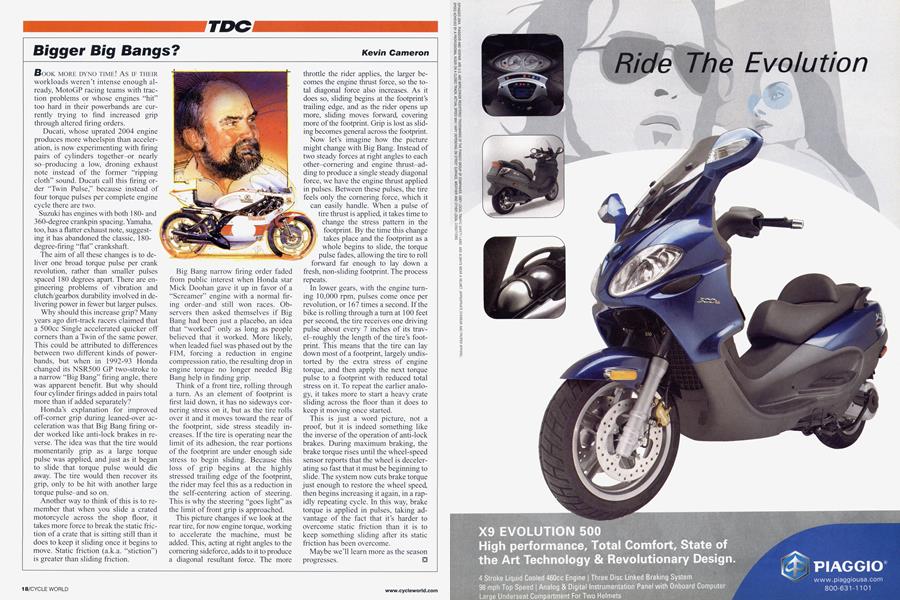

Big Bang narrow firing order faded from public interest when Honda star Mick Doohan gave it up in favor of a “Screamer” engine with a normal firing order-and still won races. Observers then asked themselves if Big Bang had been just a placebo, an idea that “worked” only as long as people believed that it worked. More likely, when leaded fuel was phased out by the FIM, forcing a reduction in engine compression ratio, the resulting drop in engine torque no longer needed Big Bang help in finding grip.

Think of a front tire, rolling through a turn. As an element of footprint is first laid down, it has no sideways cornering stress on it, but as the tire rolls over it and it moves toward the rear of the footprint, side stress steadily increases. If the tire is operating near the limit of its adhesion, the rear portions of the footprint are under enough side stress to begin sliding. Because this loss of grip begins at the highly stressed trailing edge of the footprint, the rider may feel this as a reduction in the self-centering action of steering. This is why the steering “goes light” as the limit of front grip is approached.

This picture changes if we look at the rear tire, for now engine torque, working to accelerate the machine, must be added. This, acting at right angles to the cornering sideforce, adds to it to produce a diagonal resultant force. The more throttle the rider applies, the larger becomes the engine thrust force, so the total diagonal force also increases. As it does so, sliding begins at the footprint’s trailing edge, and as the rider opens up more, sliding moves forward, covering more of the footprint. Grip is lost as sliding becomes general across the footprint.

Now let’s imagine how the picture might change with Big Bang. Instead of two steady forces at right angles to each other-cornering and engine thrust-adding to produce a single steady diagonal force, we have the engine thrust applied in pulses. Between these pulses, the tire feels only the cornering force, which it can easily handle. When a pulse of tire thrust is applied, it takes time to change the stress pattern in the footprint. By the time this change takes place and the footprint as a whole begins to slide, the torque pulse fades, allowing the tire to roll forward far enough to lay down a fresh, non-sliding footprint. The process repeats.

In lower gears, with the engine turning 10,000 rpm, pulses come once per revolution, or 167 times a second. If the bike is rolling through a turn at 100 feet per second, the tire receives one driving pulse about every 7 inches of its travel-roughly the length of the tire’s footprint. This means that the tire can lay down most of a footprint, largely undistorted by the extra stress of engine torque, and then apply the next torque pulse to a footprint with reduced total stress on it. To repeat the earlier analogy, it takes more to start a heavy crate sliding across the floor than it does to keep it moving once started.

This is just a word picture, not a proof, but it is indeed something like the inverse of the operation of anti-lock brakes. During maximum braking, the brake torque rises until the wheel-speed sensor reports that the wheel is decelerating so fast that it must be beginning to slide. The system now cuts brake torque just enough to restore the wheel speed, then begins increasing it again, in a rapidly repeating cycle. In this way, brake torque is applied in pulses, taking advantage of the fact that it’s harder to overcome static friction than it is to keep something sliding after its static friction has been overcome.

Maybe we’ll learn more as the season progresses.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontThe Accidental Sport-Tourist

November 2004 By David Edwards -

Leanings

LeaningsKtm Unplugged

November 2004 By Peter Egan -

Departments

DepartmentsHotshots

November 2004 -

Roundup

Roundup2005 Bmw K1200s: Too Fast For the Autobahn?

November 2004 By Brian Catterson -

Roundup

RoundupBmw Goes To Motogp

November 2004 By Bruno Deprato -

Roundup

RoundupEtc.

November 2004