Winged Devil

RACE WATCH

KEVIN CAMERON

One man's assault on the invisible

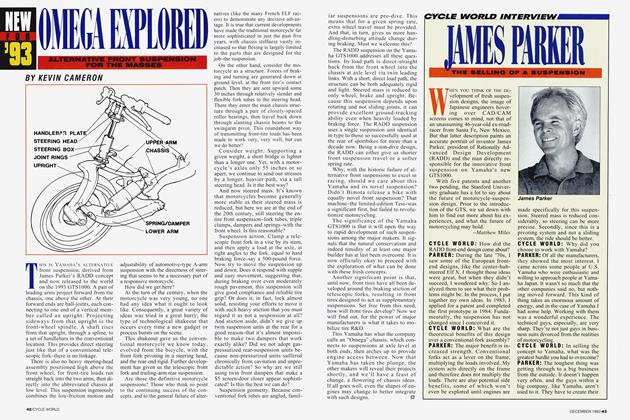

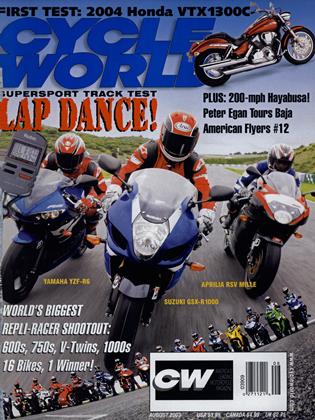

G0 YOUR All LNTION'! kVLRYl I IING A14( )t ;T Fl uS RlKE~ grabs the eye. but the wings are the anchor, the one thing that just won't let you go. They are meant to he an integral part ol' what has become one man's personal assault on the 200-mph harrier, a speed never broken in competition on U.S. roadracing tracks. Rad Greaves-the man behind the machine-aims to do it first with this monster Suzuki Hayabusa Formula Xtreme bike. This season will be his last chance, as the AMA has changed FX rules for '04 that will render his over-horsepowered beast illegal. Collaborating on the project are such heavies as Roush Industries (swoopy carbon-fiber shapes, windtunnel time) and Yoshimura (say no more). The idea is either to persuade the air molecules to stand aside or, if courtesy fails, to rudely shove past them with the 250 horsepower available from the heavily modified 1661 cc Giant Torquer Hayabusa engine.

Why break 200 mph on a closed circuit? Greaves is curious about high speeds, and he loves making Hayabusas into roadrace bikes (see “Super ’Busa,” CW November, 2000). During a race weekend, he walked the long, 3960-foot straightaway at Brainerd International Raceway in Minnesota, carrying a radar gun to measure speeds at various points, plotting the acceleration curves of AMA roadracers in different classes. The curves go up steeply at first, then level off. It fascinated him that the shape of the curves was the same whether the bikes were 250cc Grand Prix machines, production-based Supersport bikes or Superbikes. At any point on these curves, the slope is the acceleration -steeply upward is rapid acceleration, while a more gradual slope indicates redueed acceleration. This bothered Greaves because it looked like there was some kind of barrier that was stopping a 200-horsepower Superbike almost as fast as it was stopping a 90-bhp 250. What could that be?

Physics provides good answers here. Drag force increases as the square of the speed, but power is force times speed, so we have to multiply speed in a third time. This means that the horsepower required to overcome aerodynamic drag rises as the cube of speed. In other words, to double your speed, you need 2 x 2 x 2 = 8 times more power. Looked at by itself, the aerodynamic drag curve rises ever more steeply until it becomes essentially vertical-like a barrier. The faster you go, the more power is consumed by drag, leaving less and less with which to accelerate. This is why the acceleration curve rises so steeply at first (little drag = more left over for accelerating) and then flattens off (lots of drag leaves little for acceleration). This blunts the high-speed acceleration of even the most powerful bike-making just the kind of curve Greaves plotted at Brainerd.

Aha, but don't motorcycle drag coefficients constantly improve? What about all the claims in the ads? Doesn't streamlining improve every year?

The sorry answer is: not really. Back in the 1950s when the German NSU firm set motorcycle records at Bonneville, its engineers calculated that it would require 235 blip to push a naked motorcycle to 200 mph. And in fact today it requires a very strong-running, usually enlarged-motored Hayabusa or Kawasaki ZX-12 to reach 200 at Bonneville. Or a large amount of turbo boost (see “American Flyers,'' page 78). Conclusion? Things haven’t changed much. Not much can change when only the noses of motorcycles are streamlined, and front wheels stick out in the breeze like giant airbrakes.

Here arc some basics: When moving air exerts more pressure on the front of a vehicle than on the back, the difference is drag. In ideal streamlining, a moving vehicle pushes the air gently aside as if it were a million tiny springs and then the energy given to move those springs is returned back onto the smoothly tapered rear of the vehicle as it passes. No net energy is lost, so drag is zero. This perfection is never achieved but the best shapes get close. Unfortunately, typical motorcycle streamlining stops after accomplishing only the first half of this process. The fairing pushes the air aside, giving it energy in the process-but there is no smooth, tapering rear shape onto which the air can return this energy to the vehicle as it passes. Instead the air eddies and tumbles off the rear edges of fairing, screen and rider, forming a turbulent wake whose energy comes straight from the motorcycle’s engine. As a result, there is high pressure on the front of the machine, but low pressure on the back. The difference between them is drag-and in this case there is a lot of it.

Therefore, NSU’s 1950s estimate of 235 bhp to reach 200 mph will remain accurate until the whole aerodynamic job gets done. No matter what tricks are applied to the present front fairing with exposed front wheel, it must and will leave behind a large turbulent wake that eats major horsepower. No matter what origami-like shapes you fold into a motorcycle’s front fairing, no matter how many scoops and slots decorate it, today’s fairing is not modern and it is not high-tech. While it may be artistically styled, it is pitiful aerodynamically.

Then why are motorcycles shaped as they are? It is the result of long-ago racing politics and the public taste for fashion.

During the 1950s, German and Italian firms developed drag-reducing streamlining for roadracers. A first step was NSU’s hammered-aluminum beak-nosed front fairing with exposed front wheel. Because of the beak, it was promptly dubbed the “dolphin.” Later, NSU, Mondial in Italy and others added full enclosure of the front wheel, still leaving the rear of the machine naked. The resemblance of this style to an English dustbin gave it that name. Eventually, Mondial and others added tapering rear streamlining sometimes with a tail fin.

Full streamlining was banned by the F1M after the end of the 1957 season. Motorcycles have worn a shirt but no pants ever since both racing and sportbikes. Did the ban result from poor aerodynamics that caused instability or accidents? Maybe: If the center of pressure of the streamlining is ahead of the vehicle’s center of mass, any yaw (turn to right or left) produces a torque tending to flip the machine cnd-forend-like an arrow flying backward. Only Moto Guzzi had its own wind tunnel at the time, so certainly many of the shapes that ended up being raced were styled, not designed. Did spectators clamor for bikes that looked like stockers? Would you prefer a Formula One series whose racing ears looked like Toyota Corollas or Lincoln Continentals? Much of racing’s appeal is its violent contrast with the everyday-the noise, the speed and the far-out technical features.

Then why act to ban comprehensive streamlining? I suspect it was a combination of half-baked 1950s aerodynamics and the perennial need of organizations to “do something.”

Okay, but why should sportbikes remain forever stuck in 1958 aerodynamically? Sportbikes mimic GP bikes, and fashion has fixed this shape in our minds so that nothing else looks like a motorcycle anymore. This isn’t an engineering problem, it’s a social problem.

So, within the confines of this social problem, Greaves and associates first attempted to deal with the basic issues of drag on their Hayabusa. To test the shape of the bodywork, they trooped into the Ford-Sverdrup wind tunnel No. 8, in Allen Park, Michigan, and invited me along to sit in. The first task was the measurement of “A,” the frontal area, performed in eerie darkness by a robotic device that probed the outer margins of the vehicle’s shape w ith a light beam. Result: A = 7.790 square feet with rider.

No. 8 is an open-jet tunnel, meaning that the test article is supported on a platform in a large room, while a large jet of air is blown past it from a 110square-foot nozzle. This open format eliminates interaction between the test shape and the walls of the tunnel. We walked through the tunnel, sidling through its lofty turning vanes, up to the face of the huge fan, which made me feel like a mouse in a turbine. The platform, which can rotate to reveal yaw forces, measures drag and front and rear lift on the test article.

Moving air has kinetic energy proportional to the square of its speed. When this kinetic energy is fully converted into pressure by bringing the air to a full stop on the front of some obstruction, that pressure is called “Q,” the dynamic pressure. At one of our test speeds, 124.2 mph, Q was 36.8 pounds per square foot. Had the ’Busa’s frontal area been sawn out of a piece of plywood, presented flat-face to the wind, its drag would have been roughly its frontal area A (7.790 square feet), multiplied times Q (36.8 lbs./sq.-ft.), or 287 pounds. But rounded streamlining does not stop all the air that hits its

frontal area-it just slows it down somewhat. As a result, drag is less than Q would predict, and the measure of this drag reduction owing to shape is called the drag coefficient, or Cd. The actual drag measured in the tunnel was 140 pounds, about half of

that 287 figure. The ratio of the two, 140/287, is the Cd, which is 0.487. Cd measures how much the air “likes” the shape, and A just tells us how big that shape is. The smaller the Cd, the lower the drag. At the test speed, that 140 pounds of drag consumed 46 bhp.

What makes this work intoxicating is that if you cut either A or Cd by 10 percent, it cuts the power needed to push machine at a given speed by 10 > percent. Then you go faster. When John Britten did his aerodynamic development on a 20-mile straightaway in New Zealand, he found his best results by reducing A, which is why his VI000 was extremely narrow and had almost no fairing. When HarleyDavidson in 1969 contracted with Cal Tech for tunnel studies, they worked

primarily on Cd, resulting in a classic bulbous shape with its widest crosssection near the front (like a trout), using all remaining length behind that to pull the airflow inward to the smallest possible cross-section before chopping off the shape as racing rules required. Air loves the Cal-Tech fairing, but most people find it bulbous and tubbylooking. Even on little 250s this shape has significantly increased top speed. But air doesn’t buy motorcycles, people do, so fashion rules. What works aerodynamically takes a back seat.

Compare the .487 Cd of the Greaves bike/rider with the .17 of a 1944 P-51 Mustang aircraft, the .07 of a 1930s

zeppelin, or the .35 claimed for some recent autos. The .487 Cd figure is typical of sportbikes (also of highway trucks). Incidentally, with all bodywork removed but with rider, Cd became .6, about 24 percent worse. Using tape to continue the rider’s back as a smooth surface all the way to the seatback reduced Cd to .413-an improvement. How does this work? As air flows over the rider’s back, when it reaches a gap the flow separates, robbing the machine of its full pressure on a rear surface, and increasing the drag. Making the rider’s back and seatback one smooth surface kept the flow attached, bringing to bear a higher pressure on the rear> surface, decreasing drag. Racers try to keep this over-the-back flow attached by raising their backs on the straight just enough to feel their leathers press down on their skin, indicating flow at tachment. This can be worth 300 rpm-just the extra speed edge they need-at the end of a straightaway.

Think of the drag reductions we might achieve if we could keep the larg er flow along the sides attached in the same way. Can-Am did just this on its 1970s Bonneville 125cc record-breaker by use of a tail fairing that left only slots in its sides for the rider's legs. The sides of this afi fainng curved gently inward,

reducing the cross-section of the wake and providing surfaces against which the smooth pressure of attached flow could act. Think of this pressure on the angled sides and top of the machine as your hand, squeezing a wet bar of soap, making it shoot out of your grip.

Seeing the acceleration curves flatten off as they did at Brainerd, Greaves wondered if maybe top speed is limited by tire traction. Might downforce help? Racing cars use aerodynamic downforce to generate more traction for corner ing-enough that some cars could race on the ceiling. Why not see how much downforce could be generated by simple shapes on a motorcycle? He had there fore brought along a front wing and some "dustpans"-angled planes to be at tached at the rear axle ends. Cohn Lyster and the Suzuki Grand Prix team, among others, long ago tried similar schemes. Cars don't lean over in turns, so the downforce from a wing or underbody

venturi always acts downward, increas ing tire grip to boost corner speeds. On a bike, the thrust angle of any downforce device attached rigidly to it is the same as the angle of lean. As the machine leans over for a corner, the downforce devices begin to push the machine side ways, off the corner, as well as down ward. At 45 degrees of lean, the devices are trying just as hard to make the bike run wide as they are pushing downward. The two effects neatly cancel, leaving no gain. Greaves hopes that computercontrolled articulation of the wings to vary downforce and also to lift the inner wings upward during cornering would alleviate some of these difficulties, but this has proven problematic.

Also, downforce, even under the best conditions, isn’t free-there is always an associated level of drag. With automotive ground-effect devices, a typical lift/drag ratio is 4:1, so for every 100 pounds of downforce generated, 25 pounds of drag are added. To generate the 4000 pounds of downforce once common in F-l, the engine had to push 1000 extra pounds of drag. At 180 mph, this required an extra 480 bhp. That was no problem for a 1000-bhp GP car of the 1980s-they just dialed in more turbo boost. Greaves simply built a monster motor for his extra “boost.”

As our wind-tunnel testing contin-

ued, technicians fitted the “downforce dustpans.” At 124 mph, the resulting downforce was a modest 35 pounds at the rear. Cars win the downforce contest because (a) they have generous “plan” area (the view from the top) in which to implement it and (b) they don’t lean over for corners.

What does this mean? Must we keep the 1958 look forever? No, for as long

as there are people like Greaves and his sponsors, able to aim big research guns at the motorcycle’s problems, there is hope that engineering will not always be vetoed by fashion. Basic progress in motorcycle design needs more people tackling the fundamental problems:

1) “Half-fast" aerodynamics, as in front fairings but no other real streamlining. Airflow management has come a > long way since 1958. It's high time motorcycles caught up.

2) Wheelbase compromise: The longer (or lower) you make it, the harder you can accelerate and brake, but the slower it steers (or it grounds in corners). Several serious ideas on how to fix this actually exist. At least one-variable ride height-is about to be implemented.

3) While cars have 100 percent of their tires’ tread width on the ground all the time, motorcycles have only about 33 percent. That’s a serious shortfall. Think about it.

4) When leaned far over in turns, suspension move-

ment is mostly sideways. How can that absorb bumps? So far, our best “solution ” is crude buckboard-style chassis flex. Is that the limit of our ingenuity?

The mainstream has little incentive even to consider such problems because motorcycles currently meet the expectations of the market and sell. Therefore, the solution to these basic problems will come from the work of practical outsiders like Greaves, who are more interested in real answers that work than they are in fashion. □

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontIssue No. 500

August 2003 By David Edwards -

Leanings

LeaningsRiding the Cheyenne Breaks

August 2003 By Peter Egan -

TDC

TDCPressing Matters

August 2003 By Kevin Cameron -

Department

DepartmentHotshots

August 2003 -

Roundup

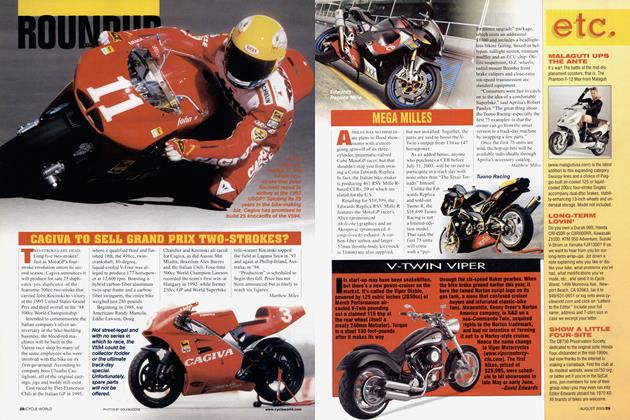

RoundupCagiva To Sell Grand Prix Two-Strokes?

August 2003 By Matthew Miles -

Roundup

RoundupMega Milles

August 2003