SERVICE

Paul Dean

Yetis on Harleys

Hypothetically, if you were to ride a Harley-Davidson equipped with its original-equipment Delphi electronic fuel-injection at sea level, then crate the bike and ship it up to 14,000 feet, how long would it take the EFI to adjust to the change? David Solomon

Posted on www.cycleworld.com

Interesting question, David, and the answer is that the system would adjust instantly. The moment the engine rumbles to life at 14,000 feet, the EFI system s various sensors are already feeding relevant data to the engine control module (ECM), which immediately calculates the proper fuel mixture for those conditions. There is no “memory ” involved, no period of running time required for the system to “learn ” the proper fuel mixture when ambient conditions are not the same as when the engine last ran. The ECM is preprogrammed with enough data to calculate and meter the correct amount of fuel under all the atmospheric conditions a rider will encounter, from well below sea-level to the highest roads through the tallest mountains. Motorcycle fuel-injection systems cannot adequately compensate for most engine modifications, but they can self-adjust for changes in altitude. This is due primarily to the system’s use of a MAP (manifold absolute pressure) sensor, which provides the ECM with the necessary air-density information to make the requisite calculations.

Understand, however, that fuel-injection systems do not permit an engine to produce the same amount of power at high altitudes as it does at sea level. Air gradually becomes thinner as elevation increases, and thus contains less and less of the oxygen that is so critical to combustion. Maintaining the correct mixture with less air means less fuel, which, in turn, results in less power. A carburetor, even a CV type, can't effectively compensate for dramatic reductions in air density\ but a fuel-injection system can. So, while carbureted engines usually puff black smoke at extremely high altitudes due to excessive mixture richness, a fuel-injected engine runs cleanly, even though its power output is significantly reduced.

Clearance clarified

I have a few questions about valves. Does valve clearance increase or decrease with engine wear? Should valve adjustments be made to the larger or smaller recommended clearance? Although it is hard to fault today’s rides, what is so difficult about incorporating self-adjusting valves into modern fourcylinder motorcycle engines?

John McQueen Denver, Colorado

For the most part, valve clearances tend to decrease over time. Once every two engine revolutions, the head of each valve slams closed against its seat, eventually hammering a slight ridge into the head and fattening its point of contact on the seat. Though wear in these areas is barely perceptible to the eye, it can be sufficient to allow the valve to retreat a few thousandths farther into the valve pocket, thereby reducing the clearance between the cam follower and the stem of the valve. How quickly this clearance loss occurs depends upon several factors, including the type and design of the follower system. Valve clearances sometimes increase, as well, due to wear beleen the cam lobe and cam follower, and beleen the follower and the top of the valve stem.

Although there is no accurate way to predict whether a valve will loosen or tighten over time, I prefer to adjust them closer to the larger of the recommended clearance values. If a valve gradually becomes too loose, it usually lets you know by emitting an audible ticking noise; when that happens, you know it's time to readjust it. But if the valve gradually tightens and concedes all of its clearance, you are not aware of the condition until the engine begins to lose power or misfire. At that point, the valve may already have been damaged beyond repair by the hot exhaust gases seeping past it. That ’s why I feel that favoring the loose side of the tolerance range is the safer of the two options.

By “self-adjusting ’’ valves, I assume you are referring to hydraulic tappets, such as used on Harley-Davidsons and automobiles, or hydraulic valve-lash adjusters like those on numerous Japanese cruiser engines. That ’s excellent technology for lower-rpm applications, but it ’s not at all suitable for modern high-performance four-cylinder engines, which rev to astronomical rpm levels. Some sportbikes have redlines that are as much as 2lh times higher than those on cruisers and cars. When these hydraulic devices are subjected to the number of opening and closing cycles that occur at engine speeds ranging from 10,000 to 15,000 rpm, they simply cannot keep up. Depending upon their specific design and location, they either “pump up,’’ which tends to prevent the valves from fully closing, or “pump down,’’ which prevents the valves from fully opening. Either way, the end result is greatly reduced perj'ormance.

Some like it hot

After installing new Metzeier Sportec M-l tires on my 2002 Honda Interceptor, I went for a test ride and noticed an increase in road noise. I assumed it was caused by the Metzelers, which are noisier than the Dunlops I had removed. I stopped and checked the front end anyway, including the clearance between the front-brake pads and their rotors, just to be sure that everything was tight and the calipers were not dragging. Everything seemed okay, so I then went for another short ride (3 miles with several in-town stops), then got off and touched each rotor to see if there was any excess heat that would indicate a dragging brake pad. 1 was surprised to find that the right-front rotor was barely warm, the left-front rotor was noticeably hotter, and the rear rotor was very hot to the touch. None of the rotors was red-hot, but 1 had only ridden 3 miles at around 45 mph. Both wheels seem to spin freely, so is this heat differential normal or an indication that something is wrong with the brakes? D. Bradley Horton

Thousand Oaks, California

In all probability, nothing is wrong with your Interceptor s brakes; such variations in rotor temperature are not unusual. When the brake lever or pedal is released after use, the pressure in the brake system is relieved; but since there is no device in the system to draw the caliper pistons back inside the caliper, the brake pads do not retract and instead continue to make light contact with the rotor. This is referred to as the pads “kissing” the rotor.

There is no hydraulic pressure acting on the backsides of the pistons, however, so although the friction of kissing can generate a bit of heat in the rotors, it does not produce any significant braking force.

The amount of heat created in any rotor is dependent upon how hard its pads kiss it. Differences in the fit of each caliper piston in its bore, or the snugness of its neoprene seals, or the amount of accumulated brake dust and road grime around the piston bore, all can affect how much each piston “relaxes ” when the brakes are released. There also can be differences in how well each

rotor is centered in its caliper. Even minute differences in these factors can result in discernable variations in the temperature of individual rotors.

A logical person might ask why brake manufacturers do not incorporate some kind of retraction device in the caliper that would pull the pads farther away from the rotor? Actually, that tactic has been tried, but it tends to cause the brake lever/pedal to have too much freeplay before it engages the brake. If the pistons are pulled even a short distance back into the caliper bores, they then require the movement of more fluid to push them back out to the rotors. That can only be accomplished by additional lever/pedal movement that is too great to allow com plete and comfortable brake application. Many brake manufacturers used to in clude retractors in their disc-brake sys tems but ultimately concluded that they could achieve better braking without them, and that allowing the pads to kiss the rotors was not problematic.

fF(DS4Ok~

In the April issue, Jim Franks wrote to you about his Honda CBR900RR dying in the rain (“Rain of terror”). My Honda Super Hawk had symptoms identical to those on Jim’s CBR, and the problem was that the carburetor drain and vent lines were routed to a location under the engine where they would suck up water spray from the front tire. The solution was to move the lines to a dry area inside the fairing. Ta-da! No more problems. Please pass this on, and keep up the good work. Steve Rodrigues

Brisbane, California

Thanks, Steve. I don’t know whether or not your suggestion will remedy the stalling problem with Jim’s 900RR, but when people get desperate enough, they’re usually willing to try anything to make a problem go away. And Franks seemed pretty desperate at the time. If it works, maybe he’ll ride up the road from Murrieta to Brisbane and buy you a cold one.

Plavinci the percentaqes

1 am contemplating a sprocket change on my 1997 Honda CBR1100XX and could use your help. I need the formulas to figure out what a change in sprocket size will do to the bike’s engine rpm at cruising speed (about 85 mph), and what will happen to the top-end performance. Any help you can offer will be greatly appreciated. Ridley R. Reese

Houston, Texas

Even though 1 've answered this question a couple of times in the past, I continue to get so many inquiries on the subject that I feel compelled to deal with it yet again. There really is nothing as complex as a "formula ” involved here; all that s required is simple math and the knowledge that the percentage of change in the bike s road speed or rpm in any gear will be exactly the same as the percentage of change in the final-drive ratio.

According to our test of the 1997 XX, the engine spins at 3624 rpm at 60 mph in top gear. This means that for every 1000 rpm of engine speed, the bike goes 16.55 mph (60 + 3.624 = 16.55) in top gear. Consequently, 85 mph will have it turning 5136 rpm (85 +16.55=5.136). So, using round numbers to make things simple, let’s suppose the Blackbird had final gearing of 48/16 (a ratio of 3.0:1), and you decided to add three teeth at the rear (51/17, a ratio of 3.1875:1). That increase of 0.1875:1 is 6.25-percent (0.1875+3.0=0.0625) lower than stock, which means engine rpm-in any gear and at any speed-will be 6.25-percent higher. In top gear at 85 mph, the engine will then be turning 5457 rpm, an increase of 321 revs. It makes no difference if the final gearing is made > taller or shorter; the percentage of change in the gearing and the percentage of change in rpm at any speed in any gear are always the same.

As far as gearings effect on “top-end performanceI'm not sure what you mean by that. The XX already goes 174 mph with stock gearing, so I assume you 're not looking for more top speed. If you re talking about the bike s acceleration at higher speeds, the same equal-percentage principle applies: The percentage of increase or decrease in rear-wheel torque is the same as the percentage of increase or decrease in the gearing. Rearwheel torque is the torque made by the engine multiplied by the overall gear ratio. If the overall top-gear ratio (calcu-

Recall Roster

NHTSA Recall NO.03V111 Victory Standard Cruiser, Deluxe Cruiser, Touring Cruiser, Deluxe Touring Cruiser Model year: 2002

Dates of manufacture: Dec. ’00-May ’02 Number of units involved: 1786 Problem: On certain motorcycles and under certain conditions, the outlet port of the fuel pump may dislodge from the pressure-regulator housing, reducing fuel pressure at the fuel rail and causing the engine to stall, increasing the risk of a crash.

Remedy: Dealers will rework the fuel pump to prevent it from dislodging. Owners who do not receive the free remedy within a reasonable time should contact Victory at 763/417-8650.

lated by multiplying the primary ratio by the intermediate ratio-if applicable-times the transmission top-gear ratio times the final-drive ratio) is, for example, 4.5:1, the torque made by the engine is multiplied by 4.5. On the XX, the torque peaks at 80 ft.-lb. at 7500 rpm; so that works out to 360 ft.-lb. at the rear wheel in top gear, less frictional losses in the drivetrain, of course. And if using our previous example, the final-drive gearing were raised by 6.25 percent, so too would peak top-gear torque at the rear wheel be increased by 6.25 percent to 382.5ft.-lb.

Ted’s at it again

I have a really nice ’83 Honda CB1100F that needs a little help. I changed the exhaust to a SuperTrapp, which is a lot lighter than stock, then removed the stock airbox and replaced it with four individual air cleaners. The engine now seems to run very lean, even though I have increased the main-jet size from 122 to 140. The plugs still are white, yet when I gas it, black smoke comes out the exhaust as though it is too rich. What gives? Ted Smith

Salt Lake, Utah

Here’s the problem in a nutshell: The main jets are way too big, making the full-throttle mixture too rich, and the metering needles in the carbs are too lean. The engine therefore runs lean everywhere but at full throttle, causing the sparkplugs to burn white. In stock form, the main jets in the CBl I OOF’s CV carbs were pretty close to ideal, but the needles and the throttle slides were calibrated with lean jetting to help the engine meet the emissions regulations of that era.

When you removed the airbox and installed four individual air filters, you made the partial-throttle leanness even worse. Actually, with stock main jets, the full-throttle mixture also probably would have been excessively lean; but you overcorrected the main jetting by jumping 18 sizes, making the full-throttle jetting excessively rich.

The rational solution here is to install an aftermarket jet kit calibrated for your motorcycle. Dy nojet (www.dynojet.com) sells one for $122 (part HI 105), and it contains the correct main jets, needles, needle spacers and instructions for installation. Œ

Got a mechanical or technical problem with your beloved ride? Can’t seem to find workable solutions in your area? Maybe we can help. If you think we can, either: 1) Mail your inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/631-0651; 3) email it to CW1Dean@aol.com, or 4) log onto www.cycleworld.com and click on the Feedback button. Don’t write a 10-page essay, but do include enough information about the problem to permit a reasonable diagnosis. And please understand that due to the volume of inquiries we receive, we can’t guarantee a reply to every question.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontIssue No. 500

August 2003 By David Edwards -

Leanings

LeaningsRiding the Cheyenne Breaks

August 2003 By Peter Egan -

TDC

TDCPressing Matters

August 2003 By Kevin Cameron -

Department

DepartmentHotshots

August 2003 -

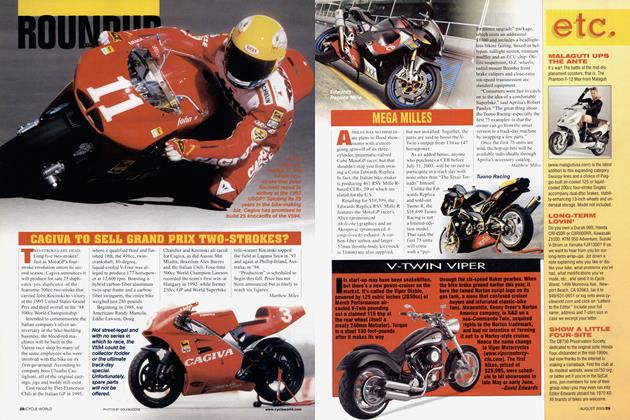

Roundup

RoundupCagiva To Sell Grand Prix Two-Strokes?

August 2003 By Matthew Miles -

Roundup

RoundupMega Milles

August 2003