TDC

Equal shares

Kevin Cameron

How DO YOU KNOW THAT EACH OF THE cylinders of a multi-cylinder engine is operating at its best? How do you know if each receives the same intake airflow or the same fuel mixture strength?

Maximum power is given when each cylinder receives an air/fuel mixture close to 12.5 to 1. Let’s say we have two cylinders actually receiving that, while cylinder three gets a lean 15:1 and the last cylinder gets an over-rich 11:1. Two cylinders are making their maximum, but the lean and rich cylinders are falling short by a couple of horsepower each. With this engine running on a dyno, the calculation resulting from fueland airflow numbers would tell us the mixture is correct. As an average it is, but we know the engine is down on power.

How can we correct this? The old way was to “read” the mixture from the sparkplugs and then “stagger-jet” the carburetors accordingly. For example, because of the way the 1970-71 Kawasaki Hl-R racing two-stroke Triple vibrated, its wildly shaking left carburetor required a #320 mainjet, its fairly active right carburetor a #310 and the quiet center a #300.

The new way uses oxygen sensors in the exhaust (this is because computers haven’t learned to read plugs). A couple of years ago, I watched Mat Mladin’s Yoshimura Suzuki GSX-R750 being wheeled onto pit lane before a Daytona practice. There was a plugged, threaded receptacle welded into each of the four header pipes. Why? Engineers wanted to know the mixture strength received by each individual cylinder, and a single oxygen sensor screwed into the collector pipe would give only averaged information. Only after the tuning of individual cylinders is corrected can a single oxygen sensor report the engine’s overall mixture strength.

For a time there was a fad for drilling a quarter-inch hole in hot-rod V-Eight car engine headers. The reason was that uninformed persons had seen such holes in the headers on some NASCAR engines and had assumed they somehow enhanced performance. The actual reason for the holes was to allow fitment of exhaust-gas temperature probes during dyno running. Equal temperatures on all eight would mean that all cylinders were receiving about the same mixture. Variations would show that more tuning was needed.

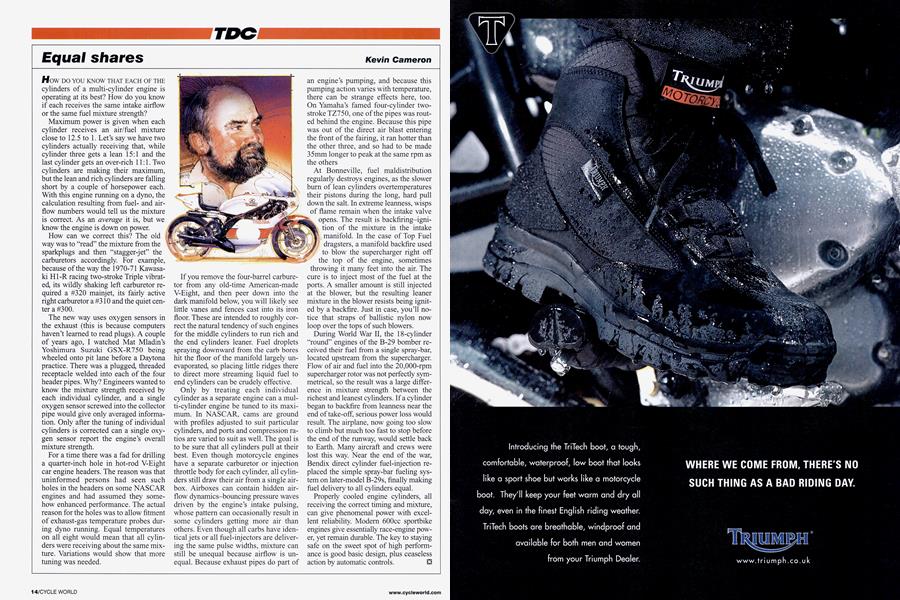

If you remove the four-barrel carburetor from any old-time American-made V-Eight, and then peer down into the dark manifold below, you will likely see little vanes and fences cast into its iron floor. These are intended to roughly correct the natural tendency of such engines for the middle cylinders to run rich and the end cylinders leaner. Fuel droplets spraying downward from the carb bores hit the floor of the manifold largely unevaporated, so placing little ridges there to direct more streaming liquid fuel to end cylinders can be crudely effective.

Only by treating each individual cylinder as a separate engine can a multi-cylinder engine be tuned to its maximum. In NASCAR, cams are ground with profiles adjusted to suit particular cylinders, and ports and compression ratios are varied to suit as well. The goal is to be sure that all cylinders pull at their best. Even though motorcycle engines have a separate carburetor or injection throttle body for each cylinder, all cylinders still draw their air from a single airbox. Airboxes can contain hidden airflow dynamics-bouncing pressure waves driven by the engine’s intake pulsing, whose pattern can occasionally result in some cylinders getting more air than others. Even though all carbs have identical jets or all fuel-injectors are delivering the same pulse widths, mixture can still be unequal because airflow is unequal. Because exhaust pipes do part of an engine’s pumping, and because this pumping action varies with temperature, there can be strange effects here, too. On Yamaha’s famed four-cylinder twostroke TZ750, one of the pipes was routed behind the engine. Because this pipe was out of the direct air blast entering the front of the fairing, it ran hotter than the other three, and so had to be made 35mm longer to peak at the same rpm as the others

At Bonneville, fuel maldistribution regularly destroys engines, as the slower burn of lean cylinders overtemperatures their pistons during the long, hard pull down the salt. In extreme leanness, wisps of flame remain when the intake valve opens. The result is backfiring-ignition of the mixture in the intake \ manifold. In the case of Top Fuel dragsters, a manifold backfire used to blow the supercharger right off the top of the engine, sometimes throwing it many feet into the air. The cure is to inject most of the fuel at the ports. A smaller amount is still injected at the blower, but the resulting leaner mixture in the blower resists being ignited by a backfire. Just in case, you’ll notice that straps of ballistic nylon now loop over the tops of such blowers.

During World War II, the 18-cylinder “round” engines of the B-29 bomber received their fuel from a single spray-bar, located upstream from the supercharger. Flow of air and fuel into the 20,000-rpm supercharger rotor was not perfectly symmetrical, so the result was a large difference in mixture strength between the richest and leanest cylinders. If a cylinder began to backfire from leanness near the end of take-off, serious power loss would result. The airplane, now going too slow to climb but much too fast to stop before the end of the runway, would settle back to Earth. Many aircraft and crews were lost this way. Near the end of the war, Bendix direct cylinder fuel-injection replaced the simple spray-bar fueling system on later-model B-29s, finally making fuel delivery to all cylinders equal.

Properly cooled engine cylinders, all receiving the correct timing and mixture, can give phenomenal power with excellent reliability. Modem 600cc sportbike engines give essentially race-engine power, yet remain durable. The key to staying safe on the sweet spot of high performance is good basic design, plus ceaseless action by automatic controls. □