SERVICE

Paul Dean

A shaft in the rear or a belt in the back?

I am considering buying either a Yamaha Road Star, which has a belt final drive, or a Yamaha Royal Star, which has a shaft drive. What are the advantages and disadvantages of shaft drive versus belt drive for a recreational rider? Which costs more to repair and which is more reliable? Scott Wattawa

Posted on America Online

A belt drive is lighter, which translates into less unsprung weight, and that, in turn, generally results in a better ride. Belt drives are more efficient in terms of frictional power losses between the transmission and the rear wheel, and are less expensive to manufacture, replace or repair. In some cases (such as with HarleyDavidsons, for which there are several OEM and aftermarket pulley sizes available), belts permit relatively cheap and easy changes in the final-drive ratio. With most shaft drives, you ’re stuck with the existing ratio; and even when an alternative gearset or two is available, the swap is a more expensive and involved process. On the other hand, shaft drive is more reliable and could very easily outlast the rest of the motorcycle, whereas a belt will wear out and need periodic replacement, just as it will also likely require the occasional adjustment. And the torque reaction of shaft drives can induce some rather undesirable chassis dynamics, although certain systems-such as BMW’s Paralever final drive-eliminate this problem altogether.

If you want my advice, buy the Yamaha you like the most and don’t worry about its final-drive configuration. One way or another, the means by which the power is delivered to the rear wheel is not likely to be a significant issue during your ownership of the bike.

Breathing easier

I want to install a set of Harley-Davidson Screamin’ Eagle mufflers on my 2001 FLHT Electra Glide Standard. My engine is 100 percent stock, including the original 40mm Keihin carburetor. Will I need to re-jet the carburetor after installing these mufflers? I do not plan to make any other modifications to the engine-i.e., air cleaner, pistons, etc. Geoffrey Jones Posted on www.cycleworld.com

You won ’t need to re-jet the carburetor or make any other modifications, but if you want to earn the best performance from your switch to the Screamin ’ Eagle mufflers, you should. Like all modern motorcycles, Harleys arrive from the factory with very lean jetting made necessary by their need to comply with the EPA’s exhaust emissions regulations. Furthermore, the bikes are equipped with very restrictive intake and exhaust systems that allow them to meet federal standards for noise emissions. When you allow the exhaust gases to exit more freely by bolting on less restrictive mufflers, you really should do likewise with the intake tract by installing a less restrictive air cleaner. And that, in turn, calls for a recalibration of the carb, most logically with one of the company’s Screamin ’ Eagle Thunderslide kits. We ’re not talking about a King’s ransom for these pieces, and the performance boost they provide makes them well worth their meager expense.

Adding fuel to the fire

I recently bought a 1993 Suzuki GS500 with 3600 miles on the odometer. The guy I bought it from had owned it for quite a while and said that it never ran right. I took it off his hands for a grand, noticing that the rubber boot between the airbox and the left carburetor was half off. I fixed that once I got it home and even cleaned up a lot of gas that had accumulated in the airbox. It started okay and will run good once it is revved up past about 5000 rpm, but it sputters and bogs and hesitates at lower rpm. Does this mean that the jets need to be cleaned? If so, what does that involve? Jeremy Brekken

Portland, Oregon

Even when brand-new, GS500 Suzukis are notoriously cold-blooded machines that usually won’t run and respond decently until they’ve been ridden 20 to 25 miles. The engine is an old, two-valve, air-cooled design that started life as a 400 in 1977, was later enlarged to a 450 and eventually stretched to a full 500, but it still uses combustion-chamber technology that is nearly 25 years old. Thus, the only way the engine has been able to meet latter-day emissions standards is with ultra-lean carburetion that is marginal even when the engine is fully warmed.

I can’t say for sure if your GS500 s jets are clogged and need to be cleaned, but there ’s a better solution in any event: Eighty-six the stock jets and replace them with those from an aftermarket jet kit. Dynojet, K&N and Factory all make such kits for the GS500, and their installation will greatly improve the bike ’s throttle response, warm-up time and overall engine performance.

Two outta three ain’t bad

I currently own a 1999 Triumph Legend 900, which has been a pleasure to own and ride, but I do have three complaints: 1) Needs a sixth gear; 2) fork springs are mushy; 3) rear shock is mushy. I know I can’t do anything about Number One, but as far as the other two are concerned, are there any aftermarket fork springs and shocks available for these bikes?

Bryan Gomes Posted on www.cycleworld.com

Race Tech (909/594-7755) has springs available for the Legend’s fork, and it also offers its very effective Cartridge Emulators, which embue the front end with improved damping qualities that nicely complement the stiffer springing.

Works Performance (818/701-1010) specializes in building custom-tailored shocks to fit virtually any motorcycle, including your Triumph. By working with these two companies, you should be able to re-tune your Legend ’s suspension to more closely meet your riding needs.

A Wing and a prayer

My ’82 Honda Gold Wing Interstate recently needed new tires, and after shopping around, all I could find in the recommended sizes were two rear tires. In other words, the front tire was the correct size but was meant to be on the rear of a smaller bike. The guy at the shop said the tire would work just fine but that because it was a rear tire, it would need to have the tread aimed in the opposite direction if mounted on the front. I agreed, but when I got the bike back, the tire had been mounted with the tread aimed as it would have been if used as a rear tire. I decided to just ride the bike rather than going through the trouble of changing the tire. Am I at risk in any way from tire failure? Incidentally, the bike handles fine.

Marv Bowman Posted on America Online

There’s a lot more to think about here than just the direction of the tread pattern and the fact that the rear tire you are using is the same size as the front tire you replaced. But, since you provided no details about the tire in question (brand, model, size, etc.), I can’t be very specific about your particular application.

First of all, the load rating of a rear tire meant for a smaller motorcycle is likely to be considerably less than that of a front tire intended for a heavyweight touring machine. It’s conceivable, then, that the tire you currently have on the front of your Wing is overloaded when you ’re riding two-up with the luggage fully packed. What ’s more, the construction of front and rear tires is not the same. A front tire ’s primary role is to provide favorable steering feel and accuracy, with good stability under hard braking; rear-tire construction centers more around controllable delivery of power to the ground at all reasonable lean angles. The same could be said for the tread pattern, which, on front tires, often is specifically designed for stable steering on grooved pavement. And the tread’s ability to channel water out from under the tire in the rain also is an important design characteristic. Some tread patterns do this more effectively in one direction than the other, meaning that mounting the tire “backwards ” can allow hydroplaning to occur at lower speeds than if the tire were mounted correctly.

Many tires, radiais in particular, are directional for reasons that may not necessarily involve tread pattern or profile. The carcasses and belts are built with layers that overlap in one direction; consequently, forces acting on the tire in one direction of rotation will try to loosen the layers and delaminate them, whereas forces in the other direction will effectively try to tighten the layers and keep them intact. Since the greatest forces at the rear wheel (driving) are opposite of the greatest forces at the front (braking), the tires are directional, with arrows molded into their sidewalls that denote the proper orientation for frontor rear-wheel use.

A mind is a terrible thing

After reading your reply to Dennis Pinke’s letter (“It’s the novocaine”) in the July issue, I’m confused. You stated that shortening an engine’s connecting rods while leaving everything else the same helps increase torque output, but everything I’ve ever read has always claimed exactly the opposite: that lengthening the rods increases torque. I’ve even built several examples using construction paper and each has demonstrated that a longer rod causes the Instance of 90 Degrees to occur higher in the cylinder bore. So, what’s up with this? Am I missing something here? Robert R. Shaw

Elgin, Illinois

You re not missing a thing, Robert, but an entire squadron of my working brain cells apparently has gone AWOL. You are absolutely correct: Longer connecting rods, not shorter ones, can help some engines produce slightly more torque.

I fully understand this long-rod/shortrod equation: I’ve built numerous longrod engines for this very purpose. But I wrote my reply right at our final deadline, amidst a whirlwind of other unrelated activities that were a lot more distracting than I realized at the time, and I simply forgot to turn on my brain. The result is a classic example of what can happen when a person deludes himself into believing that he knows something so well that he doesn’t have to actually think about it. That’s certainly no excuse for such an egregious error, but it is a reason.

This was an embarrassing, unforgivable faux pas on my part, and I offer my sincere apologies to anyone who might have been confused by it. As a punishment, my colleagues here have sentenced me to 30 sharp raps across the knuckles with a long connecting rod...or was it a short one?

Hi, anxiety

The odometer on my new Honda VTX 1800 just hit 600 miles. Your test of this bike was dead-nuts on! It puts a grin on my face no matter how bad my day has been. I do have two questions, though. After the engine is warmed up and I accelerate in first gear, it acts like it runs out of gas. When I shift into second gear and accelerate, it revs up fine. This only happens in first gear. Could this be a fuel-injection problem or is there a rev-limiter on this bike? It doesn't have a tach, and I don’t want to launch a rod through the block.

Also, with the bike running but stopped and in first gear, if I let the clutch out quickly with very little throttle, I hear a pretty good clunk. If I take off normally (more throttle, slower clutch engagement), I hear nothing. Could this be due to pinion-gear/ring-gear backlash in the final drive? Did you experience either of these conditions with your test VTX 1800?

Rob Phillips Parish, New York

Don’t worry, there is nothing wrong with your VTX. The behavior you describe is perfectly normal. What you are experiencing in first gear is a phenomenon we also noticed with our testbike. The engine is surprisingly quick-revving, despite its enormous flywheels, but it has a rather low first-gear ratio as well as a low redline (just 5500 rpm, with a rev-limiter that cuts the flow of fuel to the injectors at 5800 rpm). This combination of design elements causes the engine to hit the rev-limiter so quickly in first gear that it gives the impression of shutting down prematurely. But if the VTX had a tach, you would see that it indeed does reach max rpm in first. The ratio in second is significantly taller, so the engine takes much longer to reach the rev-limiter in that gear, and even more so in the other three.

As far as the clunking noise is concerned, that too is normal. The VTX has five separate damping systems strategically located throughout its driveline, and quickly engaging the clutch-even at idle-causes the freeplay in all of those dampers to be taken up abruptly, resulting in the noise you hear. Actually, if you engage the clutch in that fashion on just about any bike, you ’ll get the same kind of noise as all the slack in the driveline is quickly taken up.

Got a mechanical or technical problem with your beloved ride? Can’t seem to find reasonable solutions in your area? Maybe we can help. If you think we can, either: 1) Mail your inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/631-0651; 3) e-mail it to CW1Dean@aol.com, or 4) log onto www.cycleworld.com and click on the Feedback button. Always include your name, along with your city and state of residence. Don’t write a 10-page essay, but do include enough information about the problem to permit a reasonable diagnosis. And please understand that due to the huge volume of inquiries we receive, we can’t guarantee a reply to every question.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

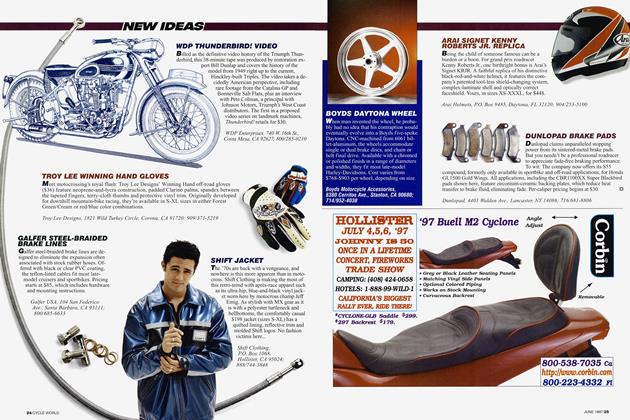

Up FrontSpanish Flyers

September 2001 By David Edwards -

Leanings

LeaningsAncient Beemer Update

September 2001 By Peter Egan -

TDC

TDCTurning

September 2001 By Kevin Cameron -

Departments

DepartmentsHotshots

September 2001 -

Roundup

RoundupYamaha Unleashes Bulldog V-Twin!

September 2001 By Matthew Miles -

Roundup

RoundupNew Life For A Legend

September 2001 By Matthew Miles