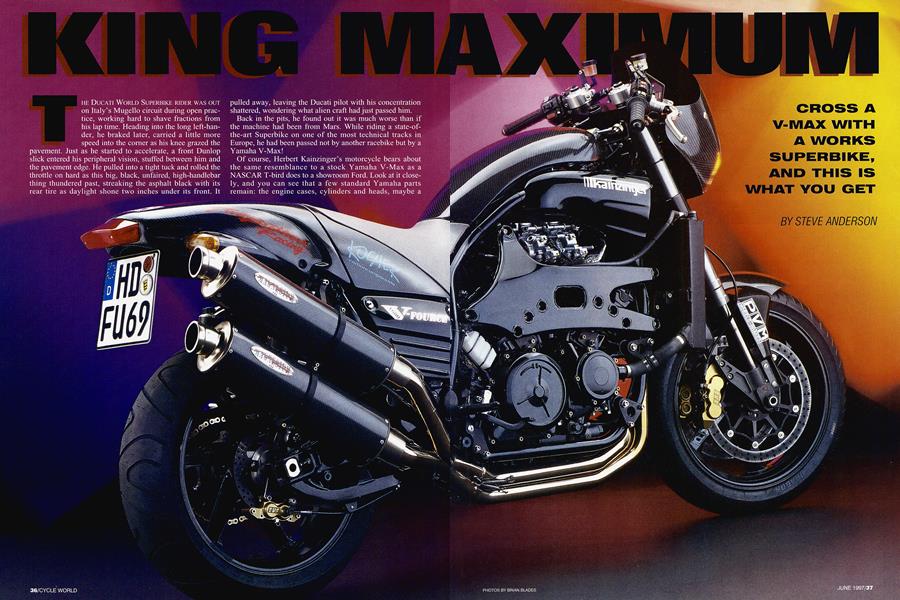

KING MAXIMUM

THE DUCATI WORLD SUPERBIKE RIDER WAS OUT on Italy's Mugello circuit during open practice, working hard to shave fractions from his lap time. Heading into the long left-hander, he braked later, carried a little more speed into the corner as his knee grazed the pavement. Just as he started to accelerate, a front Dunlop slick entered his peripheral vision, stuffed between him and the pavement edge. He pulled into a tight tuck and rolled the throttle on hard as this big, black, unfaired, high-handlebar thing thundered past, streaking the asphalt black with its rear tire as daylight shone two inches under its front. It pulled away, leaving the Ducati pilot with his concentration shattered, wondering what alien craft had just passed him.

Back in the pits, he found out it was much worse than if the machine had been from Mars. While riding a state-ofthe-art Superbike on one of the most technical tracks in Europe, he had been passed not by another racebike but by a Yamaha V-Max!

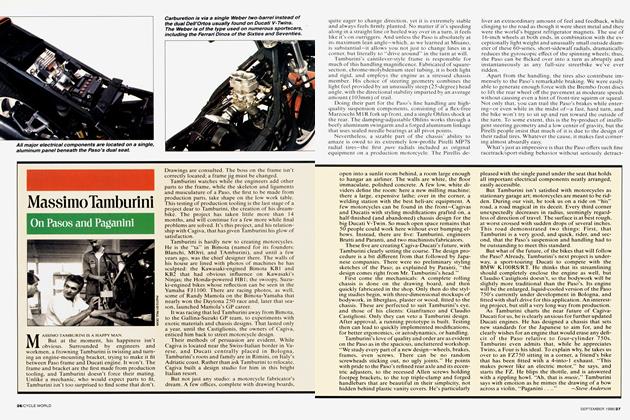

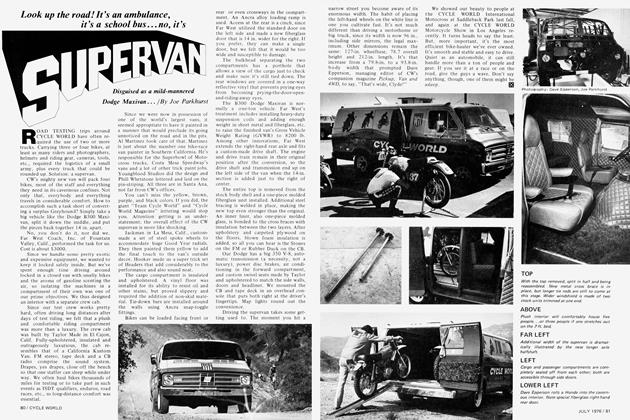

Of course, Herbert Kainzinger’s motorcycle bears about the same resemblance to a stock Yamaha V-Max as a NASCAR T-bird does to a showroom Ford. Look at it closely, and you can see that a few standard Yamaha parts remain: the engine cases, cylinders and heads, maybe a frame tube or two. Everything else is new, and comparable in quality and intent to what you’d see on the front row of a World Superbike grid.

CROSS A V-MAX WITH A WORKS SUPERBIKE, AND THIS IS WHAT YOU GET

STEVE ANDERSON

That’s not too surprising because Kainzinger was involved with high-level roadracing for years before getting into hot-rod V-Maxes. He had been chief mechanic for serious 125cc GP efforts (third place in the ’91-92 GP season), built World Superbikes, tuned for efforts that won three German National Championships and wrenched for Helmut Bradl the year he got second in the European 250cc Championship. But after years of competition, Kainzinger left roadracing to open his own streetbike tuning business. Why? Just one reason, he explains, rubbing his fingers together-money. There’s a select group of wealthy German riders who’ll pay big bucks for well-engineered and uniquely fast Kawasaki ZX-1 Is and Suzuki GSX-R1100s.

Kainzinger certainly had the expertise to build big-bore inline-Fours that made power and held together, and soon enough he was figuring out how to cram 80mm bores into densely packed Kawasaki cylinder blocks. Besides, it beat

rebuilding engines in the back of a van in some rundown racetrack in Eastern Europe at 2 in the morning.

It was after he started his tuning business that a friend kept coming by asking him to take a look at his V-Max, which was just too slow for his tastes. For a long time,

Kainzinger made excuses, not wanting to work on a “chopper.” Finally, the excuses ran out and he took on the project. What he found shocked him. “It’s really hard finding big power in a GSX-R or a ZX-11-you have to work hard for your gains. But the V-Max is an old engine, and it’s easy to improve. Just bolting on flat-slides and a good exhaust system yields incredible torque. The more I worked on it, the more I was impressed with the engine.”

Kainzinger was so impressed that he went out and bought a wrecked V-Max for himself and began to build the bike you see pictured here. As he points out, “Finding more power is the easy part; the problem is more to handle the power.” So the V-Max chassis in its standard shaft-drive, rakedout form had to go. The front end was relatively easy: The steering head was cut away, and a new one put in its place.

Instead of the cruiser-like rake and trail numbers of the stocker, the new steering head was angled at 24 degrees (plus or minus one degree by changing bearing carriers), which, in conjunction with a special, longer-than-usual WP fork and a 17-inch front wheel and tire, yielded a trail of 3.7

inches-both figures right on the cutting-edge of sportbike mainstream. The new head angle also pulled the front wheel right up against the engine, cutting 4.5 inches from the wheelbase while producing a more desirable 52/48 percent weight distribution, similar to the front-heavy design of current Superbikes.

Eliminating the shaft drive was more involved. The frame was given new tubes in this area to make room for the chain, and a new swingarm, modeled after the latest 500 GP arms, was built. But how to attach a sprocket to the V-Max engine? Kainzinger’s solution is both high-tech and ingenious.

Fortunately, the transmission countershaft rotated in the right direction for chain drive. Kainzinger utilized the standard countershaft, and had an already case-hardened sprock-

et electro-discharge machined (EDMed) for a splined center hole that could mate with the countershaft splines that normally carry a right-angle gear. Ele whittled from billet a bolt-on aluminum structure that supported the end of the countershaft in a totally sealed bearing (just like a wheel bearing) so he didn’t have to supply oil to this area. And finally, he had female threads EDMed into the end of the countershaft itself so a bolt and spacer could hold the sprocket in place. Instant chain-drive V-Max.

The bike’s dimensions were getting interesting, as well. That new swingarm was made 2 inches shorter than the standard arm, and combined with the changes to the front end, reduced the wheelbase to just 55.9 inches-as short as some 600s. Kainzinger believes that “less weight and less friction are

the biggest performance improvements you can make. Take weight and friction away and you don’t have to push to the mechanical edge with the highest-lift cams and the highest compression ratio.” So every fastener, save for the connecting-rod bolts, was replaced by a titanium or aluminum equivalent. The V-Max’s under-seat gas tank was redone in carbon-fiber, as were the seat pan and airbox/carburetor cover. Any rubber bushings were removed from the engine mounts, and big aluminum X-members were fabricated to bolt to frame and engine to tie them rigidly together. One of these serves as a catch tank.

Kainzinger also lightened the alternator, strategically trimmed the crankcases and fabricated the exhaust system from titanium, adding carbon-fiber mufflers and magnesium end caps. The result is a bike no bigger than a Honda CBR900RR that weighs just 422 pounds wet; a bike that was measured at the local technical university in Germany

to be torsionally stiffer than a 1996 Kawasaki Superbike; a tiny bike that carries a V-Max engine.

And not just any V-Max engine. It’s one that Kainzinger reserved for his own motorcycle, one that displaces not 1200, not 1300, but 1680cc, an engine as trick as that in any works racer. Start with the intake system: Custom air scoops really pressurize the airbox-unlike the fake scoops of a stocker-and feed the latest 41mm downdraft flat-slide Keihins. Fuel/air mix flows down through thoroughly modified cylinder heads, past big 32.5mm titanium intake valves with skinny 5mm stems. Pulling the mixture down are huge, 90mm pistons.

After working with inline-Fours, Kainzinger loves the generous bore-spacing that Yamaha has given the V-Max, which allows such enormous increases. Not that bores the size of drain pipes are easy to engineer. The 90mm bore actually extends beyond the stock iron liner, even beyond the aluminum that supports it. So Kainzinger machines the stock cylinders away to a depth of 64mm from the top of the block, and replaces them with Nikasil-coated aluminum cylinders that run wet, directly in the coolant.

Not only do the new aluminum liners allow the huge bores, they also offer the possibility of less friction by requiring less piston-ring pressure for sealing. Pankl, the same company that builds automotive F-l and Ducati works Superbike rods, supplies the H-beam titanium connecting rods that carry the big pistons. The compression ratio was boosted to a very racy 13.6:1, while the stock cams were reground for a generous 260 degrees of intake duration and 248 degrees of exhaust.

These long durations are tolerable because the intake system and carburetors are still relatively undersized for the enormous displacement, and because they produce high, midrange-enhancing intake velocities. About the only things Kainzinger left stock were the crankshaft and transmission, though those parts were thoroughly examined and magnafluxed before finding their way into this engine.

Even the cooling system is part of the horsepower equation. Starting with a radiator from a BMW 528 car, Kainzinger bends and modifies this giant heat exchanger to fit, and then reroutes flow paths so that coolant flows evenly into cylinder heads first, and then out at the base of the cylinders-the reverse of normal street practice. Why? Because racing has demonstrated the benefits of increased charge density and more detonation resistance from cool heads. “I don’t ever want to see more than 70 degrees Celsius (about 160 F),” says Kainzinger, pointing out you can see similar cooling designs in F-l engines.

So how much power does this mega-Max make? Kainzinger estimates the 1680cc engine should twist the dial at about 240 rear-wheel horsepower, though he has yet to put it on a dyno. The engine he ran in this bike last year was the smaller-bore, 1520cc version he builds for customers. Kainzinger says it tested at 210 horsepower at 9100 rpm, with a torque peak at 6000. Given normal cylinder pressures for similarly tuned engines, those numbers are right in the range of believability. At 420 pounds and over 200 horsepower, this V-Max should accelerate almost as hard as a 500cc GP bike and harder than any Superbike.

Unfortunately, we had neither opportunity to ride the bike nor put it on the dyno because an unheated Lufthansa cargo bay led to coolant freezing on the bike’s flight to the United States, which popped seals and prompted a quick trip back to Germany for repairs.

But if we were unable to be stunned by the acceleration of Kainzinger’s Max, we could still be stunned by his attention to detail. Everywhere you look are parts that would look at home on the front row of a Superbike race; things like the PVM six-piston brakes and the straight-from-the-GP-grid master cylinders. It’s the perfect carbon-fiber bodywork, the titanium fasteners and the clever chain-drive conversion. And, of course, it’s the stunning $80,000 that Kainzinger would charge for an exact replica.

Kainzinger doesn’t really expect his phone to ring off the hook for near six-figure mega-Maxes, so in the meanwhile, he’s marketing some of the neater, smaller chunks of technology from his bike through Two Brothers Racing (1715 East Wilshire Ave., Unit 701, Santa Ana, CA 92705; 714/550-6070) in the U.S. Soon you’ll be able to buy the downdraft intake system with Keihin flat-slides, functional scoops, carbon-fiber airbox and cover-which in Kainzinger’s interpretation has actually become a one-gallon gas tank-as well as dyno-developed exhaust systems.

But we’re saving our money for something else: A plane ticket to Germany, and a chance to exercise our rain-check ride on the hottest hot-rod that has ever crossed our path.

View Full Issue

View Full Issue