SERVICE

Paul Dean

Fueling around

Recently, I tried to fill my KZ650 Kawasaki’s gas tank at a station that uses the new vapor-recovery systems, and the nozzle would not go into the tank far enough to seal the rubber boot. So, I could not get the pump to work. If you have any suggestions about how to deal with this refueling problem, they would be greatly appreciated. David J. Basore

Harrisburg, Pennsylvania

Vapor-recovery nozzles have been mandatory in many large metropolitan areas-including here in Southern California-for more than a decade. They are only new in less-populated or rural regions that are being forced into adopting them to comply with evermore-stringent air-quality standards.

For those of you who don’t already know, the nozzles Mr. Basore is referring to are designed to capture and recirculate the gasoline vapors given off as fuel is pumped into a vehicle at a ser-

vice station. A vapor-recovery nozzle differs from a conventional type in that its steel filler tube (the part inserted into a vehicle ’s gas tank) is surrounded by a loose-fitting, accordion-pleated rubber sheath connected to a second

hose that leads back to the station ’s underground storage tank. Inside the sheath is a coil spring that, when sufficiently compressed, trips a lever up near the fuel-delivery handle that allows the handle to function.

Thus, for the nozzle to operate, the delivery tube must be inserted into the gas tank far enough to compress the sheath spring to the point where it activates the fuel-flow handle. And because the open end of the sheath is pressed tightly against the vehicle’s fuel-filler opening, any vapors are captured by the sheath and recirculated back to the underground storage tank via the return hose.

Unfortunately, the people who designed these nozzles didn’t figure motorcycles into the equation. On some bikes, the center hump of the gas tank is so close to the filler opening that the nozzle can’t penetrate far enough to compress the sheath and activate the handle. On tanks with flip-up caps, the cap often interferes with insertion of the nozzle. And even when you can get sufficient sheath compression against the filler opening, the nozzle usually protrudes so far into the filler neck that the tank can’t be completely topped up.

As a consequence, the only sure way to get fuel into your bike ’s tank is to defeat the nozzle in either of two ways. One is to grab the sheath at its open end and pull it up the nozzle tube until you compress the spring enough to activate the fuel-flow handle. Then, while holding the sheath in place, stick the nozzle into the tank and squeeze the handle. Or, if you want to avoid the possibility of getting gasoline on your hand, simply grab the outside of the sheath at its extreme upper end, just below the handle, and pull it toward the handle. This usually requires less force than the former method, for it bypasses the need to compress the entire spring, thereby eliminating virtually all of the friction between the rubber sheath and the steel filler tube.

Ticked-off Boxer

By the time my 1984 BMW R100 G/S turned 70,000 miles on the clock, the valves had been ticking pretty badly for quite some time, so I decided to adjust them myself instead of taking the bike to a dealer. I used the factory-recommended settings of .006” on the intakes and .008” on the exhausts, but was shocked to find that the ticking actually got louder after the adjustment. I went back and did it all again, carefully following the exact procedures described in my shop manual, but the ticking still was louder than before. I then started>

playing around with different settings and found that tightening up the clearances got rid of most of the ticking. Why did the noise get worse after I adjusted the valves to the factory specs? Will the tighter clearances I’m now using hurt anything?

Gregory Pinsonnault Hamilton, Ontario, Canada

I can’t advise you about the effects of the current valve settings on your BMW because I don’t know how much you have reduced the clearances. But if the valves are now operating with only a fraction of their required clearance, they could quickly be burned badly enough to have serious detrimental effects on engine performance. Repairs could easily entail a complete valve job, including replacement of all or most of the valves.

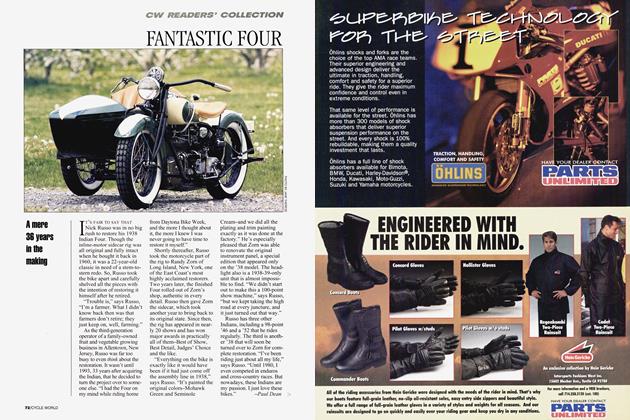

I also can only speculate about the cause of the ticking noises you describe. Quite often, particularly when the valves have been allowed to operate with excessive clearances for many miles, the part of the valve train that pushes on the valve stem (which, in the case of a BMW pushrod Twin, is the rocker arm) wears unevenly, usually in the form of a slight depression that forms on the end of the stem, with a matching protrusion on the contact surface of the rocker arm.

When this type of wear occurs, you don 't get an accurate valve-clearance reading with a feeler gauge. As depicted in the illustration below, the flat blade of a feeler gauge cannot

measure the distance between two points of contact when one of those points is a depression; instead, the gauge measures the distance between the most protruding part of the rocker arm and the very top of the valve stem. That distance is shorter than

the distance between the two surfaces that actually make contact, which are the highest part of the protrusion on the rocker and the lowest part of the depression in the valve stem. I’ve encountered instances in which a feeler gauge of the correct thickness would fit perfectly between rocker and valve stem but the actual valve-to-rocker clearance (measured with a dial indicator) was almost twice as great.

If this type of wear is what has occurred with your Beemer’s engine, you have several alternatives: 1) Do nothing and wait until something fails; 2) use a dial indicator (and a little ingenuity in figuring out how to mount it) to measure the valve clearance with a high degree of accuracy; or 3) replace the affected valves and/or rockers. Obviously, the third alternative is the recommended one.

ET calls back

Your answer to the reader with spark problems on his 1968 Triumph (September, 1994) was correct as far as it went, but there’s a better way. It’s certainly possible to junk the dismal Lucas energy-transfer system and retrofit the original Lucas battery ignition, but the owner of an older bike will get much better results by junking the mechanical breaker-points system altogether and fitting a Boyer electronic ignition kit. These have no moving parts, are far more reliable, and give a hotter spark. Before I put a Boyer system on my ’72 Norton Commando, I seemed to be fiddling with the damned Lucas points every few hundred miles. But I just recently adjusted my Boyer’s ignition timing for the first time after installing it-6000 miles ago.

Boyer ignition kits are available to fit British, German, Italian and many Japanese motorcycles. They cost less than $150 and don’t change the appearance of the bike at all. For anyone with a broken points-based system, a Boyer ignition is a much better buy than replacing the stock components. Mike Taglieri

New York, New York

Thanks for the tip, Mike. I was fully aware of the Boyer ignition possibility when answering Mr. Creft’s letter but chose to give him the most direct reply to his inquiry. By the way, the people at Boyer say that your salescommission check is in the mail. □

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontIncident On the Angeles Crest

November 1994 By David Edwards -

Leanings

LeaningsGs-Ing It

November 1994 By Peter Egan -

TDC

TDCEngine Architecture

November 1994 By Kevin Cameron -

Letters

LettersLetters

November 1994 -

Roundup

RoundupAprilia Reveals Trick 250

November 1994 By Robert Hough -

Roundup

RoundupSuzuki Gets Savage For 1995

November 1994