TDC

The powerband puzzle

Kevin Cameron

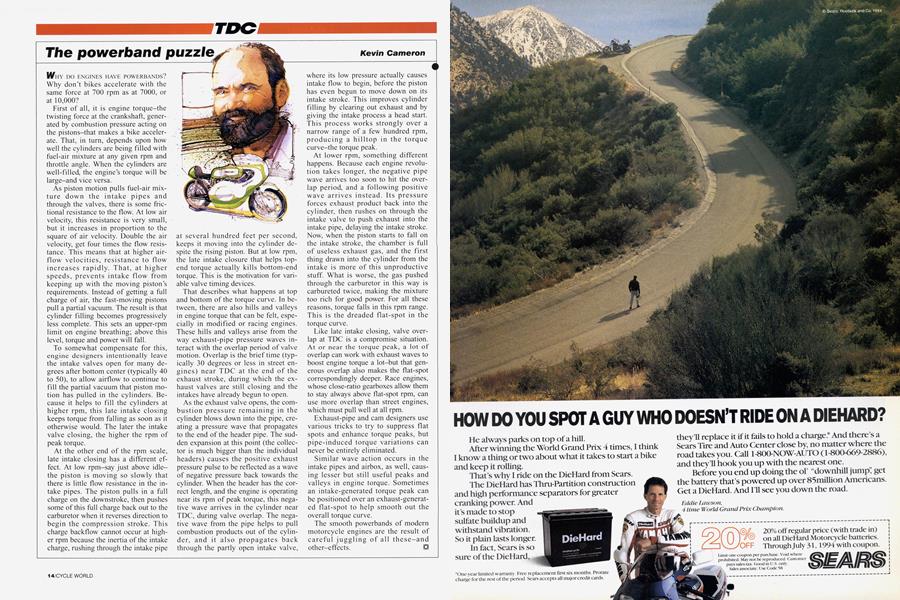

WHY DO ENGINES HAVE POWERBANDS? Why don't bikes accelerate with the same force at 700 rpm as at 7000, or at 10,000? First of all, it is engine torque—the twisting force at the crankshaft, generated by combustion pressure acting on the pistons—that makes a bike accelerate. That, in turn, depends upon how well the cylinders are being filled with fuel-air mixture at any given rpm and throttle angle. When the cylinders are well-filled, the engine's torque will be large-and vice versa.

As piston motion pulls fuel-air mixture down the intake pipes and through the valves, there is some frictional resistance to the flow. At low air velocity, this resistance is very small, but it increases in proportion to the square of air velocity. Double the air velocity, get four times the flow resistance. This means that at higher airflow velocities, resistance to flow increases rapidly. That, at higher speeds, prevents intake flow from keeping up with the moving piston’s requirements. Instead of getting a full charge of air, the fast-moving pistons pull a partial vacuum. The result is that cylinder filling becomes progressively less complete. This sets an upper-rpm limit on engine breathing; above this level, torque and power will fall.

To somewhat compensate for this, engine designers intentionally leave the intake valves open for many degrees after bottom center (typically 40 to 50), to allow airflow to continue to fill the partial vacuum that piston motion has pulled in the cylinders. Because it helps to fill the cylinders at higher rpm, this late intake closing keeps torque from falling as soon as it otherwise would. The later the intake valve closing, the higher the rpm of peak torque.

At the other end of the rpm scale, late intake closing has a different effect. At low rpm-say just above idle— the piston is moving so slowly that there is little flow resistance in the intake pipes. The piston pulls in a full charge on the downstroke, then pushes some of this full charge back out to the carburetor when it reverses direction to begin the compression stroke. This charge backflow cannot occur at higher rpm because the inertia of the intake charge, rushing through the intake pipe at several hundred feet per second, keeps it moving into the cylinder despite the rising piston. But at low rpm, the late intake closure that helps topend torque actually kills bottom-end torque. This is the motivation for variable valve timing devices.

That describes what happens at top and bottom of the torque curve. In between, there are also hills and valleys in engine torque that can be felt, especially in modified or racing engines. These hills and valleys arise from the way exhaust-pipe pressure waves interact with the overlap period of valve motion. Overlap is the brief time (typically 30 degrees or less in street engines) near TDC at the end of the exhaust stroke, during which the exhaust valves are still closing and the intakes have already begun to open.

As the exhaust valve opens, the combustion pressure remaining in the cylinder blows down into the pipe, creating a pressure wave that propagates to the end of the header pipe. The sudden expansion at this point (the collector is much bigger than the individual headers) causes the positive exhaust pressure pulse to be reflected as a wave of negative pressure back towards the cylinder. When the header has the correct length, and the engine is operating near its rpm of peak torque, this negative wave arrives in the cylinder near TDC, during valve overlap. The negative wave from the pipe helps to pull combustion products out of the cylinder, and it also propagates back through the partly open intake valve, where its low pressure actually causes intake flow to begin, before the piston has even begun to move down on its intake stroke. This improves cylinder filling by clearing out exhaust and by giving the intake process a head start. This process works strongly over a narrow range of a few hundred rpm, producing a hilltop in the torque curve-the torque peak.

At lower rpm, something different happens. Because each engine revolution takes longer, the negative pipe wave arrives too soon to hit the overlap period, and a following positive wave arrives instead. Its pressure forces exhaust product back into the cylinder, then rushes on through the intake valve to push exhaust into the intake pipe, delaying the intake stroke. Now, when the piston starts to fall on the intake stroke, the chamber is full of useless exhaust gas, and the first thing drawn into the cylinder from the intake is more of this unproductive stuff. What is worse, the gas pushed through the carburetor in this way is carbureted twice, making the mixture too rich for good power. For all these reasons, torque falls in this rpm range. This is the dreaded flat-spot in the torque curve.

Like late intake closing, valve overlap at TDC is a compromise situation. At or near the torque peak, a lot of overlap can work with exhaust waves to boost engine torque a lot-but that generous overlap also makes the flat-spot correspondingly deeper. Race engines, whose close-ratio gearboxes allow them to stay always above flat-spot rpm, can use more overlap than street engines, which must pull well at all rpm.

Exhaust-pipe and cam designers use various tricks to try to suppress flat spots and enhance torque peaks, but pipe-induced torque variations can never be entirely eliminated.

Similar wave action occurs in the intake pipes and airbox, as well, causing lesser but still useful peaks and valleys in engine torque. Sometimes an intake-generated torque peak can be positioned over an exhaust-generated flat-spot to help smooth out the overall torque curve.

The smooth powerbands of modern motorcycle engines are the result of careful juggling of all these-and other-effects.