SERVICE

Stopping short

In the interest of upgrading my Honda 1100’s braking system, I am looking for a company that drills front-brake rotors. Any suggestions?

Tyrone Mondesir Brooklyn, New York

Properly done, drilled brake rotors have two advantages: They are a little lighter and they are resistant to galling. But the stainless steels that the Japanese manufacturers use in their rotors is very difficult to drill. In fact, it is nearly impossible without proper tools, including a rigid drill press and carbide drill bits.

Spec II (9812 Glen Oaks Blvd., Sun Valley, CA 91352; 818/504-6364) has been drilling rotors for 10 years and does excellent work. Spec II will drill 96 1/4-inch, sharp-edged holes in each disc for about $40 per rotor. The sharpedged holes scrape the pads clean of debris and rotor-wear particles, resulting in an almost-polished surface.

BUI the Stripper

While trying to get my ’84 Kawasaki GPz750 ready for winter storage, I inadvertently stripped the first few threads of the right-inner sparkplug hole. I quickly rushed my damaged

steed to the local Kawasaki dealer, and he was able to put the plug back in. But he told me that if I ever take that plug out again, I’ll need to get the hole heli-welded to rethread it.

Also, some aluminum shavings had > fallen into the hole while I was busy stripping the threads, but the dealer said I shouldn’t worry about them because they’ll get blown out through the exhaust. Is this true, or will the shavings damage my cylinder? I know that some shavings fell in, but I’m not sure how many or how big.

Finally, if I decide to take off the cylinder head to get the plug hole fixed, should I also get a valve job, or would the bike really need one with only 21,000 miles on it? Durability is my main concern. William A. Beck Peachland, British Columbia, Canada

You seem to have confused “heliwelding” (as in heliarc) with a helicoil, which is an insert that puts new threads in a stripped hole. Welding is not a logical remedy unless the aluminum around the hole is cracked or the hole itself too badly destroyed for a helicoil to fit. Otherwise, a helicoil or one of several other similar threadrepair inserts is the preferred solution.

With any of these thread-repair processes, the affected hole is enlarged with an oversized drill, then rethreaded with an equally oversized tap. After that, the helicoil (which is, in effect, a specially designed coil spring that looks a lot like a small, fully compressed Slinky) or solidmetal insert is threaded into place. The hole is then repaired and ready to have the sparkplug screwed into place.

Since this process involves drilling the affected hole, you really should remove the head to prevent shavings from getting into the cylinder. Some people do install helicoils without removing the head; they try to keep shavings out of the cylinder by either turning the engine upside-down while drilling the hole, or by removing the exhaust system and blowing highpressure air through the affected cylinder’s open exhaust valve while drilling. But the only sure-fire way to install a helicoil in a cylinder head without contaminating the cylinder is to remove the head.

If shavings do fall into the cylinder, they may or may not cause problems. If they aren’t too big or too many, they ’ll probably get blown out the exhaust as your dealer claims. Probably. But there ’s always a chance that the exhaust valve will close at the very instant one of those little bits of hot metal is moving past it, trapping the shaving between the valve face and the valve seat. The shaving can then get fused either to the valve or the seat, thereby preventing the valve from fully closing. And that, in turn, will cause a loss of compression and performance.

If you decide to remove the head to install the helicoil, the need for a valve job will be very easy to ascertain. If you choose not to remove the head, a leak-down test will help a knowledgeable mechanic determine if the valves are sealing properly. Either way, take heart in the fact that 21,000 miles is not a lot for a GPz750 if its engine has been properly maintained.

Slippery subject

I recently purchased a new Honda CBR900RR. Could you tell me how many miles I should put on it before I start to use synthetic oil?

David Doerges Palm Springs, Florida

Opinion is divided on this subject, but the consensus among the tuners and technicians we know is that an engine should be fully broken-in before it is run with synthetic oil. They believe that because synthetics have more molecular adhesion-"oiliness,” in lay language-than conventional oils, using them in a new engine can either greatly slow down the normal break-in process or practically stop it altogether. In the best case, complete engine break-in would simply take longer; in the worst case, the engine would never get fully broken-in and would still exhibit many of the same symptoms-a greater rate of blow-by, slight compression leakage, marginal power loss, etc.—as a brand-new or freshly rebuilt engine.

On the other hand, the oil manufacturers claim their synthetics cause no such break-in problems. So, if you don’t know who to believe, don’t take chances: Run your CBR900RR on a decent grade of mineral oil for at least the first 1000 miles before switching to a synthetic.

Fricasseed FJ filaments

My 1986 Yamaha FJ1200 has logged 24,000 trouble-free miles until just recently, when two seemingly separate problems started occurring. During a recent trip, the FJ burned out the running-light filaments of its front directional lights at the rate of about two a day. Since then, in my daily commute of 20 miles each way > to and from work, I’ll average about one burn-out a week, sometimes going through one a day, sometimes having one bulb last a week or more. No other bulbs are failing, and the problem is not inherent to either side.

The second problem is with the fuel gauge. While it never was highly accurate, it always was consistent. But lately, it will surge 30 to 40 percent high for a few minutes, then return to normal. This happens maybe twice in 100 miles. I’ve tried to determine if this surging and bulb failure occur at the same time but haven't had any success. Any ideas? Joseph Voskuil Janesville, Wisconsin

Electrical problems are hard to diagnose in person, virtually impossible by mail. But from 2000 miles away, it would seem your FJ1200’s electrical system is receiving an intermittent high-voltage increase from the alternator.

The tipoff is the surging of the fuel gauge, which moves its needle according to the amount of voltage it receives through a resistor built into the float in the fuel tank. The higher the voltage, the higher the gauge reads; so, the only way it can read 40 percent too high is to get 40 percent too much voltage. And the motorcycle 's only source of unusually high voltage (greater than the battery 's normal maximum of 13.2 volts) is the alternator.

It is probable, then, that this same voltage rise is what's been toasting the running-light bulbs. The reason why only those lights are affected is simple: Every different type of bulb on any motorcycle will tend to blow out at a different level of excess voltage. At one extreme, a headlight may be able to withstand, say, 17 volts, while at the other extreme, a runninglight filament might be able to deal with no more than 14 or 15 volts. Thus, if the voltage rise is greater than 15 but less than 17 volts, only the running lights would blow.

If this is the problem, the cause is most likely one of three possibles: a loose ground wire on the battery; an intermittent open circuit somewhere inside the battery; or an intermittent failure in the solid-state voltage regulator/rectifier. Based on the infrequency of this problem, however, be prepared to do some detective work to sleuth out its origin. □

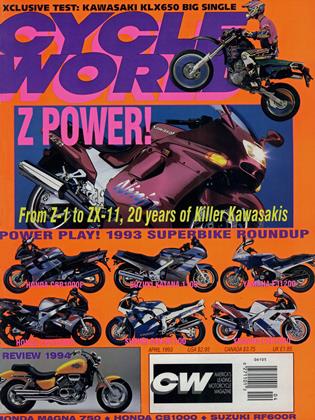

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontGreen Machines

April 1993 By David Edwards -

Leanings

LeaningsYou Ain't Goin' Nowhere

April 1993 By Peter Egan -

TDC

TDCSpring To Action

April 1993 By Kevin Cameron -

Letters

LettersLetters

April 1993 -

Roundup

RoundupYamaha To Go Standard?

April 1993 By Jon F. Thompson -

Roundup

RoundupBimota Presses On With Gp Streetbike

April 1993 By Alan Cathcart