ABS UP CLOSE

BETTER BRAKING THROUGH ELECTRONICS

KEVIN CAMERON

YOU SEE THE DOG AND THE sandy road surface at the same instant. With mixed fear and hope you "pump" the brakes, applying them to sense the grip, then releasing, then applying again in a rapidly repeating cycle. You do this to ensure that neither wheel locks on the slippery sand for more than an instant, keeping your motorcycle safely under directional control at both ends. This action requires skill and experience. You would do the same on any questionable surface-loose gravel, wet pavement, snow. An anti-lock brake system (ABS, from the German anti blockier system) is simply a very fast-reacting, sophisticated and automated means of performing this cycle.

ABS does not improve upon the drypavement stopping distances of highly experienced riders. What it does do is deliver consistently close-to-shortestpossible stopping distances, while maintaining control and stability. It does so on all types of surfaces-includ ing those normally too tricky for even the best of riders. This, in effect, makes "canned skill" of a high order available to all riders who take proper care in ABS use: Brake in a straight line if possible, and in corners only with normal caution. Do not expect ABS to perform miracles. Maintain safe braking margins at all times, as you would with non-ABS brakes.

In 1988, only one motorcycle maker, BMW, offered ABS. Now add two more; Honda and Yamaha. Automo tive systems have been in production since the 1970s, but the special nature of the motorcycle has delayed applica tion of ABS to two wheels. For the moment, it is interesting to compare the three systems on the market.

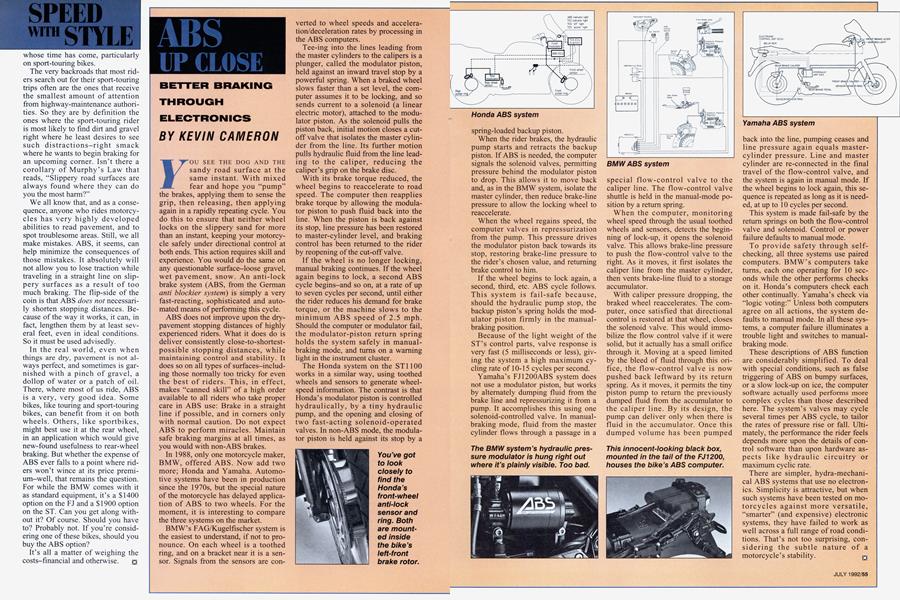

BMW's FAG/Kugelfischer system is the easiest to understand, if not to pro nounce. On each wheel is a toothed ring, and on a bracket near it is a sen sor. Signals from the sensors are converted to wheel speeds and accelera tionldeceleration rates by processing in the ABS computers.

Tee-ing into the lines leading from the master cylinders to the calipers is a plunger, called the modulator piston, held against an inward travel stop by a powerful spring. When a braked wheel slows faster than a set level, the com puter assumes it to be locking, and so sends current to a solenoid (a linear electric motor), attached to the modu lator piston. As the solenoid pulls the piston back, initial motion closes a cut off valve that isolates the master cylin der from the line. Its further motion pulls hydraulic fluid from the line lead ing to the caliper, reducing the caliper's grip on the brake disc.

With its brake torque reduced, the wheel begins to reaccelerate to road speed. The computer then reapplies brake torque by allowing the modula tor piston to push fluid back into the line. When the piston is back against its stop, line pressure has been restored to master-cylinder level, and braking control has been returned to the rider by reopening of the cut-off valve.

If the wheel is no longer locking, manual braking continues. If the wheel again begins to lock, a second ABS cycle begins-and so on, at a rate of up to seven cycles per second, until either the rider reduces his demand for brake torque, or the machine slows to the minimum ABS speed of 2.5 mph. Should the computer or modulator fail, the modulator-piston return spring holds the system safely in manual braking mode, and turns on a warning light in the instrument cluster.

The Honda system on the ST 1100 works in a similar way, using toothed wheels and sensors to generate wheelspeed information. The contrast is that Honda's modulator piston is controlled hydraulically, by a tiny hydraulic pump, and the opening and closing of two fast-acting solenoid-operated valves. In non-ABS mode, the modula tor piston is held against its stop by a spring-loaded backup piston.

When the rider brakes, the hydraulic pump starts and retracts the backup piston. If ABS is needed, the computer signals the solenoid valves, permitting pressure behind the modulator piston to drop. This allows it to move back and, as in the BMW system, isolate the master cylinder, then reduce brake-line pressure to allow the locking wheel to reaccelerate.

When the wheel regains speed, the computer valves in repressurization from the pump. This pressure drives the modulator piston back towards its stop, restoring brake-line pressure to the rider's chosen value, and returning brake control to him.

If the wheel begins to lock again, a second, third, etc. ABS cycle follows. This system is fail-safe because, should the hydraulic pump stop, the backup piston's spring holds the mod ulator piston firmly in the manual braking position.

Because of the light weight of the ST's control parts, valve response is very fast (5 milliseconds or less), giv ing the system a high maximum cy cling rate of 10-15 cycles per second.

Yamaha's H 1200ABS system does not use a modulator piston, but works by alternately dumping fluid from the brake line and repressurizing it from a pump. It accomplishes this using one solenoid-controlled valve. In manual braking mode, fluid from the master cylinder flows through a passage in a special flow-control valve to the caliper line. The flow-control valve shuttle is held in the manual-mode po sition by a return spring.

When the computer, monitoring wheel speed through the usual toothed wheels and sensors, detects the begin ning of lock-up, it opens the solenoid valve. This allows brake-line pressure to push the flow-control valve to the right. As it moves, it first isolates the caliper line from the master cylinder, then vents brake-line fluid to a storage accumulator.

With caliper pressure dropping, the braked wheel reaccelerates. The com puter, once satisfied that directional control is restored at that wheel, closes the solenoid valve. This would immo bilize the flow control valve if it were solid, but it actually has a small orifice through it. Moving at a speed limited by the bleed of fluid through this ori fice, the flow-control valve is now pushed back leftward by its return spring. As it moves, it permits the tiny piston pump to return the previously dumped fluid from the accumulator to the caliper line. By its design, the pump can deliver only when there is fluid in the accumulator. Once this dumped volume has been pumped back into the line, pumping ceases and line pressure again equals mastercylinder pressure. Line and master cylinder are re-connected in the final travel of the flow-control valve, and the system is again in manual mode. If the wheel begins to lock again, this se quence is repeated as long as it is need ed, at up to 10 cycles per second.

This system is made fail-safe by the return springs on both the flow-control valve and solenoid. Control or power failure defaults to manual mode:

To provide safety through selfchecking, all three systems use paired computers. BMW's computers take turns, each one operating for 10 sec onds while the other performs checks on it. Honda's computers check each other continually. Yamaha's check via "logic voting:" Unless both computers agree on all actions, the system de faults to manual mode. In all these sys tems, a computer failure illuminates a trouble light and switches to manual braking mode.

These descriptions of ABS function are considerably simplified. To deal with special conditions, such as false triggering of ABS on bumpy surfaces, or a slow lock-up on ice, the computer software actually used performs more complex cycles than those described here. The system's valves may cycle several times per ABS cycle, to tailor the rates of pressure rise or fall. Ulti mately, the performance the rider feels depends more upon the details of con trol software than upon hardware as pects like hydraulic circuitry or maximum cyclic rate.

There are simpler, hydra-mechani cal ABS systems that use no electron ics. Simplicity is attractive, but when such systems have been tested on mo torcycles against more versatile, "smarter" (and expensive) electronic systems, they have failed to work as well across a full range of road condi tions. That's not too surprising, con sidering the subtle nature of a motorcycle's stability.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontAndy Rooney Rides

July 1992 By David Edwards -

Leanings

LeaningsThe Whites of Their Eyes

July 1992 By Peter Egan -

TDC

TDCA Matter of A Pinion

July 1992 By Kevin Cameron -

Letters

LettersLetters

July 1992 -

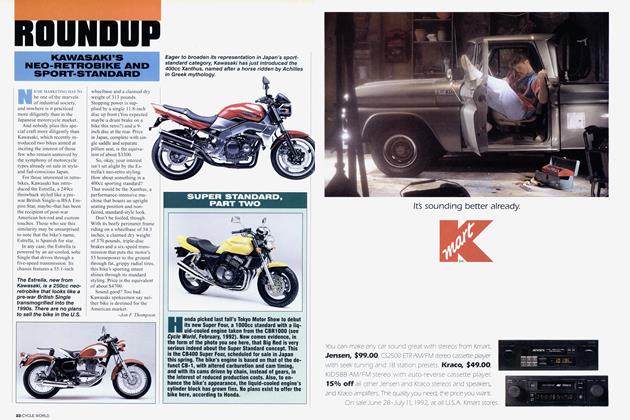

Roundup

RoundupKawasaki's Neo-Retrobike And Sport-Standard

July 1992 By Jon F. Thompson -

Roundup

RoundupSuper Standard, Part Two

July 1992